A high pressure reciprocating pump is used in HPLC. This pump works by making a vacuum and then quickly pushing the liquid to make pressure which moves the liquid through the system.

High-performance liquid chromatography (HPLC) is an analytical technique used to separate, identify, and quantify substances in a mixture. It is used in a variety of industries, such as pharmaceuticals, biotechnology, food and beverage, and environmental sciences. One of the key components of HPLC is the pump, which is responsible for delivering the mobile phase to the column for sample analysis. In this blog post, we will discuss the different types of pumps used in HPLC, advantages of using HPLC pumps, and how to select the right pump for HPLC.

Advantages of HPLC

High Performance Liquid Chromatography (HPLC) is a powerful and versatile analytical tool used to separate, identify and quantify compounds in a variety of sample types. HPLC is a technique that offers several advantages over other forms of chromatography, including faster analysis times and the ability to detect a wider range of compounds. Additionally, HPLC systems are highly customizable, allowing users to tailor their systems to specific needs.

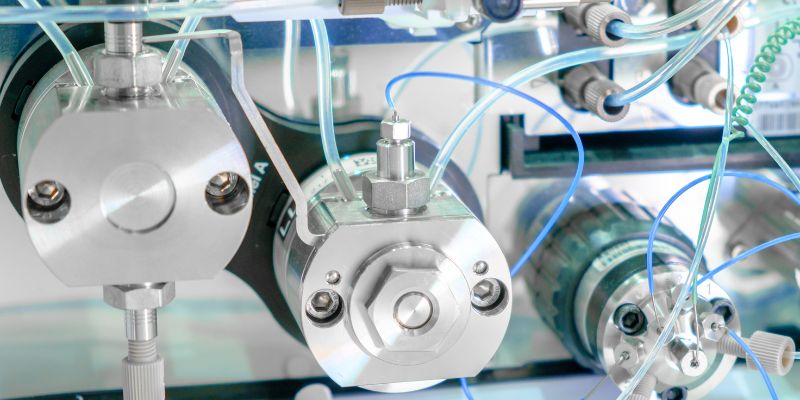

One of the key components of any HPLC system is the pump, which is responsible for providing a steady flow of liquid chromatography (LC) mobile phase. While there are a few different types of pumps used in HPLC, the most common are reciprocating pumps, which use a piston to generate a pulsating flow. This type of pump is advantageous in HPLC systems because it offers precise control over flow rate and pressure, and it is also able to generate a constant flow rate over a wide range of pressures. This makes it ideal for applications where flow rate is critical, such as when using small particle columns or when analyzing compounds with a high affinity for the stationary phase.

Another advantage of using a reciprocating pump in an HPLC system is that it is relatively easy to maintain and repair. This makes it ideal for users who may not have access to specialized technicians or parts. Additionally, these pumps are typically quite reliable and can withstand years of use without needing to be replaced.

Finally, reciprocating pumps are often very cost-effective, making them a great choice for those who are looking to save money while still achieving excellent chromatographic performance.

In conclusion, reciprocating pumps are a great choice for HPLC systems due to their ability to provide precise control over flow rate and pressure, their ease of maintenance and repair, and their cost-effectiveness.

Different Types of Pumps Used in HPLC

To answer this question, it is important to understand the different types of pumps used in HPLC and the most commonly used pumps in HPLC.

Types of Pumps Used in HPLC

When it comes to HPLC (High Performance Liquid Chromatography), choosing the right type of pump is essential for successful results. There are a variety of pumps used in HPLC, each of which offers its own unique features and capabilities. To help you decide which type of pump is best for your HPLC application, let’s take a look at the different types of pumps used in HPLC.

One of the most common types of pumps used in HPLC is the syringe pump. Syringe pumps are ideal for precise and accurate control of flow rate and pressure, making them a popular choice for many HPLC applications. Syringe pumps use a syringe filled with a sample solution and a plunger to push liquid through the HPLC system.

Another popular type of pump for HPLC is the diaphragm pump. Diaphragm pumps use a diaphragm to create a vacuum, which draws liquid into the HPLC system. Diaphragm pumps offer a high degree of accuracy and control, making them ideal for precise HPLC applications.

A third type of pump used in HPLC is the peristaltic pump. Peristaltic pumps use an internal roller to compress a flexible tube, forcing liquid through the HPLC system. Peristaltic pumps are very efficient, and are often used in applications that require a large volume of liquid.

Finally, a fourth type of pump used in HPLC is the piston pump. Piston pumps use a piston to push liquid through the HPLC system. Piston pumps are capable of producing high pressures and are often used in applications that require a large volume of liquid.

No matter which type of pump you choose for your HPLC application, it’s important to ensure that you select the right pump for the job. Each type of pump offers its own unique benefits and capabilities, so it’s important to consider your specific application before making a decision.

Commonly Used Pumps in HPLC

When it comes to HPLC, there are several types of pumps that are commonly used, each of which has its own set of advantages and disadvantages. The most common pumps used in HPLC include syringe pumps, diaphragm pumps, and piston pumps. Each of these pumps offers different benefits depending on the type of analysis that is being conducted.

Syringe pumps are used for low-pressure applications and are generally used for the injection of sample solutions. Their main advantage is that they are easy to use and are less costly than other pumps. However, they are limited in their ability to handle high-pressure applications.

Diaphragm pumps are typically used for high-pressure applications and can be used for both sample injection and mobile phase delivery. They are more expensive than syringe pumps, but they are more precise and can handle greater pressures.

Piston pumps are the most precise pumps used in HPLC and are used for high-pressure applications. They are the most expensive type of pump, but they can handle the highest pressures and are the most accurate.

In conclusion, HPLC pumps come in a variety of types, each with its own set of advantages and disadvantages. The most commonly used pumps in HPLC are syringe pumps, diaphragm pumps, and piston pumps. Depending on the type of analysis being conducted, different pumps may be more suitable. It is important to research the different types of pumps available and determine which one is best suited for your application.

Advantages of Using HPLC Pumps

HPLC pumps offer a variety of advantages, the most notable being their key features.

Key Features of HPLC Pumps

When it comes to performing high-performance liquid chromatography (HPLC), one of the key components is the pump. HPLC pumps are designed to provide accurate, reproducible, and reliable results. Their main features include:

First and foremost, HPLC pumps are designed to provide precise and reproducible flow rates. The flow rate of the pump can be adjusted to deliver a specific amount of liquid, making it possible for researchers to accurately measure the amount of liquid passing through the system.

Another key feature of HPLC pumps is their ability to handle a wide range of pressures. This ensures that the system is able to handle a variety of samples and different conditions. By being able to withstand higher pressures, HPLC pumps are able to deliver consistent and reliable results.

The pumps are also designed to protect the system from contamination. The pumps are designed to prevent the liquid from coming into contact with outside contaminants and to keep the system clean. This helps to ensure that the samples being tested remain free from contamination.

Finally, HPLC pumps are designed to be energy efficient. The pumps are designed to minimize power consumption, making them an ideal choice for laboratories that need to reduce their energy costs.

These are just a few of the key features of HPLC pumps that make them an ideal choice for scientists and researchers. With their ability to provide accurate and reproducible results, protect the system from contamination, and minimize power consumption, HPLC pumps are the perfect choice for any laboratory.

How to Select the Right Pump for HPLC

To help determine which pump is best for your HPLC system, you’ll need to consider a few factors, such as the type of pump, what potential issues you might encounter, and how best to maintain and care for the pump.

Factors to Consider When Choosing an HPLC Pump

When selecting a pump for High-Performance Liquid Chromatography (HPLC), there are several factors to consider. From the type of pump needed to the flow rate and pressure requirements, understanding which type of pump is best suited for a particular application can help ensure the most successful results.

The type of pump used in HPLC is typically a reciprocating piston or diaphragm pump. Piston pumps are typically used for low pressure applications and are ideal for applications requiring precise and accurate flow control. Diaphragm pumps, on the other hand, are designed for higher pressure applications, such as those used in UHPLC (Ultra High Performance Liquid Chromatography).

In addition to the type of pump, other factors to consider include the flow rate, pressure requirements, and accuracy of the pump. The flow rate should be determined based on the sample size and sample volumes used in the application. Pressure requirements should be selected based on the type of sample being analyzed and the type of chromatographic column used. Lastly, accuracy is important for obtaining reliable and reproducible results.

By taking into account these factors when selecting an HPLC pump, researchers can ensure they are using the most appropriate pump for their application. Choosing the right pump for HPLC can help ensure the best possible results.

Troubleshooting Common HPLC Pump Issues

When it comes to troubleshooting common HPLC pump issues, it is important to select the right pump for your specific application. Different pumps have different capabilities, and it is important to select the one that is best suited for the type of analysis you are performing. In general, an HPLC pump is a device used to push liquids through a system at a set pressure and flow rate. It is important to select the right pump for your specific application in order to ensure accurate and reliable results.

Common issues that can arise when using an HPLC pump include poor flow control, poor pressure control, poor linearity, and poor repeatability. In order to ensure accurate results, it is important to ensure that the pump is properly calibrated and maintained. Additionally, the pump should be regularly inspected to make sure that it is free from any leaks or blockages.

When troubleshooting common HPLC pump issues, it is important to understand the type of pump being used. There are three main types of pumps used for HPLC: positive displacement pumps, syringe pumps, and gear pumps. Positive displacement pumps use a piston or plunger to push a fixed volume of liquid through the system, while syringe pumps use a syringe-like device to do the same. Gear pumps use a rotating gear to push liquid through the system.

In order to ensure accurate and reliable results, it is important to select the right pump for your specific application. Additionally, it is important to ensure that the pump is properly calibrated, inspected, and maintained on a regular basis. By doing so, you can ensure that you are able to troubleshoot common HPLC pump issues quickly and easily.

Maintenance and Care of HPLC Pumps

When selecting the right pump for HPLC, it is important to understand the importance of regular maintenance and care of the pumps. Proper maintenance and care of HPLC pumps will ensure that they are operating at their peak performance and can help to extend their lifespan. Below we will discuss tips for maintenance and care of HPLC pumps.

First, it is important to select the right type of pump for the job. HPLC pumps are available in a variety of types, such as syringe pumps, piston pumps, diaphragm pumps, and more. It is important to select a pump that is suitable for the application, as each type of pump has different characteristics and capabilities.

Once the correct pump has been selected, it is important to maintain and care for the pump in order to ensure its optimal performance. This can include regular cleaning, lubrication, and inspections. Cleaning the pump regularly will help to remove any buildup that can cause performance issues. Lubrication should be done according to the manufacturer’s instructions to ensure that the pump’s moving parts are properly lubricated. Finally, inspections should be done regularly to identify any potential problems.

In addition to regular maintenance and care of the HPLC pump, it is important to select the right accessories. This includes selecting the right tubing and fittings, as well as the right filter. It is also important to select the right type of solvent for the application.

Finally, it is important to understand the basic principles of HPLC, such as chromatography and flow rates. Understanding these principles can help to ensure that the pump is used in the most efficient and effective manner.

By following these tips for the maintenance and care of HPLC pumps, you can ensure that your HPLC system is performing at its peak performance and can help extend its lifespan.

Conclusion

In conclusion, HPLC pumps are an essential component in the operation of HPLC systems, as they are responsible for propelling the solvent through the system and ensuring the accurate and precise analysis of samples. Different types of pumps are used in HPLC systems, such as mechanical, isocratic, and gradient pumps. Mechanical pumps are typically used for low-pressure applications, while isocratic and gradient pumps are used for high-pressure applications. When selecting the right pump for HPLC, it is important to consider factors such as pressure requirements, sample size, and flow rate. Regular maintenance and troubleshooting of HPLC pumps will help ensure accurate and reliable analysis of samples.

Related Post: