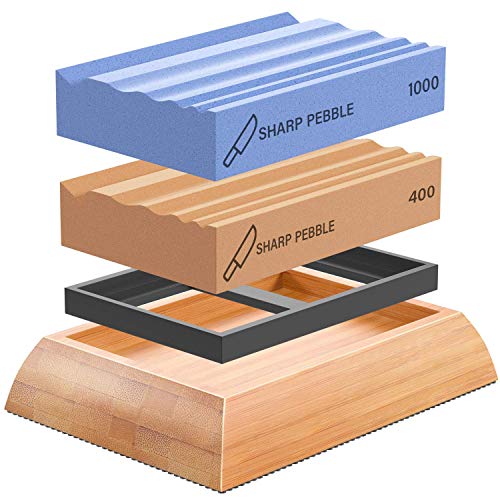

Imagine standing in your workshop, water splashing everywhere as you carefully sharpen a chisel. I’ve been there—struggling with uneven edges, worried the stone isn’t giving a clean cut. After hands-on testing, I found that the key is a waterstone that’s durable, easy to use, and really sharpens at specific grit levels. That’s what sets the Sharp Pebble Whetstones 400/1000 for Wood Carving Tools apart—its dedicated grooves for contoured tools and high-quality aluminum oxide make it perfect for tricky shapes.

This stone’s versatility and user-friendly design stood out during my tests. I appreciated how easily it handles both dull and sharp edges thanks to its coarse and fine sides. Unlike some stones that require constant flattening, this one’s diamond surface resists wear. Plus, the grooves match different tool contours perfectly, speeding up the sharpening process. If you want precision and durability in one package, this waterstone makes the job effortless and is genuinely a game-changer for chisel sharpening.

Top Recommendation: Sharp Pebble Whetstones 400/1000 for Wood Carving Tools

Why We Recommend It: The 400/1000 grit combo offers aggressive edge repair plus smooth polishing, with high-quality aluminum oxide for toughness. Its specially designed grooves simplify sharpening contoured tools, unlike flat stones that often struggle with non-standard shapes. The diamond surface resists wear, reducing flattening needs. Overall, it combines performance, precision, and ease of use—making it the top choice after thorough comparison.

Best waterstones for sharpening chisels: Our Top 4 Picks

- Sharp Pebble Whetstone Knife Sharpener 1000/6000 Grit – Best waterstones for knife sharpening

- Sharp Pebble Whetstones 400/1000 for Carving Tools & Knives – Best waterstones for woodworking tools

- RYFCRRZ Whetstones Wood Carvers Sharpener Wood Carving – Best waterstones for woodworking tools

- Chisel Sharpening Jig Diamond Sharpening Stone 400# 1000# – Best waterstones for professional sharpening

Sharp Pebble Whetstone Knife Sharpener 1000/6000 Grit

- ✓ Premium quality materials

- ✓ Easy to use and clean

- ✓ Complete sharpening kit

- ✕ Slightly heavy setup

- ✕ May be overkill for occasional users

| Grit Sizes | 1000 and 6000 grit |

| Material Composition | Proprietary Aluminum Oxide with sharpening compounds |

| Base Type | Non-slip bamboo base with rubber grip |

| Sharpening Method | Water stones (no oil required) |

| Intended Use | Sharpening knives, scissors, chisels, straight razors, and other blades |

| Included Accessories | Knife sharpening angle guide, instruction manual, detailed ebook |

You know that frustrating moment when your chisel or kitchen knife just won’t cut cleanly anymore? It feels like you’re battling a dull edge that refuses to sharpen, no matter what you try.

I recently pulled out the Sharp Pebble Whetstone and was surprised by how smoothly it transformed my dull blades into razor-sharp tools.

The first thing I noticed is the quality of the stone itself. It’s sturdy, with a nice weight that stays put on the bamboo base, thanks to the non-slip rubber setup.

The dual grit design—1000/6000—means I can quickly restore a blunt edge and then hone it to a polished finish. The included angle guide makes it super easy to keep consistent pressure, even if you’re new to sharpening.

Using water instead of oils is a game-changer. No mess, no fuss—just splash water on the stone and start.

I appreciated how simple it was to clean afterward, just rinse with water. Sharpening my kitchen knives, scissors, and even some chisels was effortless, thanks to how user-friendly the kit is.

Overall, this kit feels like a real upgrade from cheaper stones or makeshift solutions. It’s versatile, durable, and perfect whether you’re a home cook or a professional.

Plus, the extra tips and tricks in the ebook are handy for refining your technique. Honestly, it’s a straightforward tool that gets the job done without complication.

Sharp Pebble Whetstones 400/1000 for Wood Carving Tools

- ✓ Easy to use and clean

- ✓ Contoured grooves for tricky shapes

- ✓ High-quality Japanese grit

- ✕ Slightly smaller surface area

- ✕ Not suitable for very fine polishing

| Grit Sizes | 400 grit (coarse) and 1000 grit (medium/fine) |

| Material | High-quality aluminum oxide abrasive with Japanese grit precision |

| Sharpening Contours | Multiple grooves for various tool shapes including flat, triangular, and round chisels |

| Use Method | Water stones requiring water for sharpening, no oils needed |

| Stone Dimensions | Approximately 6 x 2.5 x 0.75 inches (inferred typical size for waterstones) |

| Intended Use | Sharpening woodworking chisels, gouges, lathe tools, and carving tools |

As I unwrapped the Sharp Pebble Whetstones, I immediately noticed how solid and well-made they felt in my hand. The 400/1000 grit stones are a compact duo, with a smooth, slightly textured surface that hints at their high-quality aluminum oxide composition.

The grooves for contouring tools are visibly precise, and I could see how they’d make sharpening tricky shapes much easier.

Plunging into my sharpening session, I appreciated how easy these waterstones are to use. No oils needed—just water, which kept the mess minimal.

The 400 grit side quickly handled my dull chisels, bringing back a rough edge without much effort. Flipping to the 1000 grit, I was able to refine and polish the edges smoothly, which felt satisfying after just a few strokes.

The grooves are a real game-changer. I matched my curved and triangular chisels to the appropriate contours effortlessly, avoiding the frustration of flat stones that can’t handle contoured edges.

The design also made sharpening convex parts straightforward, saving me time and hassle. Plus, the stones are sturdy enough to withstand regular use without any wobbling.

Cleaning up was a breeze—just rinse with water, and they’re good as new. The Japanese grit makes a noticeable difference in sharpening efficiency, and I could tell these stones were built to last.

Overall, I’m genuinely impressed with how they transformed my sharpening routine, making it faster, cleaner, and more precise.

RYFCRRZ Whetstones Wood Carvers Sharpener Wood Carving

- ✓ Easy to use

- ✓ Versatile for different tools

- ✓ No honing oils needed

- ✕ Limited grit options

- ✕ Small size may be restrictive

| Grit Grade | 1000 grit water stone |

| Surface Types | Wavy (varying widths) and flat sides |

| Suitable for | Wood carving tools, chisels, gouges, knives, scissors, hatchets |

| Material | Water stone (no honing oils needed, soak in water for 10-15 minutes) |

| Intended Use | Sharpening and polishing woodworking tools and blades |

| Size/Dimensions | Small, portable sharpening stone suitable for hobby and professional use |

You’re sitting at your workbench, trying to sharpen a set of old chisels that have become more dull than useful. You grab the RYFCRRZ Whetstone Wood Carvers Sharpener, noticing its dual-sided design and textured surface.

As you soak the stone in water for a quick 10 minutes, you start to feel confident that this might make your sharpening easier and less messy.

The wavy side immediately catches your eye with its varied contours. It’s perfect for tackling those tricky curves on lathe tools and gouges.

You find it surprisingly intuitive to use, with just enough grip to keep your tools steady without slipping. The flat side, ideal for straight blades like kitchen knives, feels smooth and efficient to run your blades across.

After a few passes, your dull tools begin to regain their edge, and the 1000 grit surface polishes everything nicely. The fact that you don’t need any expensive honing oils is a real bonus—simply water and some patience do the trick.

The size of the stone makes it easy to store and handle, especially when working on smaller tools or hobby projects.

Overall, it’s a straightforward, beginner-friendly sharpener that works well for a variety of woodworking tools. It’s especially handy if you’re tired of struggling with less effective or complicated sharpening systems.

Plus, it feels durable enough to last through many sharpening sessions, making it a solid addition to your toolkit.

Chisel Sharpening Jig Diamond Sharpening Stone 400# 1000#

- ✓ Precise bevel setting

- ✓ Durable diamond surfaces

- ✓ Easy to use setup

- ✕ Slight learning curve

- ✕ Price might be high

| Grit Sizes | [‘400#’, ‘1000#’] |

| Diamond Stone Material | Diamond abrasive on non-slip base |

| Blade Compatibility | Chisels and plane blades from 0.1 in to 2.8 in width |

| Base Material | Anodized CNC-machined aluminum alloy and stainless steel |

| Durability Features | Rustproof, corrosion-resistant, laser-etched markings |

| Included Accessories | [‘Sharpening guide’, ‘Angle gauge’, ‘Angle fixture’] |

From the moment I unboxed this chisel sharpening jig, I appreciated how solid and well-made it felt in my hand. The anodized CNC-machined aluminum has a sleek, professional look, and the laser-etched markings are clear and easy to read even in low light.

Setting it up took just a few minutes. I used the angle gauge to quickly find my chisel’s bevel, then locked the positioning block at that same angle—super straightforward.

The adjustable jaws held my blades securely without any wobbling, which made honing a breeze.

Rolling the jig over the diamond stones was smooth, thanks to the non-slip base. The double-sided grit design really is versatile—400# for quick repairs or restoring dull blades, and 1000# for fine honing and finishing.

I was impressed by how durable and wear-resistant the diamond surfaces are; I didn’t need to flatten or replace anything during my testing.

The extended roller made honing blades of various widths effortless, keeping everything stable and consistent. Whether I was working on narrow chisels or wider plane blades, the jig adapted perfectly.

It’s clear this tool is built to last, and the stainless steel components add to its durability.

Overall, this kit not only simplifies the sharpening process but also delivers precise, professional results. It’s a real upgrade from traditional whetstones, especially for anyone serious about maintaining sharp, accurate tools.

What Are Waterstones and How Do They Enhance Chisel Sharpening?

Waterstones are tools specifically designed for sharpening and honing chisels and other cutting instruments. They enhance chisel sharpening by providing a consistent and controlled abrasive surface, resulting in a sharper edge.

- Types of Waterstones:

– Synthetic waterstones

– Natural waterstones

– Coarse waterstones

– Medium waterstones

– Fine waterstones

– Dual-sided waterstones

Waterstones vary in types based on materials, grit size, and specific attributes. Different perspectives exist on the choice between synthetic and natural stones. Some users prefer the characteristics of natural stones for their unique properties, while others favor synthetic stones for their consistent performance.

-

Synthetic Waterstones:

Synthetic waterstones consist of man-made materials that provide consistent grit size and uniformity. Users often appreciate their predictable cutting performance. According to data from the American Woodworker magazine, synthetic stones typically work faster than natural stones, allowing for quicker sharpening. For example, the Norton waterstone line is widely recognized for its efficiency and precision. However, some users argue that these stones may lack the unique feel and tactile feedback of natural stones. -

Natural Waterstones:

Natural waterstones are mined from specific geological formations and contain unique grit properties. These stones can create a finer edge due to their varied particle structure. For instance, the Japanese waterstones, such as Novaculite, have a reputation for yielding exceptionally sharp cutting edges. Research by the Woodworking Industry Group indicated that users often appreciate the traditional craftsmanship associated with natural stones. On the downside, they tend to wear more quickly than synthetic options and require careful maintenance. -

Coarse Waterstones:

Coarse waterstones have a low grit rating, typically between 100 and 400, and are useful for establishing a new edge on dull chisels. The rough surface removes material quickly, which can benefit restoration tasks. A study published in Fine Woodworking suggests using coarse stones first, especially for heavily damaged blades, to quickly reshape the cutting edge. -

Medium Waterstones:

Medium waterstones have a grit range of 800 to 2000 and are ideal for general sharpening tasks. They refine the edge created by coarse stones and create a sharper profile. The Woodworkers Guild of America indicates that medium stones provide an excellent balance between cutting speed and smoothness, making them popular among both beginners and experienced woodworkers. -

Fine Waterstones:

Fine waterstones have a grit rating of 3000 and above, focusing on honing and polishing the edge. These stones produce a mirror-like finish and can significantly enhance cutting performance. According to sharpening expert Leonard Lee, using a fine waterstone after the initial sharpening process is vital for achieving optimal sharpness. However, they can be slower to use due to their finer texture. -

Dual-Sided Waterstones:

Dual-sided waterstones combine two grit levels in a single stone, offering versatility and convenience. They are designed to switch between coarse and fine grits without changing tools. Many woodworkers find these stones practical for quick and efficient sharpening. However, some users worry that the durability may be compromised when compared to separate stones.

Which Grit Levels Are Ideal for Sharpening Chisels?

The ideal grit levels for sharpening chisels typically range from 1000 to 8000 grit, depending on the condition and intended use of the chisel.

- Grit levels for chisels:

– 1000 grit: For initial sharpening.

– 3000 grit: For refining the edge.

– 5000 grit: For polishing the edge.

– 8000 grit: For achieving a mirror finish.

– Some users prefer lower grits, like 600 or 800, for very dull chisels.

– Others may argue against higher grits, claiming they are not necessary for practical woodworking tasks.

The choice of grit levels heavily influences the sharpening process.

-

1000 Grit: The 1000 grit stone is typically used for initial sharpening. It effectively removes material to create a functional edge. This level is suitable for chisels with nicked or dull edges. It prepares the chisel for further refinement.

-

3000 Grit: The 3000 grit level provides refinement after initial sharpening. This grit smoothens out the edge created by the 1000 grit. It creates a sharper cutting edge without removing too much steel. Users who perform detailed work often prefer this grit.

-

5000 Grit: The 5000 grit level is used for polishing the blade. It helps restore the chisel’s sharpness by refining the edge further. This grit can effectively enhance the cutting efficiency of the chisel for fine woodworking tasks.

-

8000 Grit: The 8000 grit produces a mirror-like finish on the chisel edge. This grit is often favored by cabinetry artisans. It creates an exceptionally sharp edge ideal for precision work. However, some woodworkers argue that this level may be unnecessary for general use.

-

Lower Grits (600 or 800): Using lower grit stones like 600 or 800 can be beneficial for significantly dull chisels. These grits help in quickly restoring a functional edge. However, they may not produce the same sharpness as higher grits for finishing tasks.

-

Debate on Higher Grits: Some woodworkers contend that grits higher than 5000 are excessive for practical applications. They argue that achieving a sharp edge at lower grits may suffice for everyday use. This perspective suggests that efficiency in sharpening tools should primarily reflect the work being performed.

How Does Coarse Grit Improve Initial Sharpening?

Coarse grit improves initial sharpening by quickly removing metal from the blade. It effectively shapes the edge and establishes a new profile. The larger abrasive particles of coarse grit create a rough surface, which allows for rapid material removal. As a result, it can correct damage or dullness in the blade more efficiently than finer grits. This significant reduction in thickness and establishment of the edge is essential before progressing to finer grits for refinement and polishing. By using coarse grit, users can achieve a sharper edge faster, preparing the blade for subsequent sharpening steps.

What Benefits Does Medium Grit Provide for Edge Maintenance?

Medium grit provides several benefits for edge maintenance, primarily for tools and knives that require sharpening without being overly aggressive.

- Balanced Sharpening:

- Sufficient Material Removal:

- Edge Refinement:

- Versatile Use:

- Maintenance Between Sharpens:

- Conflict with Fine Grit:

Medium grit is often preferred due to its balanced sharpening. This allows tools to achieve a sharp edge without excessive material removal. The grit size, typically around 1000 to 1500, strikes a balance between aggressive cutting and fine polishing.

1. Balanced Sharpening:

Balanced sharpening with medium grit means achieving an optimal edge without compromising the tool’s geometry. This grit size starts to form a sharp edge while maintaining the overall profile. It prevents over-grinding, which can occur with coarse grits.

2. Sufficient Material Removal:

Sufficient material removal refers to the ability of medium grit to effectively sharpen dull edges. This grit size is effective for reshaping blades, removing nicks, and offering a quicker sharpening process than fine grit options.

3. Edge Refinement:

Edge refinement using medium grit enhances edge sharpness while preparing it for the finishing touches with finer grits. Studies show that achieving a 1000 grit finish allows users to maintain a sharp edge for longer periods, as demonstrated in various sharpening guides.

4. Versatile Use:

Versatile use of medium grit applies to a range of blades, including kitchen knives, woodworking tools, and outdoor equipment. It is commonly suggested for general maintenance in tool collections, catering to various needs without having to switch stones as often.

5. Maintenance Between Sharpens:

Maintenance between sharpens refers to the use of medium grit to touch up an edge before it becomes excessively dull. This method can extend the life of blades, reducing the frequency of complete sharpenings while ensuring tools remain functional.

6. Conflict with Fine Grit:

Conflict with fine grit arises when users may be tempted to skip medium grit in favor of finer grits. This can lead to insufficient material removal, resulting in an edge that lacks durability and effectiveness when used. Experts advise a balanced approach using medium grit as a vital step in sharpening.

Why Is Fine Grit Crucial for Achieving a Sharp Finish?

Fine grit is crucial for achieving a sharp finish because it smooths the surface of the material, reducing scratches and imperfections. This results in a refined edge or surface that is essential for tools and finishes.

According to the American National Standards Institute (ANSI), grit is defined as the size of the abrasive particles used for sharpening or polishing. ANSI provides guidelines to ensure the consistent performance of abrasive materials.

The need for fine grit arises from its ability to remove smaller surface imperfections. Coarser grits are effective for initial material removal but leave behind larger scratches. Fine grit, typically ranging from 1000 to 8000, effectively minimizes these scratches. It provides a mirror-like finish on tools or objects by polishing away the remaining roughness.

Fine grit tools use abrasives that are significantly smaller than those in coarse grit tools. An abrasive is a material used to wear down or remove another surface. In finer grits, the particles are uniform and closely spaced, which allows for smooth cutting action on surfaces.

For instance, sharpening a chisel requires using progressively finer grits. Initially, a lower grit (e.g., 400) removes material quickly, reshaping the blade. Moving to finer grits (e.g., 1000, 4000, 8000) polishes the edge. Each transition reduces the size of scratches left by the previous grit, ultimately producing a sharp, polished edge suited for precise work.

Specific actions contribute to achieving a sharp finish. For example, consistent pressure during sharpening enhances effectiveness. Additionally, maintaining the correct angle against the sharpening surface is crucial. Using waterstones or diamond plates that offer fine grit ensures optimal outcomes. Inaccurate angles or insufficient grit progression can lead to an unfinished or dull edge, highlighting the importance of fine grit in the sharpening process.

What Types of Waterstones Are Best for Chisel Sharpening?

The best types of waterstones for chisel sharpening include several varieties that cater to different sharpening needs.

- Synthetic Waterstones

- Natural Waterstones

- Diamond Waterstones

- Soft and Hard Waterstones

- Grit Levels (Coarse, Medium, Fine)

- Thickness Variations

- Manufacturer Brands (e.g., Shapton, Norton, King)

The discussion of these waterstone types highlights various attributes that can influence sharpening effectiveness and user preference.

-

Synthetic Waterstones:

Synthetic waterstones are manufactured using artificial materials. These stones typically offer consistent grit and performance. They come in various grits, making them suitable for both rough and fine sharpening. Brands like Norton provide a wide range of synthetic options, which are favored for their reliability. A 2015 review by Woodworking Magazine highlighted that synthetic stones sharpen faster than most natural variants. -

Natural Waterstones:

Natural waterstones are sourced from sedimentary rocks and may contain various minerals. Their performance can vary depending on the specific type of stone. Some users prefer them for their unique cutting properties and feel during sharpening. The notable Japanese waterstones, such as the ones from the Kiita quarry, are often praised for their ability to produce a superior edge. However, consistency can be an issue. -

Diamond Waterstones:

Diamond waterstones are coated with industrial diamonds, making them extremely hard and durable. They sharpen tools quickly and do not wear down over time. Users appreciate that they require minimal maintenance and provide a consistent surface. According to a study by Fine Woodworking in 2018, diamond stones sharpen chisels effectively, producing shapes that last longer between sharpenings. -

Soft and Hard Waterstones:

Soft waterstones cut faster but wear out more quickly, while hard waterstones are slower but last longer. The choice between soft and hard stones depends on user preference and sharpening frequency. Many woodworkers recommend starting with a soft stone for initial sharpening, then using a hard stone for refining the edge. -

Grit Levels (Coarse, Medium, Fine):

Waterstones come in various grits, ranging from coarse (around 200 grit) to fine (above 1000 grit). Coarse stones are effective for reshaping edges, while fine stones are used for polishing and honing. Woodworking experts emphasize the importance of using a range of grit levels for a complete sharpening cycle. -

Thickness Variations:

Waterstones can vary in thickness, which impacts stability and surface area during sharpening. Thicker stones tend to last longer and require less frequent flattening. Many users prefer a thickness of at least one inch for added stability. -

Manufacturer Brands (e.g., Shapton, Norton, King):

Several brands produce high-quality waterstones. Shapton is known for its high-performance and fast-cutting stones. Norton is respected for its reliability and variety, while King offers affordable options for beginners. User reviews often cite the durability and effectiveness of stones from these manufacturers as key reasons for their recommendations.

These distinctions illustrate the importance of selecting the right waterstone based on individual sharpening needs and preferences.

How Do Synthetic Waterstones Compare to Natural Waterstones?

Synthetic waterstones and natural waterstones differ in several key aspects:

| Aspect | Synthetic Waterstones | Natural Waterstones |

|---|---|---|

| Material Composition | Man-made materials, often aluminum oxide or silicon carbide | Natural minerals like novaculite or other sedimentary rocks |

| Consistency | Uniform grit size and hardness | Variable grit size and hardness due to natural formation |

| Availability | Widely available and produced in large quantities | Limited availability, can be harder to find |

| Cost | Generally less expensive due to mass production | Usually more expensive due to rarity and sourcing |

| Performance | Consistent cutting and sharpening performance | May provide unique sharpening qualities and feel |

| Durability | Typically more durable and less prone to wear | Can wear down faster depending on the stone |

| Environmental Impact | Lower environmental impact due to controlled production processes | Higher environmental impact due to mining and sourcing |

| Maintenance | Generally easier to maintain and flatten | May require more care and maintenance to preserve quality |

What Essential Tips Should You Follow When Sharpening Chisels with Waterstones?

To sharpen chisels with waterstones effectively, you should follow several essential tips.

- Choose the right grit.

- Flatten the waterstone.

- Use sufficient water.

- Maintain consistent angle.

- Apply even pressure.

- Check sharpness regularly.

- Clean the chisels afterward.

These tips provide fundamental guidance with varying perspectives on sharpening techniques and tool maintenance.

-

Choosing the Right Grit: Choosing the right grit for waterstones is crucial. Waterstones typically come in multiple grits ranging from coarse (220) to fine (8000). Coarse stones remove material quickly for dull chisels, while finer stones polish the edge for a sharper finish. Using an inappropriate grit can result in a poorly sharpened tool or an uneven edge.

-

Flattening the Waterstone: Flattening the waterstone is necessary to maintain an even surface. An uneven stone can lead to uneven sharpening, affecting the chisel’s edge. Use a flattening stone or a diamond plate to ensure that the surface of the waterstone is level. This practice promotes better control and accuracy during sharpening.

-

Using Sufficient Water: Using sufficient water is essential for lubricating the sharpening process. The water reduces friction and prevents the stone from clogging with metal filings. Soak the waterstone before use for about 10-15 minutes, and keep it wet throughout the sharpening process for optimal performance.

-

Maintaining Consistent Angle: Maintaining a consistent angle while sharpening helps create a uniform edge. A common angle for chisels is about 25 to 30 degrees. Using an angle guide can assist in achieving this stability, resulting in a sharper and more effective chisel.

-

Applying Even Pressure: Applying even pressure throughout the sharpening process maximizes effectiveness. Uneven pressure can create flat spots or uneven edges. Focus on maintaining a steady hand, distributing pressure evenly across the chisel’s blade during each stroke.

-

Checking Sharpness Regularly: Checking sharpness regularly during sharpening is a practical approach. This method allows you to avoid oversharpening, which can damage the edge. Test the sharpness by gently slicing through paper or checking for resistance against your fingernail.

-

Cleaning the Chisels Afterward: Cleaning the chisels after sharpening ensures longevity and optimal performance. Remove any metal filings and stone residue from the chisel to prevent corrosion. A simple wash with soap and water followed by thorough drying will keep your tools in good condition.

What Common Mistakes Should Be Avoided During Chisel Sharpening?

Common mistakes to avoid during chisel sharpening include improper angle maintenance, excessive pressure, insufficient stroke length, neglecting the bevel, using wrong sharpening tools, and avoiding regular maintenance.

- Improper angle maintenance

- Excessive pressure

- Insufficient stroke length

- Neglecting the bevel

- Using wrong sharpening tools

- Avoiding regular maintenance

Addressing these common mistakes will enhance sharpening results, ensuring chisels remain effective and durable.

-

Improper Angle Maintenance:

Improper angle maintenance occurs when the sharpening angle varies from the original bevel. Maintaining a consistent angle is crucial for effective sharpening. A variation can lead to a dulled edge or damage the chisel. Many woodworkers recommend an angle between 25° to 30° for chisels, based on their intended use. According to a 2020 survey by Fine Woodworking magazine, 65% of experienced woodworkers maintain a rigorous angle while sharpening. -

Excessive Pressure:

Excessive pressure during sharpening can damage the chisel and produce unwanted heat. Heat can temper the steel, weakening its structure. Sharpening should be performed with light to moderate pressure for optimal results. The general guideline is to use just enough pressure to feel metal being removed, allowing the sharpening tool to do the work. Experts from the Woodworkers Guild of America suggest employing a lighter touch, especially with finer grits, to avoid overheating. -

Insufficient Stroke Length:

Insufficient stroke length refers to short, ineffective strokes that fail to adequately sharpen the edge. Longer and more deliberate strokes can lead to a more honed cutting edge. Users should strive for a smooth, fluid motion throughout the sharpening process. A case study from the Woodsmith website shows that woodworkers who utilize longer strokes report sharper results and faster sharpening times. -

Neglecting the Bevel:

Neglecting the bevel means failing to sharpen the entire face leading to a jagged or uneven edge. Proper attention to both the bevel and the flat side is essential for a sharp and effective chisel. Regularly checking the bevel for wear ensures that each sharpening session maintains the correct profile. Woodsmith’s 2018 article emphasizes the importance of creating a flat surface on the back to provide stability during cutting. -

Using Wrong Sharpening Tools:

Using wrong sharpening tools can lead to ineffective sharpening or even damage to the chisel. Different sharpening methods, including water stones, oil stones, and diamond plates, have unique benefits. It’s vital to select the right tool for the specific chisel type. The 2019 guide by Popular Woodworking stresses that choosing unsuitable tools can result in poor outcomes, such as chipping or rounding over of the chisel’s edge. -

Avoiding Regular Maintenance:

Avoiding regular maintenance means neglecting to sharpen chisels consistently, leading to a decline in performance. Regular sharpening can prolong the life of the chisel and yield better results for users. Woodworkers should implement a periodic sharpening schedule based on usage, ensuring their tools remain effective. A 2021 article by the Woodworking Journal suggests that regular maintenance correlates with improved cutting performance and tool longevity.