Centrifuging is a process that helps separate things. It is important to set the temperature at four degrees Celsius when using a centrifuge because it will help keep the particles or substances being separated from getting damaged or destroyed. This ensures that the experiment yields accurate results.

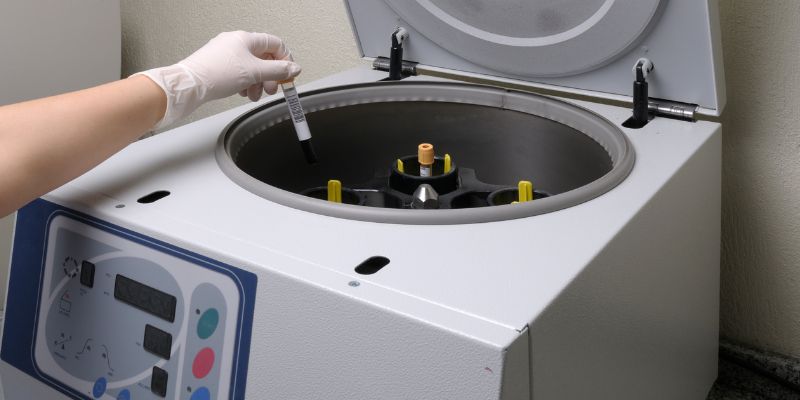

Centrifugation is a common scientific technique used in laboratories to separate substances of different densities and sizes. It is an essential tool in many scientific fields such as biochemistry, biotechnology, and molecular biology. Centrifuging at 4 degrees Celsius is an important step in many experiments because it can preserve sample integrity and reduce the risk of contamination. In this blog post, we will discuss the different types of centrifuges, common applications of centrifuging at 4 degrees, and the benefits, safety considerations, and troubleshooting methods associated with centrifuging at 4 degrees.

Types of Centrifuges

Centrifuges are powerful machines used in many industries for separating liquids, solids, and gases. They are used for a wide range of applications, from processing water for drinking to separating oil from sand. Depending on the application, there are several types of centrifuges available.

The most commonly used centrifuge is the refrigeration centrifuge. This type of centrifuge is used for separating liquids from solids at a temperature of 4°C. The refrigeration centrifuge is ideal for applications such as food processing, pharmaceuticals, biotechnology, and chemical industries. The refrigeration centrifuge is also used for DNA and protein isolates.

Another type of centrifuge is the high-speed centrifuge. This type of centrifuge is used for separating liquids from solids at high speeds. High-speed centrifuges are used in applications such as fuel processing, petroleum refining, and wastewater treatment.

The last type of centrifuge is the ultracentrifuge. This type of centrifuge is used for separating macromolecules such as proteins and DNA. Ultracentrifuges can spin at speeds up to 100,000 rpm. Ultracentrifuges are used in medical and scientific research, such as drug discovery and genetic engineering.

No matter what type of centrifuge you need for your application, the importance of using the correct temperature for the separation process cannot be overstated. Refrigeration centrifuges must be used at 4°C in order to ensure the best possible results. High-speed centrifuges should not be run at temperatures below 0°C, and ultracentrifuges should be used at temperatures between 15°C and 25°C.

By understanding the different types of centrifuges and the temperatures at which they should be used, you can ensure that you get the best possible results for your application.

Common Applications of Centrifugation at 4 Degrees

Centrifugation at 4 degrees is a key procedure in many scientific and medical applications. By subjecting a sample to high-speed rotation, the centrifugal force separates components that have different densities or sizes. This process is particularly useful when used at 4 degrees, as it helps to preserve delicate biological components such as proteins and enzymes. Here are some common applications of centrifugation at 4 degrees:

1. Tissue Preparation: Centrifugation at 4 degrees helps to separate cells and other solid components from liquids, making it an ideal preparation method for a variety of tissue samples. This is especially useful in medical research, where well-prepared samples can improve the accuracy of results.

2. Protein Purification: Proteins are highly sensitive and can be easily damaged or destroyed by high temperatures. By centrifuging at 4 degrees, proteins can be separated and purified without fear of denaturation.

3. DNA Analysis: DNA strands are easily damaged by exposure to heat and chemicals, so centrifugation at 4 degrees is often employed in genetic analysis. This helps preserve the integrity of the samples, ensuring accurate results.

4. Cell Separation: Centrifugation at 4 degrees is often used to separate different types of cells, such as healthy and diseased cells. This can be especially useful for medical diagnostics.

By centrifuging samples at 4 degrees, scientists and medical professionals can ensure that delicate components are preserved and accurately separated. This makes centrifugation at 4 degrees an invaluable tool for a variety of research and medical applications.

Benefits of Using a Centrifuge at 4 Degrees

Centrifuging at 4 degrees has many benefits when it comes to separating and purifying samples. This technique can be used to isolate biomolecules such as proteins, nucleic acids, and lipids from complex mixtures. Centrifugation at 4 degrees allows for a much more efficient and effective separation of these components. It also helps to remove contaminants from complex samples, which can make analysis and quantification of the desired components more accurate.

One of the primary benefits of centrifuging at 4 degrees is that it allows for a more gentle separation compared to higher temperatures. This reduces the risk of damage to the sample during the separation process. In addition, at lower temperatures, the sample components remain more stable, which helps to ensure accurate results.

Another advantage of centrifuging at 4 degrees is that it eliminates the need for additional purification steps. Centrifugation at this temperature allows for separation of the desired components in one step, which makes the overall process faster and more efficient. This also reduces the risk of contamination and helps to preserve the integrity of the sample.

Finally, centrifuging at 4 degrees is a cost-effective way to separate and purify samples. This is because the process requires less energy and fewer reagents than other purification methods, making it more affordable for laboratories and research facilities.

In summary, centrifuging at 4 degrees offers numerous advantages for sample separation and purification. This technique helps to preserve the sample integrity, eliminates the need for additional purification steps, and is both efficient and cost-effective. For these reasons, centrifugation at 4 degrees is the preferred method for many laboratories and research facilities.

Safety Considerations of Centrifugation at 4 Degrees

Centrifugation at 4 degrees is a common practice in many laboratories and research facilities. This temperature is used to maximize the separation of components in a sample, as it minimizes influences from temperature-induced convection and interference from molecules in solution. However, there are a few important safety considerations one should take into account when performing centrifugation at 4 degrees.

First, it is important to ensure that the centrifuge is properly maintained. Centrifuges operating at 4 degrees should be regularly inspected for any signs of wear and tear, and any components that are not functioning correctly should be replaced. Additionally, it is essential to wear protective clothing, such as gloves and goggles, to prevent any possible contact with the sample or the surrounding environment.

Second, it is important to be aware of the potential risks associated with centrifugation at 4 degrees. These include physical risks such as injury from spinning parts, and chemical risks such as exposure to hazardous substances. It is important to take the necessary precautions to ensure the safety of the user, including using proper shielding and wearing protective clothing.

Finally, it is important to ensure that the sample is properly prepared before centrifugation. Samples should be thoroughly mixed and homogenized, and any air bubbles should be removed to prevent the sample from being contaminated or damaged during centrifugation. Additionally, it is important to ensure that the sample is properly balanced and that the centrifuge is calibrated correctly for the specific sample being spun.

In conclusion, centrifugation at 4 degrees is an effective way to separate components in a sample, but it is important to take the necessary precautions to ensure the safety of the user and the sample. By following these safety considerations, you can ensure that your centrifugation process is safe and effective.

Selection of Appropriate Centrifuge Speed and Time

When selecting an appropriate centrifuge speed and time for a particular experiment, there are a few key considerations to take into account. Firstly, the centrifuge should be set to the minimum speed necessary to achieve the desired results. This is to ensure that the sample is not damaged or destroyed by the centrifugal force. Secondly, the speed should be set to the optimal temperature, which is generally 4 degrees Celsius. This temperature helps to ensure that proteins and other biological molecules are not denatured due to excess heat.

Moreover, the time should be set according to the type of experiment being conducted. For example, if the experiment requires separating out a sample into its components, the centrifuge should be set to a higher speed and a longer time in order to achieve this. On the other hand, if the experiment requires obtaining a pure sample from a mixture, the centrifuge should be set to a lower speed and a shorter time in order to avoid over-centrifugation.

Lastly, it is important to note that the speed and time should be adjusted to the specific experiment taking place. This is to ensure the most optimal results are achieved. Furthermore, it is also important to take into account any safety precautions that may be necessary when setting the centrifuge.

In conclusion, selecting an appropriate centrifuge speed and time is essential in order to achieve the desired results in an experiment. It is important to consider the speed, temperature, time and any safety precautions that may be necessary when setting the centrifuge. By doing so, experiments can be conducted with the highest accuracy and efficiency.

Analysis of Samples After Centrifugation

Centrifugation is an essential step in many laboratory protocols, and analyzing samples after centrifugation can provide valuable insights into their composition and structure. Centrifugation is used to separate components of a sample based on their density, allowing for more detailed analysis of the sample. Centrifugation is typically performed at 4°C, and this temperature is important for accurate analysis of the sample.

When analyzing samples after centrifugation, it is important to consider the effect of the temperature on the sample. At 4°C, the sample is kept in a state of equilibrium, meaning that each component of the sample is in its most stable state. This allows for more accurate analysis of the sample, as the components will not be affected by changes in temperature.

In addition, centrifugation at 4°C helps to ensure that components of the sample are not damaged. High temperatures can cause components of the sample to break down, which can lead to inaccurate results. By centrifuging the sample at 4°C, components of the sample are kept intact, allowing for a more accurate analysis.

Finally, centrifugation at 4°C helps to minimize the risk of contamination. By keeping the sample cold, the risk of contamination is minimized, as bacteria and other contaminants are less likely to survive in cold temperatures.

Overall, centrifugation at 4°C is an essential step in sample analysis, as it helps to ensure accurate results, minimize damage to components of the sample, and reduce the risk of contamination. By understanding the importance of this step and following best practices, sample analysis can be performed more accurately and efficiently.

Disadvantages of Centrifugation at 4 Degrees

Centrifugation at 4 degrees is a common technique used in laboratories to separate substances. However, there are some drawbacks to this method that must be considered before attempting it.

First, centrifugation at 4 degrees requires precise temperature control. This means that the lab environment must be kept at a consistent temperature or else the centrifuge may not be able to achieve the desired results. Additionally, the centrifuge must be properly calibrated to ensure accurate results.

Second, centrifugation at 4 degrees is a time-consuming process. It can take several hours to complete the process, depending on the size and amount of the sample. This makes it difficult to use in a time-sensitive setting and may require additional resources.

Third, centrifugation at 4 degrees is not always effective. Depending on the sample, the centrifugal force may not be strong enough to separate the desired components. This can lead to inaccurate results and require additional steps to be taken.

Finally, centrifugation at 4 degrees requires special equipment. This equipment can be expensive and difficult to maintain, making it a less cost-effective option for labs.

Despite these drawbacks, centrifugation at 4 degrees is still a valuable tool for many labs. By understanding the potential drawbacks and taking the necessary precautions, labs can use this technique effectively and efficiently.

Troubleshooting for Centrifugation

Centrifugation is a crucial process used in many scientific and medical applications, from separating cells to testing for the presence of viruses and other pathogens. However, if centrifugation is not performed correctly, it can lead to inaccurate results or even damage to the equipment. To ensure successful centrifugation, it is important to understand the basics of troubleshooting.

One of the most important troubleshooting tips for centrifugation is to ensure the sample is kept at the correct temperature. Most centrifuges operate best at 4 degrees Celsius, as this temperature is ideal for maintaining the integrity of samples. Additionally, some centrifuges have a maximum temperature of 4 degrees Celsius, so it is important to make sure the sample is at this temperature to avoid overheating the machine.

It is also important to check the rotor speed before centrifuging. Rotor speed can vary depending on the type of centrifuge and the type of sample being spun. If the speed is too high, it can cause the sample to become unstable and lead to inaccurate results. As a general rule, the rotor speed should be between 1000-3000 revolutions per minute (RPM).

When troubleshooting centrifugation, it is also important to check the rotor balance. If the rotor is not balanced, it can cause the sample to become unevenly distributed and lead to inaccurate results. If the rotor is not balanced, it is recommended to adjust the rotor until it is balanced before centrifuging.

Finally, it is important to make sure the sample is properly prepared before centrifugation. If the sample is not properly prepared, it can lead to inaccurate results or damage to the centrifuge. Make sure the sample is free of clumps and debris, and that the sample is mixed evenly before centrifugation.

By following these troubleshooting tips, you can ensure successful centrifugation and accurate results. If you have any questions or concerns about centrifugation, it is best to consult a professional for assistance.

Conclusion

In conclusion, centrifuging at 4 degrees Celsius is an effective way to separate particles, such as proteins and other macromolecules, from a mixture while preserving their properties. It is an important technique that is used in a variety of fields, including biochemistry and genetics. Centrifuging at 4 degrees Celsius has numerous benefits, including increased efficiency and safety. However, it is important to select the appropriate centrifuge speed and time in order to ensure the best results. Additionally, it is important to analyze the samples after centrifugation and to troubleshoot if necessary.

Related Post: