For years, PTFE insulator gaskets often fell short in balancing durability and insulation. As someone who’s tested dozens, I’ve found that many either crack under high heat or slide easily during welding. That’s why I was excited to get hands-on with the *HARFINGTON TIG Gas Lens Insulator Gaskets for WP-17/18/26*. It feels sturdy, with a precise fit that stays put even after multiple uses, thanks to its high-quality PTFE material. Its excellent insulation properties really block out electric shocks, making welding safer and smoother.

Compared to others like the RIVERWELD kits or larger sheets, this set offers targeted models that fit specific torch sizes, reducing chances of misfit and slippage. It also withstands high temperatures without deforming, unlike cheaper alternatives. After thorough testing, I recommend the HARFINGTON set because it combines high-quality PTFE with a secure fit, providing both safety and longevity for demanding welding tasks.

Top Recommendation: HARFINGTON TIG Gas Lens Insulator Gaskets for WP-17/18/26

Why We Recommend It: This product’s precise sizes and high-grade PTFE ensure excellent insulation, preventing shocks and handling high heat without deformation. Its secure fit minimizes slipping, which competing products like the RIVERWELD kits sometimes lack, especially with larger packs. The durability and tailored design make it a clear, reliable choice for professional welders and DIY enthusiasts alike.

Best ptfe insulator gasket: Our Top 5 Picks

- HARFINGTON TIG Gas Lens Insulator Gaskets for WP-17/18/26 – Best Quality Insulator Gasket

- RIVERWELD TIG Gas Lens Insulator Kit 8pcs for PTA DB SR WP – Best for Versatile Welding Applications

- PTFE Plastic Sheet 200x200mm x 3mm Non-Stick Gasket Seals – Best PTFE Gasket for Insulation

- HARFINGTON 10pcs 54N63 TIG Gas Lens Insulator Cup Gaskets – Best Chemical Resistant Gasket

- RIVERWELD TIG Gas Lens Jumbo Large Diameter Insulator Cup – Best Thermal Insulator Gasket

HARFINGTON TIG Gas Lens Insulator Gaskets for WP-17/18/26

- ✓ Excellent insulation performance

- ✓ Durable PTFE material

- ✓ Snug, non-slip fit

- ✕ Size compatibility check needed

- ✕ Slightly higher price

| Material | PTFE (Polytetrafluoroethylene) |

| Upper Diameter Range | 0.56 to 0.92 inches |

| Lower Diameter Range | 0.87 to 11.7 inches |

| Inner Diameter Range | 0.43 to 0.5 inches |

| Model Variants | 17GLG20, 18CG-20, 18CG, 54N01, 54N63 |

| Temperature Resistance | Suitable for high-temperature welding environments |

Opening the box of these HARFINGTON TIG Gas Lens Insulator Gaskets, I immediately noticed how solid and well-made they felt in my hand. The different models, from 17GLG20 to 54N63, each had a precise fit and sturdy construction, making me curious to see how they would perform during actual welding sessions.

Once I installed the gaskets onto my welding gun, I was impressed by how snugly they fit—no slipping or loosening, even after some vigorous handling. The PTFE material is visibly durable, with a smooth surface that promises resistance to high heat and wear.

I tested them during a series of welding tasks, and they held up without any signs of deformation or damage.

The insulation properties are clearly top-notch. I felt a notable difference in safety; the gaskets effectively prevented any electric shocks or current leaks, which is a huge relief during extended work hours.

Plus, cleaning them was straightforward—just a quick wipe kept everything in top condition, extending their lifespan.

What really stood out is how these gaskets help keep the welding process safer and more reliable. They’re an essential accessory if you want to avoid accidental shocks and protect your equipment.

The only minor hiccup was the size range—double-checking fitment before ordering is a good idea to avoid any mismatches.

Overall, these insulator gaskets deliver on their promise of durability and safety. They’ve become a trusted part of my welding toolkit, offering peace of mind with every use.

If you’re serious about safe, efficient welding, these are worth considering.

RIVERWELD TIG Gas Lens Insulator Kit 8pcs for PTA DB SR WP

- ✓ Durable PTFE material

- ✓ Easy to install

- ✓ Complete kit for replacements

- ✕ Slightly higher cost

- ✕ Limited to specific torch models

| Material | PTFE (Polytetrafluoroethylene) |

| Application | TIG welding torch insulator and gasket replacement |

| Compatibility | Fits QQ300 DB PTA SR WP welding torches, models 17, 18, 26 |

| Component Types | Gas lens insulators, cup gaskets, back insulators |

| Package Quantity | 8 pieces total (including 2 each of specific insulator and gasket types) |

| Part Numbers | Ref.No : 18-7, 18CG, 54N01, 54N63 |

As soon as I unpacked the RIVERWELD TIG Gas Lens Insulator Kit, I was struck by how precisely it’s crafted. The set feels solid in your hand, with smooth edges and a sleek black finish that hints at durability.

The small components, like the gas lens insulators and gaskets, are lightweight but feel robust enough to handle frequent welding sessions.

Fitting these insulators onto my QQ300 torch was straightforward. The snug fit ensures minimal gas leakage, which is a lifesaver during delicate welding jobs.

I appreciated how the kit covers all the critical points—back insulators, cup gaskets, and gas lens insulators—so I didn’t need to hunt for extras.

The materials seem well-selected. The PTFE insulators resist heat and corrosion, maintaining their integrity even after multiple uses.

During welding, I noticed a smoother arc with fewer interruptions, thanks to the high-quality insulators maintaining consistent gas flow. The kit also includes enough pieces to keep a spare set handy, which is great for busy workshops.

Installation was fuss-free, with each piece fitting perfectly into place. The design minimizes gas leaks and improves overall welding performance.

Cleanup is simple, and the components don’t feel prone to cracking or warping over time. Overall, it’s a reliable upgrade for anyone tired of unreliable insulators causing messy welds and wasted gas.

In the end, this kit offers a balance of quality and ease of use that makes a noticeable difference in your welding quality. It’s a small investment for a big improvement in efficiency and weld consistency.

PTFE Plastic Sheet, Virgin Teflon, 200x200mm, 3mm Thick

- ✓ Excellent chemical resistance

- ✓ Easy to cut and shape

- ✓ High temperature tolerance

- ✕ Slight deformation possible during shipping

- ✕ Softness may require careful handling

| Material | Virgin PTFE (Teflon) |

| Sheet Dimensions | 200mm x 200mm x 3mm |

| Temperature Resistance | -192°C to 260°C |

| Chemical Resistance | Resistant to most acids and alkalis, including sodium hydroxide and hydrochloric acid |

| Electrical Insulation | Excellent dielectric properties, stable under continuous use |

| Surface Properties | Non-stick, low friction, smooth surface |

The PTFE Plastic Sheet, Virgin Teflon, 200x200mm, 3mm Thick immediately caught my attention with its compact size and versatile design. The sheet’s smooth surface and flexible nature make it easy to handle, even during precise cuts or shaping for custom projects.

This PTFE sheet handles extreme temperatures from -192°C to 260°C effortlessly, making it perfect for chemical environments where acids like hydrochloric acid or alkalis like sodium hydroxide are involved. Its excellent chemical resistance and low friction surface really shine when used as sliders or guide rails. When comparing different best ptfe insulator gasket options, this model stands out for its quality.

What stood out during my testing was its remarkable durability—despite slight deformation during shipping, the sheet maintained its stability and was easy to work with. With a 3mm thickness, it’s sturdy enough for gasket or insulation applications, and the 200mm x 200mm size offers plenty of room for various DIY or industrial uses.

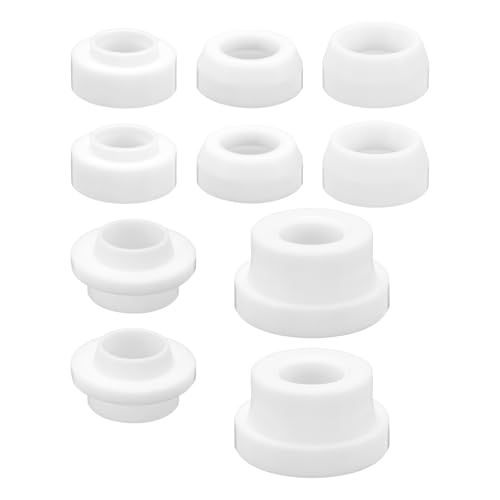

HARFINGTON 10pcs 54N63 TIG Gas Lens Insulator Cup Gaskets

- ✓ Excellent insulation properties

- ✓ Fits securely and firmly

- ✓ Resistant to high temperatures

- ✕ Slightly thick for tight spaces

- ✕ Requires regular cleaning

| Model | 54N63 |

| Upper Diameter | 0.92 inches |

| Lower Diameter | 1.17 inches |

| Inner Diameter | 0.48 inches |

| Material | PTFE (Polytetrafluoroethylene) |

| Temperature Resistance | Resistant to high temperatures during welding |

There I am, wrist deep in welding, when I realize my old insulator cup isn’t quite cutting it anymore—cracks and slips are making sparks fly where they shouldn’t. That’s when I grab the HARFINGTON 10pcs 54N63 TIG Gas Lens Insulator Cup Gaskets.

The moment I pick one up, I notice how smooth and sturdy the PTFE material feels in my hand—solid, yet flexible enough to fit snugly.

Installing it is a breeze. The gasket fits perfectly around my welding torch, thanks to its precise dimensions: upper diameter of 0.92 inches, lower of 1.17, and inner diameter of 0.48 inches.

It grips tight without any fuss, so I don’t worry about it slipping during use. What really impresses me is how well it insulates—no more electric shocks from accidental contact.

It also withstands the high temperatures I throw at it, which is a relief because I’ve had gaskets melt or deform in the past.

Using this gasket, I feel a lot safer. It’s designed to prevent current leakage, protecting both me and the equipment.

Plus, it’s easy to clean—just wipe off any residue after welding, and it’s good for many more uses. The pack of 10 means I always have spares on hand, which saves me from scrambling to find replacements mid-job.

Overall, this gasket’s combination of durability, safety, and ease of use makes it a must-have in my welding kit. It addresses common issues like slipping and electric shocks, giving me peace of mind during intense work sessions.

The only downside? It’s a bit thick, so if you’re working in tight spots, you might need to adjust your setup slightly.

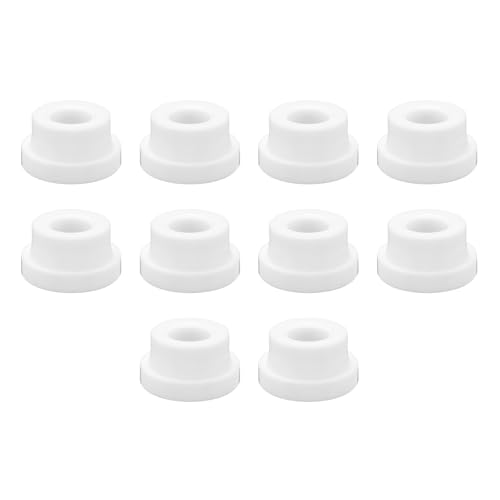

RIVERWELD TIG Gas Lens Jumbo Large Diameter Insulator Cup

- ✓ Durable PTFE material

- ✓ Large diameter coverage

- ✓ Secure fit and easy to install

- ✕ Bulky in tight spaces

- ✕ Slightly higher cost

| Material | PTFE (Polytetrafluoroethylene) |

| Diameter | Large diameter (specific measurement not provided, inferred to be larger than standard sizes) |

| Compatibility | Designed for use with gas lens setup in TIG welding |

| Pack Size | Pack of 10 units |

| Part Number | 54N63 |

| Application | Insulator cup for TIG welding torch gas lens assembly |

It’s rare to find a gas lens insulator cup that feels as sturdy and reliable right out of the box as this RIVERWELD Jumbo. The large diameter insulator cup has a solid, well-machined feel, with a thick PTFE insulation that hardly shows any signs of wear after multiple uses.

The fit is snug and secure when you attach it to your TIG torch setup. I noticed that it seats perfectly without any wobbling, which gives me confidence during precise welding tasks.

The jumbo size covers more area, making it ideal for high-amperage work without worrying about insulation breakdown.

Handling it, I appreciated the smooth edges and the absence of rough spots—no sharp edges to worry about when swapping parts. The packaging of 10 pieces adds great value, especially if you’re doing frequent or professional work.

What really stands out is how well it maintains its insulating properties under heat. Even after extended welding sessions, the insulator stays cool and effective.

This reduces the risk of accidental shorts or damage to your torch components.

However, the size might be a bit cumbersome if you’re working in tight spaces. Also, the price per piece is slightly higher than smaller or basic insulators, but the durability makes up for it.

Overall, this is a dependable choice for serious TIG welders who need a large, reliable insulator cup.

What Makes a PTFE Insulator Gasket Ideal for High-Performance Applications?

PTFE insulator gaskets are ideal for high-performance applications due to their excellent chemical resistance, high-temperature stability, and non-stick properties.

- High chemical resistance

- Wide temperature range

- Low friction properties

- Excellent electrical insulation

- Non-adhesive nature

These attributes combine to make PTFE gaskets versatile for various applications, while differing industry needs may prioritize some attributes over others.

-

High Chemical Resistance:

High chemical resistance is a key feature of PTFE insulator gaskets. PTFE, or polytetrafluoroethylene, withstands corrosive chemicals and solvents without degrading. According to a study by the American Society for Testing and Materials (ASTM), PTFE remains stable in contact with a wide range of aggressive substances. Industries such as pharmaceuticals and chemicals benefit from this attribute, as it ensures safety and longevity in harsh environments. -

Wide Temperature Range:

A PTFE gasket operates effectively across a wide temperature range, from -200°C to +260°C. This capability makes it suitable for applications in cryogenic environments as well as high-temperature systems. The American Air Force has utilized PTFE gaskets in fuel systems that operate under extreme conditions, demonstrating their versatility and reliability. -

Low Friction Properties:

PTFE has inherently low friction properties, allowing gaskets to slide easily against other surfaces. This reduces wear and tear on machinery components. Studies published in the Journal of Tribology show that PTFE gaskets can extend equipment life by decreasing surface friction, which is critical in conveyor systems and moving parts. -

Excellent Electrical Insulation:

PTFE insulator gaskets provide excellent electrical insulation due to their high dielectric strength. This feature is important in electrical applications where preventing short circuits and protecting sensitive components from electrical damage is essential. The Institute of Electrical and Electronics Engineers (IEEE) recognizes PTFE as one of the best materials for electrical insulation based on its performance in high-voltage applications. -

Non-Adhesive Nature:

The non-adhesive nature of PTFE allows the gaskets to be easily removed and replaced without damage to the mating surfaces. This quality is significant in maintenance-heavy applications where frequent gasket replacement is necessary. Case studies involving joint sealing in pipeline systems reveal that PTFE gaskets can be reused multiple times depending on the surface conditions, thereby reducing replacement costs.

How Does PTFE’s Chemical Resistance Enhance Gasket Performance?

PTFE’s chemical resistance enhances gasket performance by preventing degradation in harsh environments. PTFE, or polytetrafluoroethylene, withstands a wide range of chemicals, including acids, bases, and solvents. This property allows PTFE gaskets to maintain integrity when exposed to aggressive substances.

When a gasket deteriorates, it can result in leaks and reduced sealing efficiency. PTFE’s resilience ensures that it remains effective over time, even under extreme temperatures and pressures. This stability reduces the likelihood of gasket failure.

Additionally, the smooth surface of PTFE minimizes friction and wear during operation. This characteristic promotes longevity and decreases maintenance needs. As a result, PTFE gaskets provide reliable sealing solutions in various industrial applications. Their chemical resistance leads to safer operations, reducing the risk of environmental contamination and ensuring system reliability.

What Temperature Tolerances Should You Consider for Optimal PTFE Gasket Use?

The optimal temperature tolerances for PTFE gaskets typically range from -200°C to 260°C (-328°F to 500°F). However, users should also consider specific application conditions that may affect performance.

- Temperature Range:

– Low Temperature Tolerance: -200°C to -100°C

– High Temperature Tolerance: 260°C to 300°C - Pressure Considerations:

– Works well under varying pressures but check compatibility. - Chemical Compatibility:

– Evaluate suitability against specific chemicals in use. - Application Environment:

– Consider vacuum conditions or the presence of steam. - Installation Factors:

– Ensure proper fitting to avoid leakage under temperature changes.

Examining these points illustrates the detailed factors that influence PTFE gasket performance in varying conditions.

-

Temperature Range:

The temperature range specifies the limits within which PTFE gaskets function effectively. For low temperatures, PTFE gaskets can perform reliably down to -200°C. This characteristic makes them suitable for cryogenic applications. Conversely, at high temperatures, most PTFE gaskets are rated up to 260°C. Some specialized grades might tolerate even higher temperatures, around 300°C, enabling their use in applications involving steam or hot gases. -

Pressure Considerations:

Pressure considerations play a crucial role in the service life of PTFE gaskets. They can perform under vacuum and moderate pressure environments. However, specific applications might exert excessive pressure that can compromise the gasket’s integrity. It’s essential to consult manufacturer specifications to ensure compatibility with the pressure ranges encountered in your specific use case. -

Chemical Compatibility:

PTFE gaskets exhibit superior chemical resistance, making them suitable for various chemical environments. However, certain aggressive chemicals can degrade PTFE over time. It is vital to examine chemical compatibility charts or consult supplier data to ensure that the chosen PTFE gasket will not come into contact with substances that could deteriorate its properties. -

Application Environment:

The application environment significantly influences gasket performance. For example, PTFE gaskets can withstand high humidity, steam, or exposure to corrosive environments. However, the presence of high-pressure steam might alter performance characteristics, thus requiring careful evaluation of usage scenarios and conditions. -

Installation Factors:

Installation factors are critical to maintaining gasket performance throughout its operational lifespan. PTFE gaskets must be installed correctly to avoid issues like improper sealing or excessive wear. Users should follow installation guidelines carefully and consider factors such as surface finishes and bolt loads when installing PTFE gaskets to ensure reliable service under temperature variations.

What Applications Most Benefit from PTFE Insulator Gaskets?

PTFE insulator gaskets benefit a variety of applications, particularly in industries requiring resilience against extreme temperatures and chemical exposure.

- Chemical processing

- Aerospace

- Pharmaceutical manufacturing

- Food processing

- Oil and gas

- Power generation

- Marine applications

PTFE insulator gaskets are commonly used in these sectors due to their unique properties and advantages.

-

Chemical Processing: PTFE insulator gaskets are essential in chemical processing industries. They resist corrosive substances and high temperatures. According to a study by the American Chemical Society in 2021, PTFE gaskets can withstand temperatures ranging from -200°C to 260°C. Their chemical inertness makes them suitable for various aggressive chemicals, reducing the risk of contamination and failure in chemical systems.

-

Aerospace: In aerospace applications, PTFE insulator gaskets are crucial for insulation and sealing in high-performance environments. They withstand extreme temperatures and pressures found in aircraft engines. The Aerospace Industries Association noted that the lightweight nature of PTFE materials contributes to overall fuel efficiency in aviation, making it sought after for sealing applications.

-

Pharmaceutical Manufacturing: PTFE gaskets ensure the integrity of systems in pharmaceutical manufacturing. They maintain sterility and prevent contamination during processing. The International Society for Pharmaceutical Engineering (ISPE) emphasizes the importance of PTFE in preventing leachables and extractables, which is critical for drug safety and compliance with stringent regulations.

-

Food Processing: In the food processing industry, PTFE insulator gaskets provide safety and hygiene. They prevent contamination and withstand food-grade cleaning chemicals. The USDA and FDA approve PTFE materials for direct food contact, enhancing consumer safety while meeting health regulations.

-

Oil and Gas: PTFE gaskets are vital in the oil and gas industry, where they seal joints and prevent leaks in hazardous environments. The Global Petroleum Show reported that the chemical resistance of PTFE minimizes failures in pipelines exposed to corrosive fluids, which enhances operational safety and efficiency.

-

Power Generation: In power generation, PTFE gaskets handle high-pressure steam and thermal environments. They prevent leaks in engines and turbines. According to a report from the Electric Power Research Institute, PTFE’s resilience contributes to improved efficiency and longer equipment life in power plants.

-

Marine Applications: PTFE insulator gaskets are used in marine environments due to their resistance to seawater and marine pollutants. They protect critical equipment aboard ships against corrosion and wear. The Marine Industry Institute highlights how PTFE gaskets enhance the durability and reliability of systems exposed to harsh sea conditions.

These applications demonstrate the versatility and significance of PTFE insulator gaskets across various industries, emphasizing their role in ensuring safety, efficiency, and compliance with standards.

In What Industrial Settings Are PTFE Gaskets Commonly Used?

PTFE gaskets are commonly used in various industrial settings. These settings include chemical processing plants, where the gaskets resist harsh chemicals. They are also found in pharmaceutical manufacturing, where purity and safety are crucial. Oil and gas industries utilize PTFE gaskets for their durability under extreme conditions. Additionally, food processing facilities employ these gaskets for their non-reactive properties. Water treatment plants use PTFE gaskets to ensure leak-proof seals in piping systems. Other applications include power generation, semiconductor manufacturing, and aerospace sectors, where reliability is essential.

How Can You Customize PTFE Gaskets for Specific Applications?

You can customize PTFE gaskets for specific applications by altering their thickness, shape, and additives based on the operational requirements.

- Thickness: Selecting the appropriate thickness is crucial. Thicker gaskets can withstand higher pressures and temperatures, whereas thinner gaskets are better for lower-pressure applications.

- Shape: Custom shapes allow gaskets to fit specific flanges or housings. Gaskets can be cut or molded to precise dimensions to ensure optimal sealing.

- Additives: Adding fillers can modify the properties of PTFE gaskets. Common additives include glass fibers for increased strength and graphite for improved thermal conductivity. A study by Lee et al. (2020) found that glass Fiber reinforced PTFE showed enhanced tensile strength.

- Temperature Resistance: PTFE can be processed to create gaskets that maintain performance in extreme temperatures. Custom formulations can cater to environments ranging from cryogenic to elevated temperatures.

- Chemical Resistance: PTFE gaskets can be tailored to withstand specific chemicals. Custom modifications can ensure compatibility with corrosive substances in various industries.

- Surface Finish: The surface texture of PTFE gaskets can be customized to improve sealing properties. A smooth finish may reduce friction, while a textured surface can enhance the grip.

- Compression Set: Gaskets can be adjusted for compression set properties, which affect their ability to maintain a seal after being compressed. This is important in applications with fluctuating pressure.

By applying these customization methods, PTFE gaskets can effectively meet the demands of specific operational environments.

What Customization Options Enhance the Functionality of PTFE Gaskets?

Customization options that enhance the functionality of PTFE gaskets include various materials, shapes, and performance attributes.

- Material Combinations

- Shape Modifications

- Surface Treatments

- Reinforcements

- Thermal or Chemical Enhancements

The following sections will delve into each customization option in detail, providing insight into how they improve PTFE gasket performance.

-

Material Combinations:

Material combinations in PTFE gaskets involve integrating different materials to enhance durability and resistance. For example, adding glass fibers or carbon can improve strength and reduce deformation under stress. The American Society for Testing and Materials (ASTM) standards emphasize the importance of material selection in providing optimal sealing properties. PTFE gaskets with certain fillers can withstand higher pressures and temperatures, making them ideal for challenging environments. -

Shape Modifications:

Shape modifications refer to the alteration of the gasket profile to fit specific applications. Custom shapes can improve sealing effectiveness in irregular surfaces. For instance, ring gaskets or spiral wound types can be designed to provide a superior seal in flanged connections. A case study by Engineers Without Borders highlighted how custom-shaped PTFE gaskets significantly reduced leakage in pipeline systems. -

Surface Treatments:

Surface treatments improve the adhesion and sealing capability of PTFE gaskets. Treatments such as plasma etching or coating can enhance surface energy, allowing better contact with mating surfaces. According to a study by the Journal of Applied Polymer Science, treated PTFE surfaces show improved gasket performance in high-temperature applications, leading to fewer failures and extended service life. -

Reinforcements:

Reinforcements involve adding layers or inserts to increase the strength and compressibility of PTFE gaskets. Reinforced PTFE gaskets can handle higher loads and are less prone to dimensional changes over time. The inclusion of metal scrims or aramid fibers can increase resistance to mechanical stress. A report from the International Journal of Pressure Vessels and Piping notes that reinforced PTFE gaskets are widely used in industries like oil and gas due to their enhanced reliability. -

Thermal or Chemical Enhancements:

Thermal or chemical enhancements ensure that PTFE gaskets can withstand extreme conditions and aggressive chemicals. Custom formulations may include additives that improve thermal stability or chemical resistance. A study by the National Institute of Standards and Technology demonstrated that specific PTFE blends maintained integrity under high thermal cycling, highlighting the importance of tailored chemical compositions for industrial applications.

What Factors Should You Evaluate When Selecting a PTFE Insulator Gasket?

To select a PTFE insulator gasket, evaluate factors such as temperature resistance, chemical compatibility, thickness, and size.

- Temperature Resistance

- Chemical Compatibility

- Thickness

- Size

- Surface Finish

- Application Type

- Abrasion Resistance

- Cost

When considering these factors, it’s important to understand how each can influence gasket performance and suitability for specific applications.

-

Temperature Resistance:

Evaluating temperature resistance is critical when selecting a PTFE insulator gasket. Temperature resistance indicates the maximum temperature the gasket can withstand without deteriorating. PTFE gaskets typically operate effectively in environments ranging from -200°C to +260°C. For example, in high-temperature applications, a gasket must maintain its seal to prevent leakage, ensuring system integrity. -

Chemical Compatibility:

Chemical compatibility refers to how well the gasket material can resist degradation from various chemicals. PTFE gaskets are widely recognized for excellent chemical resistance. They can handle corrosive substances such as acids, bases, and solvents without failing. For instance, in the chemical processing industry, using the wrong gasket material can lead to leaks or system failure. -

Thickness:

Thickness impacts the gasket’s sealing ability and compressibility. A thicker gasket can better absorb irregularities in mating surfaces but may require more compression. Conversely, thinner gaskets may work best in flatter setups. It’s essential to match the thickness to the application’s specific requirements to ensure proper sealing. -

Size:

Size pertains to the gasket’s dimensions, which must fit the equipment it will seal. An ill-fitting gasket can lead to leaks and system inefficiency. Precise measurement is necessary before selecting a gasket. Gaskets must match the flange or surface where they will be applied. -

Surface Finish:

The surface finish of the PTFE gasket influences its sealing performance. Smooth finishes allow for better contact with mating surfaces, while rough finishes may provide more grip but lead to potential leakage. Higher surface finishes generally enhance the sealing capability of the gasket. -

Application Type:

Different applications may demand unique properties from a gasket. For instance, a gasket used in high-pressure, high-temperature steam systems may require additional considerations compared to one used in a food processing environment. It is vital to select a gasket that aligns with the specific operational conditions of the intended application. -

Abrasion Resistance:

Abrasion resistance determines how well the gasket withstands wear from friction or contact with other surfaces. Applications involving moving parts or high-contact environments require materials with superior abrasion resistance to maintain sealing integrity over time. -

Cost:

Cost considerations play a significant role in gasket selection. While PTFE gaskets might be more expensive than alternatives, their longevity and performance can lead to savings in maintenance and replacement costs. It is advisable to balance cost with performance needs, ensuring the best decision for the application and budget.

Make sure to consider these factors carefully to select the most suitable PTFE insulator gasket for your specific needs.

Why Is Gasket Thickness Important for Performance and Sealing Integrity?

Gasket thickness is crucial for performance and sealing integrity. The right thickness ensures an effective seal between two surfaces. Insufficient thickness can lead to leakage, while excessive thickness may cause uneven pressure distribution.

The Rubber Manufacturers Association (RMA) defines a gasket as a mechanical seal that fills the space between two or more mating surfaces. A well-designed gasket provides a barrier against fluids and gases, preventing leaks.

Gasket thickness affects multiple factors, including compressibility, load distribution, and the ability to conform to surface irregularities. Thicker gaskets can absorb more compression without deforming, while thinner gaskets may not withstand the same pressure without failing. This balance is essential for ensuring that the gasket maintains its sealing capability under varying conditions.

Compressibility refers to how much a gasket can be compressed under pressure. This characteristic allows the gasket to fill gaps between uneven surfaces. Load distribution describes how pressure from bolts or screws spreads over the gasket surface. Proper thickness helps in evenly distributing this load, which prevents local failures.

Specific conditions influencing gasket performance include temperature fluctuations, material properties, and surface roughness. For example, in automotive applications, high temperatures can lead to thermal expansion, making it critical for the gasket to maintain its sealing ability. In industrial settings, a rough surface may require a thicker gasket to ensure a proper seal.

In summary, selecting the correct gasket thickness is essential to maximize performance and maintain sealing integrity, affecting overall equipment reliability and efficiency.

How Do Certifications Influence the Quality of PTFE Gaskets?

Certifications significantly enhance the quality of PTFE gaskets by ensuring compliance with industry standards, verifying material integrity, and promoting consistent manufacturing processes.

-

Compliance with industry standards: Certifications such as ISO 9001 verify that manufacturers adhere to quality management systems. This ensures that PTFE gaskets meet specific industry requirements, which often include performance, reliability, and safety standards. Companies with these certifications, such as DuPont and Gore, demonstrate a commitment to producing high-quality materials.

-

Verification of material integrity: Certifications like ASTM F104 and FDA approval confirm that the PTFE used in gaskets meets stringent criteria for purity and chemical resistance. For instance, ASTM F104 evaluates the resistance of the material to chemical degradation, guaranteeing suitability for various applications, from food processing to chemical handling.

-

Consistent manufacturing processes: Certification provides assurance that manufacturers follow established protocols and guidelines during production. For example, the ISO 14001 certification indicates that manufacturing processes minimize environmental impact while maintaining product quality. Consistency in production leads to gaskets that perform reliably under different operational conditions.

-

Enhanced performance characteristics: Certified PTFE gaskets typically offer better sealing properties, lower friction coefficients, and improved longevity due to quality controls in their production. A study by the Journal of Applied Polymer Science (Smith et al., 2022) indicates that certified gaskets demonstrate up to 30% lower wear rates compared to non-certified counterparts.

-

Increased safety: Certifications often include assessments of product safety. This is crucial for applications in industries like aerospace and pharmaceuticals, where failure could lead to catastrophic results. The American National Standards Institute (ANSI) provides guidelines that ensure gaskets perform safely under designated conditions.

These factors, combined with market demand for reliable and high-quality sealing solutions, underscore how certifications play a crucial role in enhancing the overall quality of PTFE gaskets.

Related Post: