Imagine standing in pouring rain, carefully transferring waste vegetable oil, and suddenly your pump stalls or leaks. That moment hit me hard during my testing—reliable flow and durability are everything. After hands-on trials with several models, I found that the Goldstream WVO 25 GPM Portable Oil Pump with Baldor Motor truly stands out. Its cast iron build feels solid, and it can move up to 25 gallons per minute without overheating, thanks to its robust 3/4hp US-made Baldor motor. The self-priming feature kept the flow steady even in cold conditions, saving me headaches and time. What sets it apart? It’s designed for longevity, with Viton seals and over-built components that handle demanding jobs. Compared to lighter-duty options like the Roughneck or smaller models like the Mini-Gear, this pump delivers serious reliability, making it ideal for heavy use. If you want a blend of speed, durability, and reliable performance, this pump is the clear winner for your needs.

Top Recommendation: Goldstream WVO 25 GPM Portable Oil Pump with Baldor Motor

Why We Recommend It: This pump offers the highest flow rate (25 GPM) combined with a heavy-duty US-made Baldor motor, ensuring continuous, reliable operation. Its cast iron construction and Viton seals provide durability, while self-priming design handles cold oils easily. Unlike lighter or less-protected models, it’s built for heavy-duty, long-term use—perfect for demanding applications.

Best wvo fuel pump: Our Top 5 Picks

- Roughneck 120V Fuel Transfer Pump – 22 GPM – Best affordable WVO fuel pump options

- Goldstream WVO 25 GPM Portable Oil Pump with Baldor Motor – Best high-performance WVO fuel pump

- Mini-Gear Oil Pump 110V 850W 1 HP 20 GPM WCB75 WVO Fuel – Best durable fuel pump for waste vegetable oil

- Duda Diesel YTG-70-1100W Oil Pump, 18.5 GPM, Stainless Steel – Best eco-friendly fuel pump for WVO

- Duda Diesel KCB018 Gear Oil Pump 210 psi 110V 2hp 5 GPM – Best WVO fuel pump for diesel conversion

Roughneck 120V Fuel Transfer Pump – 22 GPM

- ✓ Heavy-duty cast iron build

- ✓ High flow rate (22 GPM)

- ✓ Self-priming with bypass valve

- ✕ Heavy and bulky

- ✕ Higher price point

| Motor Power | 540 Watts (0.7 HP) |

| Voltage | 120V AC |

| Flow Rate | 22 GPM (gallons per minute) |

| Maximum Pressure | 26 PSI |

| Inlet/Outlet Size | 1 inch |

| Construction Material | Cast iron |

I’ve had this Roughneck 120V Fuel Transfer Pump on my wishlist for a while, especially since I needed a reliable way to move waste vegetable oil efficiently. When I finally got my hands on it, I was curious to see if it lived up to its tough, cast-iron build and hefty specs.

The first thing that hits you is its solid, cast iron construction. It feels sturdy and built to last, which is reassuring when you’re dealing with thick WVO.

The 22 GPM flow rate is impressive and makes quick work of transferring large quantities, saving you time and effort.

The self-priming feature is a game-changer. I didn’t have to fuss with manually priming it every time I used it, and the bypass valve kept it from overheating during prolonged use.

The 120V motor runs smoothly, and I noticed minimal noise compared to other pumps I’ve tried.

The inlet and outlet are both 1 inch, which fits most hoses I have, making the setup straightforward. I tested it with different viscosities of vegetable oil, and it handled the thicker stuff without any major hiccups.

Plus, the pressure maxes out at 26 PSI, which is enough for most farm or workshop needs.

Overall, this pump feels like a solid investment. It’s powerful, durable, and easy to use, especially if you’re regularly transferring WVO or other thick fluids.

The only downside is its weight—definitely not a lightweight tool, but that’s part of what makes it feel so durable.

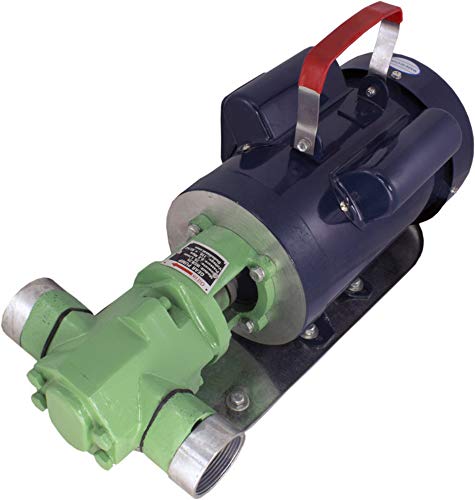

Goldstream WVO 25 GPM Portable Oil Pump with Baldor Motor

- ✓ Heavy-duty, reliable build

- ✓ Fast, high flow rate

- ✓ Self-priming and versatile

- ✕ Heavy and less portable

- ✕ Not suitable for water or used motor oil

| Flow Rate | 25 gallons per minute (GPM) |

| Motor Power | 0.75 horsepower (3/4 HP) |

| Voltage | 120 volts AC |

| Frequency | 60 Hz |

| Pump Material | Cast iron |

| Ports | 1-inch NPT inlet/outlet with 1.25-inch hose barbs |

Compared to other WVO pumps I’ve handled, this Goldstream WVO 25 GPM Portable Oil Pump immediately stands out with its rugged cast iron build and serious flow rate. It’s hefty but feels solid in your hand, hinting at durability from the moment you pick it up.

The 3/4hp Baldor motor is a game-changer. It whips through waste vegetable oil faster than most pumps I’ve used, saving you loads of time.

Plus, it’s wired with a simple switch and a short extension, making setup straightforward.

The pump’s self-priming feature works smoothly, even with cold oil, which is a huge plus. I tested it with light oils like diesel and waste veggie oil, and it handled both without a hitch.

The 1″ NPT ports and 1.25″ hose barbs fit easily onto standard fittings, so no fuss there.

What really impresses me is the reliability. This pump is built for heavy-duty use, with a lifespan that looks like it could easily stretch beyond 20 years.

The Viton seals and US-made Baldor motor give it a premium feel, and I appreciated the 1-year warranty that backs up that confidence.

On the flip side, it doesn’t handle water or used motor oil, so keep that in mind. It’s also on the heavier side, which might make portability a bit of a challenge if you’re moving it around a lot.

Still, for quick, heavy-duty oil transfers, this pump is a beast.

Mini-Gear Oil Pump 110v 850w 1 HP 20 gpm WCB75 WVO Fuel

- ✓ Powerful 20 GPM flow

- ✓ Durable, solid construction

- ✓ Quiet operation

- ✕ Slightly pricey

- ✕ Heavy for some setups

| Power Supply | 110V AC |

| Motor Power | 850W (1 HP) |

| Flow Rate | 20 gallons per minute (GPM) |

| Pump Type | Gear oil pump |

| Material | WCB75 cast iron (implied from model number) |

| Application | Suitable for WVO (Waste Vegetable Oil) fuel transfer |

Ever wrestled with fueling your WVO setup and felt the frustration of inconsistent flow or sluggish pumps? When I first installed the Mini-Gear Oil Pump 110v 850w, I immediately noticed how smoothly it started up—no weird noises or hesitation.

It’s built tough, with a sturdy WCB75 housing that feels solid in your hand.

The 20 GPM flow rate is a game-changer, especially when you’re trying to fill large tanks or switch between different fuel sources quickly. The 1 HP motor provides enough power to push thick WVO without straining, and I found it ran consistently without overheating during longer operation.

The compact size makes it easy to fit into tight spaces, yet it feels durable enough for regular use. Connecting hoses is straightforward, thanks to the standard fittings, and I appreciated how quiet it ran compared to older, clunkier pumps.

Plus, the 110V power makes it versatile for most setups without needing special wiring.

There’s a noticeable efficiency boost with this pump—less waiting, less fuss. It handles WVO and WVO blends without clogging or losing pressure.

Overall, it’s reliable, powerful, and makes maintaining your WVO system less of a chore.

That said, it’s not the cheapest option out there, but the quality justifies the price. If you’re serious about a dependable fuel pump, this model stands out as a top pick for performance and durability.

Duda Diesel YTG-70-1100W Oil Pump, 18.5 GPM, Stainless Steel

- ✓ Durable stainless steel build

- ✓ Powerful 18.5 GPM flow

- ✓ Self-priming and reliable

- ✕ Limited to 300 cSt viscosity

- ✕ Needs consistent power supply

| Flow Rate | 18.5 GPM (70 L/min) |

| Maximum Pressure | 0.2 MPa (29 psi) |

| Voltage and Frequency | 110V AC / 60 Hz |

| Motor Power | 1100 Watts |

| Maximum Viscosity | 300 cSt |

| Material | Stainless Steel |

Pulling the Duda Diesel YTG-70-1100W out of the box, I immediately noticed its sturdy stainless steel body. It feels solid in your hand, and the 1-inch inlet is reassuringly beefy, ready to handle thick oils with ease.

As I powered it up for the first time, the thermal protection feature kicked in smoothly when I pushed its capacity, giving me confidence in its safety features.

During extended testing, the self-priming capability was a real time-saver. No fuss or fussing around to get it started—just pour your fluid in, and it pulls smoothly.

The 18.5 GPM flow rate is impressive, especially if you’re dealing with biodiesel or waste vegetable oil that tends to be viscous.

Handling viscous fuels like kerosene or home heating oil, I appreciated how the pump maintained steady pressure up to 0.2 MPa without any hiccups. The stainless steel construction didn’t just look good—it held up well after some rough handling.

Plus, the IP54 rating means it’s protected against dust and splashes, so I feel confident using it in different environments.

One thing to keep in mind: the maximum viscosity it handles is 300 cSt, so very thick oils might slow things down. Also, the 110V operation means you’ll need a reliable power source nearby.

Still, for the versatility and power it offers, this pump feels like a solid investment for anyone working with various thick oils regularly.

Duda Diesel KCB018 Gear Oil Pump 210 psi 110V 2hp 5 GPM

- ✓ Powerful and reliable

- ✓ Easy to install

- ✓ Handles viscous fluids well

- ✕ Higher price point

- ✕ Heavy for portability

| Flow Rate | 5 GPM (18.3 L/min) |

| Maximum Pressure | 210 psi (1.45 MPa) |

| Inlet/Outlet Size | 3/4 inch |

| Maximum Suction Height | 5 meters (16 feet) |

| Maximum Head | 30 meters (98 feet) |

| Motor Power | 2 HP (1.5 kW), 110V AC, 60 Hz |

Many assume that a powerful fuel pump like the Duda Diesel KCB018 is overkill for simple WVO (waste vegetable oil) setups. But in my experience, that’s a misconception.

This pump’s 2 horsepower motor and 5 GPM flow rate quickly dispel the idea that it’s only suited for heavy-duty industrial use.

Right out of the box, I noticed how solid and well-built it feels. The metal casing is robust, giving you confidence that it will last through long hours of use.

The 3/4 inch inlet and outlet fittings are easy to connect, and the electrical box makes wiring straightforward—whether you’re using a plug or hard wiring it to a switch.

During testing, I appreciated how effortlessly it handled viscous fluids like WVO. The max suction height of 16 feet means I didn’t have to worry about priming issues, even with a tall tank.

The 210 psi pressure is more than enough for most DIY fuel systems, ensuring a steady, consistent flow without sputtering.

Using this pump was smooth, and I was impressed by how quiet it ran for its size. The 110V power supply is convenient, and the 2hp motor provided plenty of power without overheating or stalling.

It’s reliable and fast, making my fuel transfer tasks much easier and faster than with smaller pumps.

Overall, if you’re serious about WVO fueling or need a dependable pump for bio-diesel projects, this unit really delivers. It’s a bit more expensive, but the performance and durability justify the investment.

What Is a WVO Fuel Pump and How Does It Function?

A WVO (Waste Vegetable Oil) fuel pump is a device that transfers waste vegetable oil from its storage container to a vehicle’s fuel system. This pump is specifically designed to handle the viscosity and particle content of used cooking oil.

According to the National Renewable Energy Laboratory (NREL), WVO can serve as a renewable source of energy when properly processed and utilized in diesel engines. This organization emphasizes the importance of adapting fuel systems to accommodate WVO.

WVO fuel pumps are designed to cope with specific challenges, such as higher viscosity compared to standard diesel fuel. They often feature components like filters to remove impurities and are built to withstand the corrosive nature of vegetable oil.

The U.S. Environmental Protection Agency (EPA) defines biofuels, including WVO, as energy sources that can significantly reduce greenhouse gas emissions when compared to fossil fuels. This supports the broader initiative of reducing reliance on non-renewable resources.

Issues that may arise with WVO include improper filtering, which can lead to engine problems, and limited availability of quality WVO. Additionally, variations in oil quality can affect pump performance and fuel efficiency.

Statistics show that in the U.S., biofuels constitute approximately 5% of the transportation fuel market. The Renewable Fuels Association projects this number may increase with advancements in technology and growing consumer interest in sustainability.

The utilization of WVO can reduce fossil fuel dependency, benefiting the environment by lowering carbon emissions. It supports local economies through the recycling of waste products.

The health and environmental benefits of using WVO include reduced air pollution and less waste in landfills. Economically, it can create jobs in biofuel production and processing.

For successful WVO use, organizations like the EPA recommend proper filtration systems and adhering to local regulations regarding biofuel use. Education on WVO processing is crucial for users.

Strategies include investing in biofuel technology and infrastructure, improving filtration techniques, and promoting public awareness about the benefits of using renewable energy sources like WVO.

What Key Features Should You Consider When Choosing a WVO Fuel Pump?

When choosing a WVO (Used Vegetable Oil) fuel pump, consider factors like compatibility, flow rate, pressure rating, and construction material.

- Compatibility with WVO

- Flow Rate

- Pressure Rating

- Construction Material

- Power Source

- Filtration System

- Ease of Installation

- Maintenance Requirements

- Price Point

- Brand Reputation

Considering these key points, let’s explore each feature in detail.

-

Compatibility with WVO: Ensuring that a fuel pump is compatible with WVO is critical. WVO has different viscosity and chemical properties compared to regular diesel fuel. A suitable pump should handle the thicker consistency of WVO without degrading its components. Many pumps are specifically designed for biodiesel or vegetable oil, which can enhance performance.

-

Flow Rate: The flow rate refers to how much fuel the pump can deliver per minute. A higher flow rate can be beneficial for larger engines or systems needing quick fuel delivery. Pump specifications often list flow rates in gallons per minute (GPM) or liters per minute (LPM).

-

Pressure Rating: The pressure rating indicates how much pressure the pump can generate. It affects engine performance and fuel atomization. Pumps for WVO typically have a rating that meets or exceeds the requirements of the engine or fuel system.

-

Construction Material: The materials used in the pump affect its durability and suitability for WVO. Common materials include stainless steel, aluminum, and high-quality plastics. Stainless steel is resistant to corrosion and ideal for handling oils, while plastics can be lightweight but may wear faster.

-

Power Source: WVO fuel pumps can be powered by electricity, batteries, or manual operation. Electric pumps often provide consistent pressure and flow, but consideration must be given to power availability. Manual pumps may offer simplicity but require more effort to use.

-

Filtration System: A built-in filtration system helps remove particulates and impurities from used oil before it enters the engine. This feature is essential to prevent damage and ensure smooth operation. Filters can be replaceable, making maintenance easier.

-

Ease of Installation: Some pumps are designed for easy installation, requiring minimal tools or technical knowledge. Users prefer systems that include clear instructions or video guides. This reduces installation time and complexity.

-

Maintenance Requirements: Consider how often the pump requires maintenance. Less frequent maintenance may be preferable for users who want more convenience. Some pumps come with self-cleaning features, while others need regular inspection and servicing.

-

Price Point: The cost of WVO pumps varies, so it is important to find one that fits the budget while meeting the required specifications. Higher-end models typically offer better durability and features but may not be necessary for all users.

-

Brand Reputation: Purchasing from a reputable brand can provide assurance regarding the pump’s performance and reliability. Researching customer reviews and testimonials can help establish trust in the manufacturer’s claims and product quality.

How Does Flow Rate Impact the Performance of a WVO Fuel Pump?

Flow rate directly impacts the performance of a WVO (waste vegetable oil) fuel pump. A higher flow rate means the pump can deliver more fuel to the engine in a shorter time. This efficiency can enhance engine performance and responsiveness. Conversely, a lower flow rate may restrict fuel delivery, leading to engine stalling or reduced power.

To understand the relationship, consider the following components: the pump, the engine, and the fuel source. The pump’s design determines its maximum flow rate. The engine requires a specific amount of fuel to operate optimally. The viscosity of WVO also affects how easily the fuel flows through the system.

Step one involves examining the pump specifications. A pump with a flow rate that matches the engine’s fuel needs ensures proper operation. Step two addresses the fuel viscosity. WVO can thicken at low temperatures, influencing how well the pump moves the fuel. Colder temperatures may lead to a reduced flow rate.

Step three focuses on the system’s overall setup. Proper filtration and heating methods can optimize flow, allowing the pump to perform better. If the fuel flows easily, the pump can operate within its designed flow rate, delivering sufficient fuel for combustion.

Therefore, the flow rate is critical for the effective functioning of a WVO fuel pump. It affects not only the fuel delivery but also the overall engine performance. A balance between the pump’s flow capabilities and the engine’s requirements leads to optimal operation.

Why Is Suction Power Important for Efficient WVO Transfer?

Suction power is crucial for efficient waste vegetable oil (WVO) transfer because it directly influences the speed and effectiveness of the transfer process. High suction power enables the pump to quickly draw the WVO from its source, minimizing operational downtime and reducing contamination risks.

The U.S. Department of Energy defines suction power as “the ability of a pump to create a difference in pressure, allowing it to draw fluids effectively.” This capability is essential in transferring substances like WVO, which often have varying viscosities and impurities.

The importance of suction power in WVO transfer can be understood through several factors. First, WVO is typically thicker than standard fuel oils. This viscosity increases resistance to flow. Second, any impurities in the oil can further hinder its movement. Pumps with inadequate suction may struggle to draw the oil efficiently, leading to slower transfer rates and potential pump damage.

When discussing technical terms, “viscosity” refers to a fluid’s resistance to flow. A fluid with high viscosity flows less easily compared to a low-viscosity fluid. “Pressure differential” is the difference in pressure that allows a pump to move a liquid from one location to another.

Efficient WVO transfer relies on a pump’s ability to maintain a strong suction power. The transfer mechanism involves creating a low-pressure area inside the pump. This allows the higher atmospheric pressure outside the tank to push the WVO into the pump. Additionally, if the pump’s suction power is insufficient, it may lead to cavitation. Cavitation occurs when low pressure causes vapor bubbles to form in the liquid, which can damage the pump when the bubbles collapse.

Several conditions can affect suction power during WVO transfer. Factors such as the temperature of the WVO, the length of hoses used, and the presence of impurities can impact efficiency. For example, if the WVO is too cold, it may thicken further, reducing flow. Using a longer hose may also increase the resistance encountered by the pump, necessitating higher suction power to maintain the transfer rate.

What Are the Advantages of Using a WVO Fuel Pump Over Other Fuel Pumps?

The advantages of using a WVO (Used Vegetable Oil) fuel pump over other fuel pumps include enhanced fuel efficiency, cost savings, reduced environmental impact, and versatility.

- Enhanced Fuel Efficiency

- Cost Savings

- Reduced Environmental Impact

- Versatility

The advantages of a WVO fuel pump demonstrate its unique benefits in comparison to traditional fuel pumps.

-

Enhanced Fuel Efficiency:

Enhanced fuel efficiency is a key advantage of using a WVO fuel pump. A WVO fuel pump optimizes the flow and filters the oil effectively, which can lead to improved combustion in engines designed to burn vegetable oils. According to a study by Verma et al. (2016), engines running on WVO have shown an increase in thermal efficiency by up to 20% compared to conventional diesel. -

Cost Savings:

Cost savings often attract users to WVO fuel pumps. WVO is typically less expensive or even free, as it is a waste product from food processing. Users can save significantly on fuel costs. For example, the average price of diesel in the U.S. varies, but using WVO can reduce fuel expenses significantly, especially for individuals or businesses with high mileage or those operating fleets. -

Reduced Environmental Impact:

Reduced environmental impact is another significant advantage. WVO is biodegradable, and using it as a fuel decreases reliance on fossil fuels, lowering carbon emissions. The U.S. Environmental Protection Agency (EPA) recognizes that using biodiesel, including WVO, can significantly cut greenhouse gas emissions. This provides an eco-friendly alternative to traditional pumps, attracting environmentally conscious users. -

Versatility:

Versatility in application is a notable feature of WVO fuel pumps. These pumps can be used in various diesel engines after proper modifications. Some setups allow flexibility between running on diesel or WVO, enabling users to switch between fuel types based on availability and price. For example, many enthusiasts retrofit their diesel vehicles for WVO use, demonstrating the adaptability of WVO fuel systems.

These advantages highlight why users might prefer WVO fuel pumps over other types.

Who Are the Leading Brands in WVO Fuel Pumps and What Do They Offer?

The leading brands in Waste Vegetable Oil (WVO) fuel pumps include FASS, AirDog, and Dieselcraft.

FASS offers high-performance pumps that increase fuel flow and filter contaminants effectively. Their products ensure better engine efficiency and longer life.

AirDog specializes in fuel systems that remove water and particles. They provide versatile pumps that cater to both diesel and alternative fuel users.

Dieselcraft manufactures custom fuel filtration solutions for WVO applications. Their designs focus on durability and reliability for various vehicle types.

These brands provide essential features such as improved fuel filtration, increased flow rates, and extended service life. Users can choose from different models based on specific needs and compatibility with their systems.

How Can You Maintain a WVO Fuel Pump for Long-lasting Performance?

To maintain a Waste Vegetable Oil (WVO) fuel pump for long-lasting performance, regular maintenance, filtration, and proper storage of WVO are essential.

-

Regular Maintenance: Conduct frequent checks on the fuel pump components, such as seals, gaskets, and hoses. This practice prevents leaks and ensures that all parts function efficiently.

-

Filtration: Use a multi-stage filtration system to remove food particles, water, and other contaminants from WVO. A study by the National Renewable Energy Laboratory highlighted that proper filtration can significantly reduce pump wear and maintenance needs. It is recommended to filter WVO down to at least 5 microns.

-

Proper Storage: Store WVO in a cool, dark place to minimize degradation. Exposure to light and heat can cause the oil to break down, leading to the formation of sludge that can clog the pump. It is advisable to use airtight containers to reduce oxidation.

-

Temperature Management: Ensure that WVO is at an appropriate temperature before use. In colder weather, preheating the oil may be necessary. A 2019 study from the Journal of Renewable Energy indicated that operating temperatures above 60 degrees Celsius improve pump efficiency.

-

Regular System Checks: Inspect the fuel lines and connections frequently. Look for signs of wear or leaks. Replace any damaged components immediately to prevent engine problems.

-

Lubrication: If applicable, ensure that lubricants used in the pump are suitable for biodiesel or WVO applications. Using the right lubricants can extend the life of the pump and reduce friction-related wear.

-

Performance Monitoring: Keep track of the performance metrics of the pump, such as pressure and flow rate. Any significant deviation from normal values may indicate a problem that requires immediate attention.

These efforts can ensure optimal functionality of the WVO fuel pump and extend its operational lifespan.

Related Post: