NPSH stands for Net Positive Suction Head and it is a measure of the energy available at the suction point of a pump. To calculate NPSH, we subtract the total pressure at the suction point from the vapor pressure of the liquid being pumped. This helps us determine if the pump has enough energy to lift the liquid.

Net Positive Suction Head (NPSH) is a term used to describe the pressure at the inlet of a pump. The calculation of NPSH is important for optimizing and maintaining a pump’s performance, as it is a measure of suction energy at the pump inlet, and is affected by multiple factors. In this blog post, we will explore the NPSH calculation process, and discuss the importance of adequate NPSH values in order to maximize pump performance.

Overview of the NPSH Calculation Process

The calculation of Net Positive Suction Head (NPSH) is an essential task for anyone working with pumps and fluid systems. NPSH is the amount of pressure required at the suction side of a pump to prevent cavitation. It helps to ensure that the pump is running optimally and safely. So, what is the NPSH calculation process and how can you ensure you’re getting it right?

The first step in the NPSH calculation process is to determine the static pressure at the suction side of the pump. This is usually done by measuring the fluid pressure at the suction port. The static pressure should also include any losses that occur due to elevation and friction.

The next step is to calculate the total dynamic head (TDH) of the system. This is the sum of the static pressure at the suction side of the pump, plus any additional head losses due to friction, elevation, and other factors.

From the TDH, you can then calculate the vapor pressure of the liquid in the system. This is the pressure at which the liquid starts to vaporize, and is a crucial factor in determining the NPSH.

Finally, you can calculate the NPSH by subtracting the vapor pressure from the TDH. This is the amount of pressure required at the suction side of the pump to prevent cavitation.

By following the NPSH calculation process, you can ensure that your pump is running optimally and safely. It’s important to note that the NPSH calculation process should be done regularly, as the factors that affect it can change over time. If you’re having trouble with the NPSH calculation process, don’t hesitate to contact a professional who can provide guidance and advice.

Understanding the NPSH Formula

The Net Positive Suction Head (NPSH) is a key measure of the performance of a centrifugal pump, and understanding the formula is essential for proper pump selection and maintenance. The NPSH is a measure of the amount of energy available to the pump for suction, and it is determined by the hydrostatic pressure at the pump suction and the vapor pressure of the liquid at the temperature of the liquid.

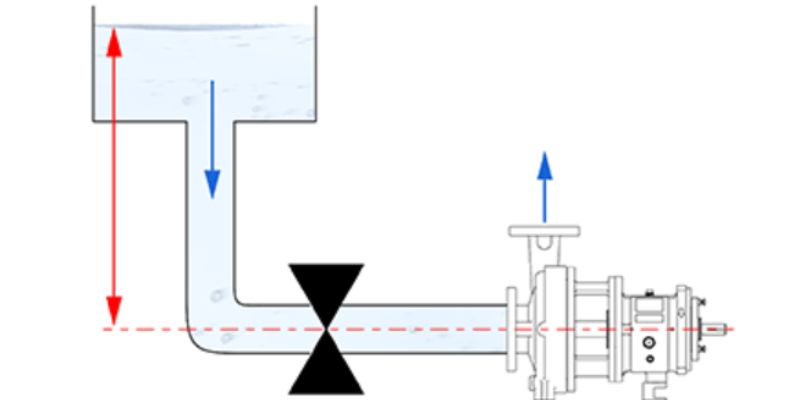

The NPSH formula is calculated by subtracting the vapor pressure of the liquid from the hydrostatic pressure of the liquid at the pump suction. The hydrostatic pressure is determined by the density of the liquid, the acceleration due to gravity, and the vertical distance between the surface of the liquid and the pump suction. The vapor pressure of the liquid is determined by the boiling point of the liquid, which can vary depending on the surrounding atmospheric pressure.

The NPSH formula is important for selecting a pump that will operate properly in a given application. Understanding the formula and its components can help determine the suction lift of the pump and the NPSH required for proper pump performance. In addition, it can help identify potential problems such as cavitation or excessive suction lift that can reduce the efficiency and life of the pump. Therefore, understanding the NPSH formula is essential for proper pump selection and maintenance.

Factors Affecting NPSH Calculations

NPSH (Net Positive Suction Head) is an important concept to consider when designing and operating a pumping system. It is a measure of the pressure that is available at the suction side of a pump to prevent cavitation. Cavitation can cause damage to the pump and reduce its efficiency, so it is important to know the NPSH of a given system.

When calculating the NPSH of a system, several factors must be taken into account. These include the elevation of the pump, the suction pressure, the water temperature, the viscosity of the fluid, the vapor pressure of the fluid, and the flow rate.

The elevation of the pump affects the NPSH calculation because the higher the elevation, the lower the pressure at the suction side of the pump. The suction pressure is the pressure of the fluid at the suction side of the pump, while the water temperature affects the vapor pressure of the fluid. The viscosity of the fluid affects the flow rate, and the vapor pressure of the fluid affects the amount of vacuum that can be created at the suction side of the pump.

It is important to consider these factors when calculating the NPSH of a system, as they can have a significant impact on the performance of the pump. If the NPSH is too low, cavitation can occur, leading to damage to the pump. On the other hand, if the NPSH is too high, the pump may become inefficient.

By taking into account all of these factors, it is possible to get an accurate calculation of the NPSH of a system. This will ensure that the pump is operating safely and efficiently, and that cavitation is avoided.

Importance of Adequate NPSH Values

A Net Positive Suction Head (NPSH) value is an important consideration in pumping systems, as it determines the available pressure at the pump’s suction port. It is the amount of pressure, in feet or metres, that is above the vapor pressure of the liquid being pumped. In order for the pump to operate properly and without cavitation, it must have an adequate NPSH value.

The importance of an adequate NPSH value lies in the fact that it must be greater than the NPSH required of the pump. The NPSH required is the amount of pressure needed for the pump to operate without cavitation, which is the formation of vapour bubbles due to a lack of pressure. Cavitation can cause damage to the pump, which can lead to costly repairs or replacements.

In order to calculate the NPSH of a system, the pressure of the incoming liquid must first be determined. Then, the total dynamic head of the system must be calculated, which includes the friction head and the static head. Finally, the NPSH of the system can be calculated by subtracting the total dynamic head from the pressure of the incoming liquid.

Having an adequate NPSH value is essential for a pump’s performance and longevity. Without it, the pump may be prone to cavitation, which can cause permanent damage to the pump. Furthermore, inadequate NPSH values can lead to reduced efficiency, as the pump has to work harder to draw the liquid from the source. Therefore, it is important to ensure that the NPSH of the system is greater than the NPSH required of the pump.

Calculation of NPSH Values

NPSH stands for Net Positive Suction Head, which is a measure of how much pressure a pump must have at its suction port in order to prevent cavitation. The calculation of NPSH values is essential for proper functioning of pumps, as cavitation can cause serious damage to the pump and its components.

The calculation of NPSH values requires a few key pieces of information, including the atmospheric pressure (P1), the vapor pressure of the liquid (P2), the elevation of the pump above the liquid level (H1), and the acceleration head (H2). These values are then combined using the following formula: NPSH = P1 + P2 – H1 + H2.

The atmospheric pressure (P1) is the pressure of the air around the pump. This is usually measured in inches of mercury (inHg) and can be found on the local weather report. The vapor pressure of the liquid (P2) is the pressure of the vapor at the pump’s suction port and is usually measured in pounds per square inch (psi). The elevation of the pump above the liquid level (H1) is the vertical distance between the pump and the liquid. This is usually measured in feet and can be found with a tape measure. Finally, the acceleration head (H2) is the pressure created by the acceleration of the liquid as it enters the pump, and is usually measured in feet of liquid.

Once these four values have been calculated, the NPSH value can be derived using the formula above. A higher NPSH value indicates that the pump is better able to prevent cavitation and is therefore more efficient. It is important to note that the NPSH values must be re-calculated if any of the four original parameters change.

Calculating NPSH values is an essential part of the pump selection process. By understanding the principles of NPSH and the formula for calculating it, engineers and technicians can ensure that their pumps are running optimally and are not at risk of damage due to cavitation.

Identifying the Sources of System Pressure Loss

Identifying the sources of system pressure loss is an important part of maintaining the overall health and efficiency of any hydraulic system. Pressure loss can be caused by a variety of factors, including flow restriction, air entrapment, and incorrect pipe sizing. When it comes to calculating the amount of pressure loss, one of the most important parameters to consider is the Net Positive Suction Head (NPSH).

NPSH is a measure of the pressure available at the suction side of the pump, relative to the vapor pressure of the fluid being pumped. The higher the NPSH value, the greater the pressure available, and the less likely it is that cavitation will occur. To calculate NPSH, the total pressure head at the suction inlet must be known, as well as the vapor pressure of the fluid being pumped. The formula for NPSH is:

NPSH = Total Pressure Head at Suction Inlet – Vapor Pressure of Fluid being Pumped

It is important to note that the vapor pressure of the fluid being pumped depends on its temperature. To ensure accuracy, the temperature of the fluid should be taken into account when calculating NPSH. Once NPSH is calculated, it can be compared to the NPSH required by the pump. If the NPSH available is lower than the NPSH required, cavitation could occur.

By understanding the sources of system pressure loss, and accurately calculating NPSH, hydraulic system operators can ensure the system is operating efficiently, and minimize the risk of cavitation.

Understanding the Impact of NPSH on Pump Performance

Understanding the impact of NPSH on pump performance is an important part of properly operating a pump. NPSH, or Net Positive Suction Head, is a measure of the pressure that is available for the pump to draw liquid from its suction source. Having an adequate NPSH is critical for achieving optimal pump performance.

The NPSH calculation is determined by subtracting the absolute pressure of the liquid at the pump’s suction port from the vapor pressure of the liquid at the same temperature and elevation as the pump’s suction port. The result of this calculation is expressed in feet of liquid head.

For example, if the absolute pressure of the liquid at the pump’s suction port is 0.5 psi and the vapor pressure of the liquid at the same temperature and elevation is 0.2 psi, then the NPSH is equal to 0.3 psi (0.5 – 0.2 = 0.3). This 0.3 psi of NPSH is equal to 2.3 feet of liquid head.

If the NPSH is too low, then the pump will not be able to draw liquid from its suction source. This can lead to cavitation, which is a condition in which air bubbles form in the liquid and cause damage to the pump’s impeller. To ensure that the pump is operating at its peak performance, it is important to calculate the NPSH and make sure it is adequate for the pump’s design.

In conclusion, understanding the impact of NPSH on pump performance is essential for proper pump operation. Calculating the NPSH is the best way to ensure that the pump is able to draw liquid from its suction source and that it is able to operate at its peak performance.

Troubleshooting Low NPSH Problems

Troubleshooting low NPSH problems can be a challenging task, especially if you don’t understand the basics of how NPSH is calculated. NPSH stands for Net Positive Suction Head and is an important value in the operation of any centrifugal pump. It is the amount of pressure required to prevent cavitation from occurring in the pump. In other words, it is the difference between the total suction head and the vapor pressure of the liquid in the suction line.

To ensure that a centrifugal pump operates optimally, it is important to maintain an adequate NPSH value. If the NPSH is too low, the pump will not be able to draw sufficient fluid from the pump inlet and will run inefficiently. As such, it is important to understand how to calculate NPSH and detect any potential problems.

NPSH can be calculated by subtracting the vapour pressure of the liquid being pumped from the total suction head. The total suction head is the sum of the static suction head, the velocity head and the friction loss head in the suction line. The vapour pressure of the liquid is dependent on the temperature of the liquid, so it is important to accurately measure the temperature of the liquid when calculating NPSH.

In the event of a low NPSH value, the first step is to check whether the suction pressure is at a level that is below the vapour pressure of the liquid. If this is the case, then the problem is likely to be related to the temperature of the liquid. Reducing the temperature of the liquid can help to increase the NPSH value. If the temperature is not the issue, then the problem may be due to the suction head being too low. In this case, reducing the friction losses in the suction line can help to increase the NPSH value.

Ultimately, troubleshooting low NPSH problems requires a thorough understanding of the basics of NPSH calculation. By understanding the total suction head and vapour pressure of the liquid, it is possible to detect any problems and take the necessary steps to restore optimal performance.

Calculating the NPSH Requirements of a Specific Pump

Calculating the NPSH requirements of a specific pump is an important step in ensuring its efficiency and performance. NPSH stands for Net Positive Suction Head and is a measure of the available energy level of the fluid at the inlet of the pump, which determines the amount of suction lift that the pump can achieve. The NPSH requirements of a pump depend on a number of factors, including the type of pump, the inlet pressure of the fluid, the temperature of the fluid, and the viscosity of the fluid.

In order to accurately calculate the NPSH requirements of a specific pump, the following steps should be taken:

1. Estimate the suction lift that the pump will be required to achieve, based on the pressure of the fluid at the pump inlet.

2. Calculate the total head of the pump inlet, which is the sum of the inlet pressure and the suction lift.

3. Calculate the vapor pressure of the fluid at the pump inlet, based on its temperature.

4. Calculate the total dynamic head (TDH) of the pump, which is the sum of the total head of the pump inlet and the vapor pressure of the fluid.

5. Calculate the NPSH available (NPSHa) at the pump inlet, which is the total dynamic head of the pump minus the vapor pressure of the fluid.

6. Calculate the NPSH required (NPSHr) of the pump, based on the type of pump, the viscosity of the fluid, and the speed of the pump.

Once the NPSH available and required have been calculated, the efficiency and performance of the pump can be determined. If the NPSH available is greater than the NPSH required, then the pump should be able to operate as expected. If not, then the pump should be adjusted or replaced in order to ensure its efficiency and performance.

Optimizing NPSH Values for Maximum Pump Performance

NPSH, or Net Positive Suction Head, is a critical factor in the performance of any pump. It’s the amount of pressure that must be present in the liquid in the suction pipe of a pump in order to avoid cavitation. When the NPSH is low, the pump is at risk of cavitation, which can cause damage to the pump and reduce performance.

So, how do you determine the NPSH value of your pump? The first step is to calculate the liquid’s absolute pressure in the suction pipe. This can be done by measuring the static pressure at the suction side of the pump and subtracting the vapor pressure of the liquid. The result is the absolute pressure of the liquid.

Once you have the absolute pressure, you can calculate the NPSH value. This is done by subtracting the vapor pressure of the liquid from the absolute pressure of the liquid. The result is the NPSH value.

When it comes to optimizing NPSH values for maximum pump performance, the key is to ensure that the NPSH value is high enough to avoid cavitation. If the NPSH value is too low, it can lead to cavitation, which can cause damage to the pump and reduce performance.

It’s important to keep in mind that the NPSH value is affected by several factors, including the suction pipe size, the liquid temperature, and the static pressure in the suction pipe. To ensure that the NPSH value is high enough to avoid cavitation, it’s important to consider these factors and make any necessary adjustments.

By taking the time to calculate and optimize the NPSH value of your pump, you can ensure maximum pump performance and avoid costly damage due to cavitation.

Conclusion

In conclusion, calculating NPSH is an important part of maintaining pump performance and safety. It requires understanding of the NPSH formula, factors that affect NPSH calculations, and sources of system pressure loss. It’s also important to understand the impact of NPSH on pump performance, and how to identify and troubleshoot low NPSH problems. Lastly, calculating the NPSH requirements of specific pumps, and optimizing NPSH values for maximum pump performance, will ensure optimal performance and safety.

Related Post: