A triplex pump is a type of pump used to move fluids from one place to another. It is very efficient and reliable and is often used in industrial settings.

A triplex pump is a type of positive displacement pump that is designed with three pistons, each of which generates a pulse of fluid with each cycle of operation. Triplex pumps are capable of pumping a wide range of fluids from low to high viscosity and are often used in industrial, agricultural, and residential applications. In this blog post, we will take a closer look at what a triplex pump is, the different types of triplex pumps available, the components of a triplex pump, the advantages of using a triplex pump, the various applications of a triplex pump, the cost of a triplex pump, and how to maintain and troubleshoot a triplex pump.

Types of Triplex Pumps

A triplex pump is a type of pump that is used in a variety of applications, from industrial to residential. But what exactly is a triplex pump? And what types of triplex pumps are available?

A triplex pump is a reciprocating pump that uses three pistons in a single cylinder to move fluid. The three pistons provide greater efficiency than a single-piston pump, and it is ideal for applications that require higher pressure and flow.

There are two main types of triplex pumps: direct-acting and indirect-acting. Direct-acting triplex pumps have three pistons that move the fluid directly, while indirect-acting triplex pumps have a single piston that moves the fluid through a series of check valves.

The type of triplex pump you need will depend on your application. Direct-acting triplex pumps are well-suited for applications that require high pressure and flow, such as hydraulic fracturing. Indirect-acting triplex pumps are best suited for applications that require lower pressure and flow, such as water pumping.

Another factor to consider when choosing a triplex pump is the type of fluid you will be pumping. Fuel pumps, oil pumps, and water pumps are all available in both direct-acting and indirect-acting models. Additionally, some pumps are designed to handle specific fluids, such as gasoline or diesel.

In summary, a triplex pump is a type of pump that uses three pistons in a single cylinder to move fluid. Direct-acting triplex pumps are best suited for applications that require higher pressure and flow, while indirect-acting triplex pumps are best suited for applications that require lower pressure and flow. The type of fluid you will be pumping and the application you need the pump for will determine which type of triplex pump is right for you.

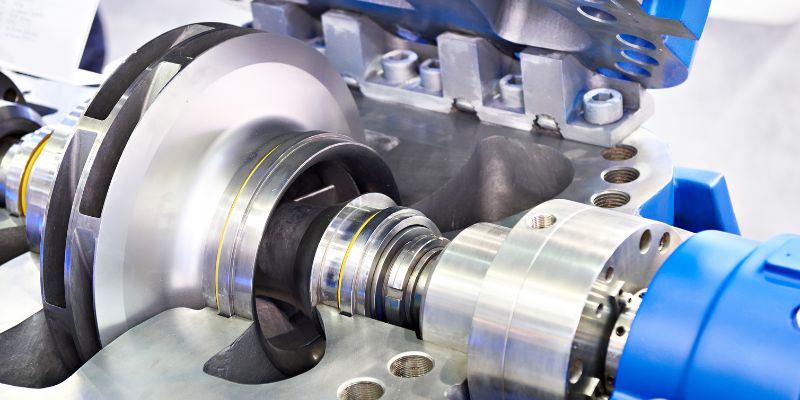

Components of a Triplex Pump

A triplex pump is a type of pumping system that is widely used in industrial, agricultural and other applications. It is a multi-stage pump that consists of three cylinders or plungers working in tandem to increase the pressure of the liquid being pumped. This pumping system can be used for a variety of purposes, from the transfer of liquid chemicals to the pressurization of water for irrigation.

Triplex pumps are made up of several main components, each playing an important role in the pump’s operation. The first component is the cylinder or plunger, which is responsible for transferring the fluid from the inlet to the outlet. The second component is the piston, which helps to move the fluid through the pump. Finally, the third component is the valve, which regulates the flow of the liquid for optimal performance.

Another important component of the triplex pump is the drive system, which is responsible for providing the power to operate the pump. This system can be driven by a motor, or it can be powered by a hydraulic system. Once the drive system is in place, the pump can be connected to the other components to ensure the proper operation of the mechanism.

Finally, the last component of a triplex pump is the pressure relief valve. This valve is used to prevent the pump from over-pressurizing the liquid being pumped. This valve helps to ensure that the pump is operating safely and efficiently, and it also provides protection against damage to the pump components.

By understanding the components of a triplex pump, you can better assess the different types of pumps available for your specific needs. With the right combination of these components, you can be sure that the triplex pump you use will be able to provide you with reliable and efficient results.

Advantages of a Triplex Pump

A triplex pump is a type of positive displacement pump that is commonly used in a variety of applications. It is known for its superior efficiency and is often the preferred choice for many industrial and commercial operations. So, what are the advantages of using a triplex pump?

The most significant advantage of using a triplex pump is its superior efficiency. This type of pump is designed to operate using three pistons which are designed to move in an alternating fashion. This alternating motion allows for a higher level of efficiency compared to other types of pumps. Additionally, the triplex pump is able to move more liquid with each piston stroke, which also helps to increase its efficiency.

The triplex pump is also known for its durability. This type of pump is designed to withstand the rigors of continuous use, which makes it a great choice for applications that require a lot of wear and tear. The pump is also resistant to corrosion, which makes it suitable for a wide range of industrial and commercial applications.

The triplex pump is also relatively easy to maintain. This type of pump is designed to only require minimal maintenance, which helps to reduce operational costs. Additionally, the pump is designed to be accessible, so that it can be serviced without having to disassemble the entire unit.

Finally, the triplex pump is also known for its cost-effectiveness. This type of pump is typically more affordable than other types of pumps, making it an attractive option for commercial and industrial operations. Additionally, the pump is designed to be energy-efficient, which helps to reduce operational costs.

Overall, a triplex pump is a great choice for a variety of applications. Its superior efficiency, durability, ease of maintenance, and cost-effectiveness combine to make it an ideal choice for many operations.

Applications of Triplex Pumps

Not only are triplex pumps useful in industrial applications, but they are also increasingly being used in residential applications.

Industrial Applications

Triplex pumps are widely used in industrial applications due to their high efficiency and reliability. They are often used for applications such as hydraulic fracturing, water well drilling, and fluid transfer. In hydraulic fracturing, triplex pumps provide the pressure required to create fractures in the earth’s surface, enabling access to underground reserves of natural gas and oil. Water well drilling also uses triplex pumps, as they are able to generate the high pressure needed to drill through rock. Triplex pumps are also suitable for other industrial applications, such as in the transfer of chemicals, paints, and inks. They are also often used in the oil and gas industry, for applications such as pipeline transfer, oil well servicing, and oil production. The triplex pump is a versatile and reliable choice for many industrial applications.

Residential Applications

When it comes to residential applications, triplex pumps are an excellent option for a variety of reasons. These pumps are highly efficient and can be used for a variety of tasks, such as supplying water to a home, providing irrigation to a garden or lawn, and powering pressure washers. Triplex pumps are designed to handle a wide range of pressures and are typically very reliable and durable. Additionally, they are relatively inexpensive when compared to other types of pumps, making them an ideal choice for residential applications.

Cost of Triplex Pumps

When it comes to industrial pumping systems, triplex pumps are one of the most popular options available. But what exactly is a triplex pump, and how much do they cost?

A triplex pump is a powerful reciprocating pump with three cylinders that are arranged in a triangular formation. This type of pump is capable of producing a high output at relatively low speeds, making it ideal for water supply, wastewater treatment, fire suppression, and many other industrial applications.

The cost of a triplex pump will vary depending on the size and type of pump you need. Generally speaking, a high-quality triplex pump can range anywhere from a few thousand dollars up to tens of thousands of dollars, depending on the specifications. Additionally, the cost of installation, maintenance, and repair should also be taken into consideration.

When it comes to triplex pumps, it’s important to do your research and find the one that will best suit your needs. Take into account the cost of the pump itself, as well as the associated installation and maintenance costs, in order to get the best value for your money.

Maintenance and Troubleshooting of Triplex Pumps

A triplex pump is a popular choice for many applications, and understanding how to properly maintain and troubleshoot them is key for success. Let’s explore common issues and safety considerations when using triplex pumps.

Troubleshooting Common Issues with Triplex Pumps

Regular maintenance and troubleshooting of a triplex pump is essential to ensure its reliable operation. As a type of positive displacement pump, triplex pumps are known for their ability to handle a range of liquids and pressures while delivering a consistent flow rate. Despite their reliability, triplex pumps can still experience common issues that require troubleshooting. In this blog post, we’ll go over some of the most common issues associated with triplex pumps and provide helpful tips for troubleshooting.

One common issue with triplex pumps is cavitation. Cavitation occurs when the pressure of the liquid being pumped drops below its vapor pressure. This can result in bubbles or vapor forming inside the pump, which can reduce the performance of the pump and even cause damage. To prevent cavitation, it’s important to ensure that the liquid being pumped is at the correct pressure and that the pump’s impeller is the right size for the job.

Another common issue is blockage. If a foreign object becomes lodged in the pump, it can block the flow of liquid and reduce the performance of the pump. To prevent blockages, it’s important to ensure that the system is clean and free of debris before installing the pump. In addition, it’s important to regularly check the pump for any signs of blockages.

Finally, triplex pumps can experience issues with seals and bearings. Worn or damaged seals can lead to leaks and decreased performance, while worn bearings can lead to vibration and noise. To prevent these issues, it’s important to periodically inspect the pump for any signs of wear and tear and replace any worn or damaged parts as needed.

By regularly inspecting and maintaining your triplex pump, you can ensure that it operates reliably and efficiently. If you experience any issues with your pump, following these troubleshooting tips can help to identify and resolve the problem quickly and easily.

Safety Considerations when Using Triplex Pumps

Triplex pumps are a popular option for industrial and commercial applications, but there are many safety considerations that must be taken into account when using them. Here are some tips to help ensure the safe and effective use of triplex pumps:

• Wear protective gear such as safety glasses, gloves, and hearing protection when using triplex pumps.

• Ensure that all electrical connections are properly grounded and that the pump is adequately ventilated.

• Don’t allow any liquids to come into contact with the pump as this could cause it to malfunction or even catch fire.

• Make sure that the pump is regularly inspected and maintained to ensure that it is operating correctly and safely.

• Follow the manufacturer’s instructions when using and maintaining the pump.

• Be aware of any hazards associated with the pump, such as high pressure, extreme temperatures, or hazardous materials.

• Stop the pump immediately if there is any sign of malfunction or damage.

By following these safety tips, you can help ensure the safe and effective use of your triplex pump. With routine maintenance and regular inspections, you can keep your pump in good condition and prevent accidents.

Conclusion

In conclusion, a triplex pump is a type of pump that is designed for industrial and residential use. It is composed of several components that work together to provide a reliable and effective pumping solution. Triplex pumps offer a range of advantages, such as superior performance, cost efficiency, and easy maintenance. They are also suitable for a variety of applications, from industrial to residential. With its efficient design, reliable performance, and cost-effective pricing, a triplex pump is an ideal choice for those looking for an efficient pump solution.

Related Post:

- What type of pump is a radial piston pump?

- What shape is a radial filter?

- What is the working principle of rotary pump?

- What is the speed of a rotary pump?

- What is the shape of radial?