No, a diaphragm pump does not use compressed air, it uses a flexible membrane to move the liquid.

Diaphragm pumps are an essential type of mechanical device used for pumping a variety of liquids and gases. The basic principle of a diaphragm pump is simple; a flexible diaphragm is driven by an external force, such as a motor or compressed air, to move a liquid or gas through a chamber.

This article will discuss the concept of a pneumatic diaphragm pump, an increasingly popular type of diaphragm pump. We will explore what a pneumatic diaphragm pump is, its advantages, disadvantages, and how it compares to a hydraulic diaphragm pump. We will also discuss the maintenance required for pneumatic diaphragm pumps. By the end of this article, readers will have a better understanding of the pneumatic diaphragm pump and whether it is the right choice for their needs.

What is a Pneumatic Diaphragm Pump?

To further understand how a pneumatic diaphragm pump works, it is necessary to look at the components and the mechanics of the pump.

How Does a Pneumatic Diaphragm Pump Work?

A pneumatic diaphragm pump is a type of positive displacement pump that uses compressed air as its power source. These pumps are used to transfer liquids from one place to another, and are an efficient and economical choice for many applications.

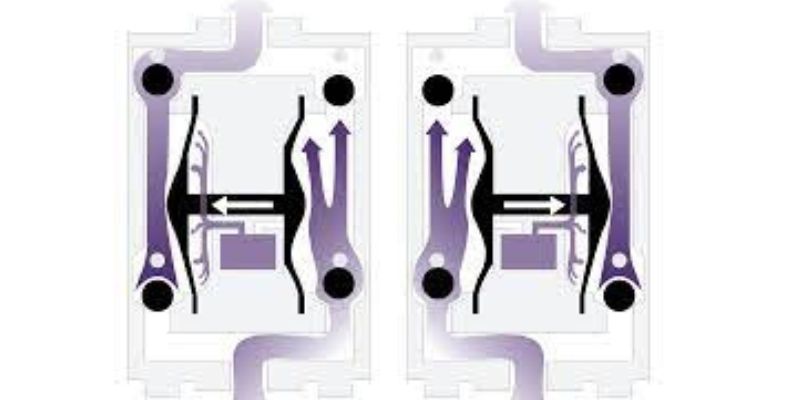

The pump consists of two chambers, which are shifted from one side to the other by a linked shaft. This allows the chambers to move in a similar way to a piston, creating a vacuum inside the chambers. The air motor then directs the air to push a diaphragm, which in turn pumps the liquid out.

Yamada Manufacturers produce air-powered double diaphragm pumps, which are a great option for those looking for an efficient and cost-effective way to move liquids. These pumps are designed to be durable and reliable, making them a great choice for many industries.

In short, a pneumatic diaphragm pump is an air-powered pump that uses compressed air to move liquids from one place to another. The air motor directs the air to push a diaphragm, which pushes the liquid out, making these pumps a great choice for efficient and economical liquid transfer.

Advantages of Pneumatic Diaphragm Pumps

Pneumatic diaphragm pumps offer a variety of advantages, including cost and efficiency.

Benefits of Using a Pneumatic Diaphragm Pump

Pneumatic diaphragm pumps offer a range of advantages over traditional pumps, making them an ideal choice for a wide range of applications. They are capable of delivering highly accurate, repeatable results over long periods of time. Here are just some of the benefits of using a pneumatic diaphragm pump:

1. Low Maintenance: Pneumatic diaphragm pumps are designed to require minimal maintenance and are virtually maintenance-free. This helps to reduce the cost of operation and ensures that the pumps are always running at their optimum.

2. High Pressure: Pneumatic diaphragm pumps can generate high pressure and can be used in applications such as chemical injection and cooling systems.

3. Low Energy Consumption: Pneumatic diaphragm pumps are highly efficient and consume less energy than traditional pumps. This means they can be used in applications where energy costs must be kept to a minimum.

4. Versatility: Pneumatic diaphragm pumps are designed to be versatile and can be used in a wide range of applications. Their modular design also means they can be adapted to fit different configurations.

5. Durability: Pneumatic diaphragm pumps are designed to be highly durable and can handle tough conditions. This ensures that your pump will provide a long-lasting, reliable performance.

In conclusion, the answer to the question “Is a diaphragm pump pneumatic?” is a resounding “yes”. Pneumatic diaphragm pumps offer a range of advantages over traditional pumps, making them an ideal choice for a wide range of applications. These benefits include low maintenance, high pressure, low energy consumption, versatility, and durability.

Cost and Efficiency

Pneumatic diaphragm pumps offer several advantages in terms of cost and efficiency. They are relatively low-cost to install, operate, and maintain, making them an ideal choice for many applications. Their efficiency is also notable, as they use only a minimal amount of energy to compress the air, resulting in significant savings.

Additionally, they are often quieter than other types of pumps, meaning they can be used in a variety of settings without disturbing nearby staff or customers. Finally, pneumatic diaphragm pumps are extremely durable and reliable, making them a great investment for any business.

Disadvantages of Pneumatic Diaphragm Pumps

While pneumatic diaphragm pumps offer a number of advantages, they also come with certain limitations and drawbacks. Let’s discuss the disadvantages of using such a pump.

Limitations of Pneumatic Diaphragm Pumps

Though pneumatic diaphragm pumps are popular for their robust design and reliability, there are certain limitations that should be taken into consideration when using them.

The main limitation of pneumatic diaphragm pumps is the size and weight of the pumps. Due to their design, they are often heavier than electric pumps and require more space to install. This can make it difficult to install them in tight spaces.

Another limitation of pneumatic diaphragm pumps is their cost. Since they require a compressor to operate, they can be quite expensive compared to electric pumps. Additionally, the cost of maintenance and repairs can be quite high.

Pneumatic diaphragm pumps also have a limited flow rate. This can be a problem if you need to move large volumes of liquid quickly. Additionally, they are not suitable for certain hazardous materials, such as flammable liquids.

Finally, pneumatic diaphragm pumps have a limited life span. They are not as durable as electric pumps and require more frequent maintenance and repair.

Though pneumatic diaphragm pumps are typically reliable, they have certain limitations that should be taken into consideration before using them. They tend to be more expensive than electric pumps, and require more space and maintenance. Additionally, their flow rate is limited and they are not suitable for certain hazardous materials.

Drawbacks of Using a Pneumatic Diaphragm Pump

When it comes to using a pneumatic diaphragm pump, there are certain drawbacks to consider. The most significant drawback is that they are not as efficient as other types of pumps, such as electric or hydraulic pumps. They also require more maintenance and can be costly to repair. Additionally, pneumatic diaphragm pumps can be loud and can create a large amount of vibration. Finally, they are not as versatile as other types of pumps and may not be able to meet the needs of all applications.

In summary, while pneumatic diaphragm pumps are relatively simple and cost-effective, they do have their drawbacks. It is important to consider these drawbacks when making the decision to use a pneumatic diaphragm pump for a particular application.

Comparison of Pneumatic and Hydraulic Diaphragm Pumps

| Feature | Pneumatic Diaphragm Pump | Hydraulic Diaphragm Pump |

|---|---|---|

| Power Source | Air Compressor | Hydraulic Fluid |

| Durability | High | Medium |

| Maintenance | Low | High |

| Cost | Low | High |

| Operating Pressure | Low | High |

| Noise Level | Low | High |

Diaphragm pumps are used in a variety of applications, and the type of pump used typically depends on the specific needs of the application. Pneumatic and hydraulic diaphragm pumps are two popular types of diaphragm pumps.

When considering which type of diaphragm pump to use, there are several key features to consider. The table above provides a comparison of pneumatic and hydraulic diaphragm pumps in terms of power source, durability, maintenance, cost, operating pressure, and noise level.

Pneumatic diaphragm pumps are powered by an air compressor and are known for their durability and low maintenance. They are also relatively inexpensive and generate lower operating pressures and noise levels than hydraulic pumps.

Hydraulic diaphragm pumps, on the other hand, are powered by hydraulic fluid and are known for their high operating pressures and noise levels. However, they require more maintenance and are more expensive than pneumatic diaphragm pumps.

Ultimately, the type of diaphragm pump that is best for any given application will depend on the specific needs of the application. Understanding the features of each type of pump can help ensure that the most suitable pump is chosen for the application.

Maintenance of Pneumatic Diaphragm Pumps

If you are looking for a reliable, low-maintenance pump, then a pneumatic diaphragm pump is a great choice. Pneumatic diaphragm pumps are powered by compressed air, and as such, require minimal maintenance. However, even the most reliable of pumps can experience wear and tear over time, and proper maintenance of a pneumatic diaphragm pump is essential for ensuring it continues to work efficiently.

To keep your pneumatic diaphragm pump working at its best, it is important to check the air pressure regularly. Make sure that the air pressure is within the recommended range. A pressure gauge can be used to check the air pressure, and if necessary, the pressure can be adjusted with a regulator.

It is also important to check the pump’s suction and discharge valves regularly. These valves should be inspected for signs of wear and tear, and replaced if necessary. Regularly cleaning these valves can help to prevent problems arising in the future.

In addition to regular maintenance checks, it is also important to check the diaphragm of the pump from time to time. This is a flexible membrane that separates the air pressure from the liquid being pumped. The diaphragm should be checked for signs of damage, and if necessary, replaced.

Finally, it is important to check for any leaks in the pneumatic diaphragm pump. This can be done by using a leak detector. If any leaks are found, it is important to repair them as soon as possible to prevent any further damage.

By following these simple steps, you can ensure that your pneumatic diaphragm pump continues to work efficiently and reliably. With regular maintenance, your pump will be able to provide efficient performance for years to come.

Conclusion

In conclusion, a diaphragm pump is indeed pneumatic. It is a pump that uses compressed air to move liquid or gas through a system. It is a reliable, cost-effective, and efficient pump that offers many advantages. However, it also has some limitations and drawbacks and therefore proper maintenance is necessary to ensure its longevity.

Related Post: