NPSH stands for Net Positive Suction Head and it is a measure of the pressure available at the pump’s suction port. It is important for a pump to work properly and efficiently. To calculate NPSH, you need to subtract the vapor pressure of the liquid being pumped from the pressure at the pump’s suction port. If the result is negative, then the pump will cavitate and not work properly. If the result is positive, the pump will be able to work properly and efficiently. Cavitation can cause damage to the pump.

Pumps are an essential part of many industrial operations, providing a means to move liquids or gases from one area to another. In order to operate reliably and efficiently, pumps require a certain amount of suction pressure and head losses to be maintained. One of the most important factors in this regard is the Net Positive Suction Head (NPSH). NPSH is a measure of the amount of suction pressure available to the pump, and the head losses due to friction and other factors in the suction line. This article will explain what NPSH is, how it is used in pump operation, different types of NPSH, sources of NPSH losses, their effect on pump performance, how to calculate NPSH requirements for a specific pump, and the importance of understanding and managing NPSH levels in order to ensure optimal pump performance.

Definition of NPSH

NPSH or Net Positive Suction Head is an important factor to consider when operating a centrifugal pump. It is the minimum inlet pressure that is required to prevent cavitation in the pump. Cavitation occurs when the pressure of the liquid in the pump drops below its vapor pressure, causing air bubbles to form in the liquid. This can lead to damage to the pump’s impeller and other components.

To calculate NPSH, you must first consider the available NPSHA, or Net Positive Suction Head Available. This is the inlet pressure of the liquid entering the pump, minus the pressure created by the surface tension of the liquid. The NPSHA must be greater than the NPSHR, or Net Positive Suction Head Required, for the pump to operate without cavitation. The NPSHR is the pressure required to prevent cavitation, which is determined by the pump manufacturer.

In order to ensure the pump is operating without cavitation, it is important to monitor both the NPSHA and the NPSHR. If the NPSHA is too low, it can be increased by increasing the inlet pressure of the liquid or by reducing the surface tension of the liquid. If the NPSHR is too high, it can be reduced by increasing the size of the impeller or by reducing the speed of the pump.

By understanding the importance of NPSH and how to calculate it, you can ensure your pump is operating efficiently and safely. Understanding NPSH can also help you select the right pump for your application, as the NPSHR must be taken into account when selecting a pump.

Different Types of NPSH

When it comes to pumps, one of the most important parameters to consider is the Net Positive Suction Head (NPSH). This is a term that describes the pressure drop that occurs between the location of the pump’s suction flange and the point of liquid entry. Pumps require a certain amount of NPSH to operate properly, and understanding the two types of NPSH is key to ensuring optimal performance.

The two types of NPSH are NPSH Available (NPSHa) and NPSH Required (NPSHr). NPSHa is the amount of NPSH that is available at the point of liquid entry, and it is determined by the physical characteristics of the system that the pump is operating in. It is important to note that NPSHa is typically lower than the NPSHr, and if the NPSHa is too low, the pump will not be able to operate correctly.

NPSHr, on the other hand, is the amount of NPSH required by the pump itself in order to function correctly. This is determined by the design of the pump and the type of liquid it is pumping. NPSHr is typically higher than NPSHa, and if the NPSHr is too high, the pump will not be able to operate correctly.

In order for a pump to operate properly, it is important to ensure that the NPSHa is at least equal to the NPSHr. If the NPSHa is lower than the NPSHr, then the pump will not be able to operate correctly and could potentially be damaged.

Understanding the differences between NPSHa and NPSHr is key to ensuring that your pump is operating correctly and efficiently. By taking the time to understand these parameters and making sure that they are properly balanced, you can help ensure that your pump is running optimally and avoid any potential damage.

Understanding Suction Pressure and Head Losses

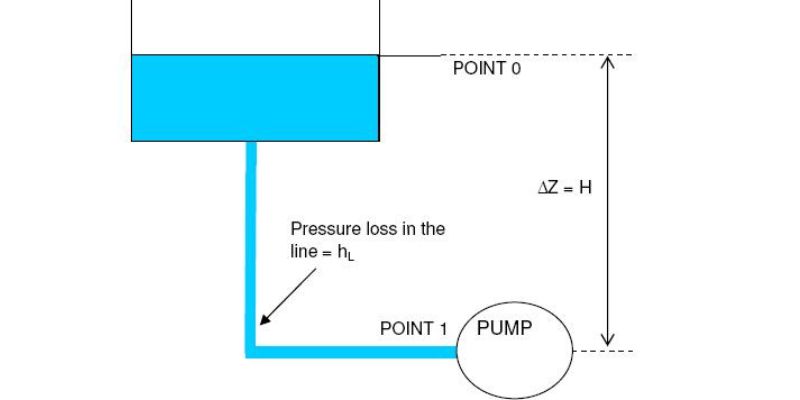

When dealing with pumps, it is important to understand both suction pressure and head losses and how they can affect the NPSH (Net Positive Suction Head) of a pump. NPSH is the minimum pressure required at the pump suction in order to prevent cavitation and is a major factor in pump selection.

Suction pressure is the pressure of the fluid at the pump’s suction and is usually measured in bar or psi. The pressure at the suction of the pump must be higher than the vapor pressure of the fluid to prevent cavitation. Head losses are the pressure losses in the system due to friction, bends, valves, etc. and these losses must be accounted for in order to ensure that the NPSH of the pump is not exceeded.

When calculating NPSH, the suction pressure and head losses must be taken into consideration. Generally, the higher the suction pressure, the lower the NPSH required. However, head losses can reduce the available NPSH and must be taken into account when selecting a pump. It is important to note that the NPSH must not be exceeded, as this can cause cavitation and cause damage to the pump.

In conclusion, when it comes to understanding suction pressure and head losses and how they affect the NPSH of a pump, it is important to consider both factors and make sure that the NPSH of the pump is not exceeded. The suction pressure and head losses must be taken into account when selecting a pump to ensure that the pump can operate without cavitation.

Sources of NPSH Losses

NPSH (Net Positive Suction Head) is a measure of the amount of pressure available at the suction side of a pump to provide liquid to the pump. It is an important measure that determines the efficiency of a pump and its ability to perform properly. In order for a pump to function properly, there must be sufficient NPSH available in order to move the liquid through the pump.

Unfortunately, there are several factors that can lead to losses of NPSH and thus reduce the efficiency of a pump. These factors can include piping design, installation, and operating conditions. Inadequate pipe size, elbows, valves, and other fittings can create resistance to flow, resulting in NPSH losses. In addition, turbulence created by the pump can also lead to NPSH losses.

Improper installation of the pump or operating the pump at high speeds can also lead to NPSH losses. If the pump is installed too close to the suction source or with an inadequate NPSH margin, the pump can become starved for liquid and cause NPSH losses. Additionally, running the pump at higher speeds than recommended can cause the impeller to cavitate, resulting in the formation of air bubbles that can further reduce NPSH.

Finally, if the suction source has inadequate pressure or the suction piping is too long, this can also cause NPSH losses. If the pressure of the suction source is too low, the pump may not be able to draw enough liquid into the system. Similarly, if the suction piping is too long, the pressure drop along the pipe can cause NPSH losses.

By understanding the sources of NPSH losses, it is possible to take steps to reduce or eliminate them. Proper sizing and installation of the pump and its associated piping are essential for proper operation. In addition, operating the pump at the correct speed and ensuring that the suction source has adequate pressure can help to ensure that the pump is able to perform efficiently.

Effects of NPSH on Pump Performance

The performance of a pump is heavily dependent on the Net Positive Suction Head (NPSH) available. This is the pressure difference between the inlet and the vapor pressure of the liquid. The NPSH is an important factor in determining the efficiency of a pump, and it is also closely linked to the phenomenon of cavitation.

Cavitation occurs when the pressure in the suction line of the pump drops below the vapor pressure of the liquid. This causes the liquid to form bubbles, or cavities, which then collapse when the pressure increases again. This process causes turbulence and vibration, which can significantly reduce the efficiency of the pump.

The NPSH available is the difference between the pressure in the suction line and the vapor pressure of the liquid. A low NPSH value can lead to cavitation, while a high value can reduce the risk of cavitation and improve pump efficiency.

The effects of NPSH on a pump’s performance can be seen in several ways. Firstly, it can reduce the life of the pump by increasing wear and tear due to the turbulence and vibration caused by cavitation. Secondly, it can reduce efficiency by reducing the pressure of the pump and reducing the flow rate.

In conclusion, the NPSH of a pump is an important factor in determining the pump’s performance. A low NPSH can lead to cavitation, reducing efficiency and increasing the risk of wear and tear. By ensuring that the NPSH is within the acceptable range, pump performance can be maximized and cavitation minimized.

Calculating NPSH Requirements for a Specific Pump

When it comes to choosing the right pump for your application, one of the most important considerations is the Net Positive Suction Head (NPSH) required by the pump. The NPSH of a pump is the difference between the suction pressure of the liquid at the suction port of the pump and the vapor pressure of the liquid at the same temperature. The greater the NPSH requirement of a pump, the higher the suction pressure must be to operate the pump properly.

In order to determine the NPSH requirement of a specific pump, it is important to understand the concept of NPSH and how it is calculated. NPSH is calculated by subtracting the vapor pressure of the liquid at the suction port of the pump from the suction pressure of the liquid at the same temperature. The vapor pressure of a liquid is the pressure at which it begins to evaporate, and it is typically measured in pounds per square inch (psig).

Once the vapor pressure is known, the NPSH requirement for a given pump can be determined by subtracting the vapor pressure from the suction pressure of the liquid at the same temperature. The result is the NPSH requirement for the pump, which must be met in order for the pump to operate properly.

It is important to understand the NPSH requirement of a specific pump in order to ensure that the pump is suitable for the application. If the NPSH requirement of the pump is not met, the pump may not be able to operate properly and can lead to inefficiencies and failure.

By understanding the concept of NPSH and how it is calculated, you can easily determine the NPSH requirement of a given pump and make sure that the pump is suitable for your application.

NPSH Margin

NPSH stands for Net Positive Suction Head, and it is a measure of the pressure difference between the pressure found at the suction side of the pump and the vapor pressure of the liquid being pumped. In order to ensure the proper operation of a pump, it is important to ensure that the NPSH margin is sufficient to prevent cavitation. Cavitation is when the pressure difference is so low that the liquid being pumped vaporizes and causes damage to the pump.

Calculating an appropriate NPSH margin is not a simple task, as it depends on several factors, such as the pump design, the liquid being pumped, and the operating conditions. Generally, the NPSH margin should be at least 10% higher than the NPSH required for the pump. This means that the pressure at the suction side of the pump should be at least 10% above the vapor pressure of the liquid being pumped.

To calculate the NPSH margin, you must first calculate the NPSH required for the pump. This can be done by using a pump curve, which will give you the required NPSH for different flow rates. Once the NPSH required has been calculated, you can then add 10% to it to determine the minimum NPSH margin.

In conclusion, it is important to ensure that the NPSH margin is sufficient to prevent cavitation. To ensure this, the NPSH margin should be at least 10% higher than the NPSH required for the pump. This can be calculated by using a pump curve, which will give you the required NPSH for different flow rates, and then adding 10% to it to determine the minimum NPSH margin.

Troubleshooting NPSH Issues with Pumps

No matter what type of pump you own, you may encounter NPSH issues during its operation. NPSH stands for Net Positive Suction Head, which is a measure of the pressure available at the suction port of a pump. If the NPSH is too low, the pump may not be able to perform properly. In this blog, we will discuss how to identify and rectify NPSH issues.

The most common symptom of a NPSH issue is cavitation, which is caused by the pump being unable to draw enough fluid to the suction port. Cavitation is characterized by a loud, high-pitched noise and a decrease in the pump’s efficiency. When cavitation occurs, the pump is no longer able to provide the necessary pressure for its operation.

To identify the source of the NPSH issue, you will need to measure the pressure at the suction port of the pump. This can be done using a pressure gauge or a vacuum gauge. If the pressure is too low, then the NPSH is inadequate.

Once the source of the NPSH issue has been identified, there are several ways to rectify the problem. One of the most common methods is to increase the pressure of the fluid at the suction port. This can be done by adding a booster pump, or by increasing the pressure of the fluid in the system. Another option is to reduce the speed of the pump, which will reduce the amount of fluid that needs to be drawn and thus reduce the pressure at the suction port.

Finally, you can also modify the design of the pump to increase the NPSH. This can be done by adding an impeller with a larger diameter, or by increasing the size of the suction port.

By properly identifying and rectifying NPSH issues, you can ensure that your pump is able to operate efficiently and effectively. While it may take some time and effort to identify and address these issues, it is important to do so in order to ensure that your pump is able to perform optimally.

NPSH and System Design

NPSH, or Net Positive Suction Head, is a critical factor in the design of any pump system. It refers to the amount of pressure that is required at the suction of the pump to maintain the desired flow rate. Without sufficient NPSH, the pump may suffer from cavitation, a phenomenon that can cause significant damage to the pump and its components.

To ensure sufficient NPSH for a given system, it is important to consider several factors. First, the size and design of the pump must be chosen to provide the desired flow rate at the given NPSH. Additionally, the location of the pump in relation to the suction source must be taken into account. For example, if the pump is located higher than the suction source, gravity will provide additional NPSH.

The system’s piping and components should also be designed to minimize pressure losses. This can be done in several ways, including using fittings or valves with a smaller diameter than the pipe, and ensuring that the pipe is properly aligned to avoid bends or twists that can cause pressure losses. Finally, the system should be checked regularly to ensure that NPSH is maintained.

By following these steps, engineers can ensure that the system has sufficient NPSH to operate safely and efficiently. With careful design and periodic maintenance, NPSH and system design can be managed to avoid cavitation and other costly problems.

Testing and Verifying NPSH Requirements

Testing and verifying NPSH levels is essential for the proper operation of a pump. NPSH stands for Net Positive Suction Head and is a measure of the pressure at the suction port of a pump. This is important to ensure that the pump is able to keep a sufficient level of pressure, even when the liquid that is being pumped is at a lower pressure than what is required to keep the pump running efficiently.

To test and verify NPSH levels, the pump must be tested at the desired flow rate for the given system. The NPSH test is conducted by measuring the pressure at the pump suction port and comparing it to the atmospheric pressure. The difference between the two is the NPSH available, which is the actual pressure the pump will experience when running. If the NPSH available is too low, the pump will not be able to maintain a sufficient pressure and will not work properly.

It is important to test the NPSH levels of a pump to ensure that it will be able to operate efficiently and safely. If the available NPSH is too low, the pump may experience cavitation and damage to its impeller. Cavitation can lead to excessive noise and vibration, increased wear, and ultimately, pump failure.

To get an accurate measure of NPSH, it is important to ensure that all measurements are taken in a consistent environment. This includes temperature, pressure, and flow rate of the pumped liquid. It is also important to ensure that the pump is not running while the NPSH test is being conducted.

By testing and verifying the NPSH levels of a pump, you can ensure that your pump is able to operate efficiently and safely. This is essential for the longevity and performance of your pump, so it is important to take the time to properly test and verify the NPSH levels of your pump.

Benefits of NPSH

NPSH, short for Net Positive Suction Head, is an important factor when it comes to assessing the performance of a pump. It is the difference between the pressure at the inlet of the pump and the vapor pressure of the fluid being pumped. A key benefit of NPSH is that it helps minimize the likelihood of cavitation in the pump, which can lead to reduced pump efficiency, vibration, and even pump failure.

NPSH plays an important role in pump performance, as it affects the flow rate of the pump and the pressure at the inlet of the pump. A higher NPSH can result in higher flow rates and higher pressures, while a lower NPSH can lead to lower flow rates and lower pressures. Furthermore, NPSH can help reduce the risk of cavitation in the pump, as it prevents vaporization of the fluid and helps keep the fluid at a high pressure.

Another important benefit of NPSH is that it can help reduce the wear and tear on the pump, as it helps reduce the likelihood of cavitation. Cavitation can lead to increased wear and tear on the pump, as it can cause vibration and other mechanical issues. By maintaining a higher NPSH, the pump is able to operate more efficiently, reducing the amount of wear and tear it experiences.

In conclusion, NPSH is an important factor when it comes to assessing the performance of a pump. By maintaining a higher NPSH, the pump is able to operate more efficiently, reducing the risk of cavitation, reducing wear and tear, and increasing flow rate and pressure. NPSH is an important factor to consider when assessing the performance of a pump and should not be overlooked.

Conclusion

In conclusion, NPSH is an important concept in pump operation. It is essential to understand and manage NPSH levels in order to ensure optimal performance from a pump. This involves understanding the concept of NPSH, calculating NPSH requirements for a given pump, calculating an appropriate NPSH margin, and testing and verifying NPSH levels. By understanding and managing NPSH levels, pump performance can be greatly improved and the benefits of NPSH realized.

Related Post: