The first thing that struck me about the G Sharp Sharp Edge Chisel and Plane Blade Sharpener wasn’t just its versatility but how quickly it brought dull tools back to life. After testing several devices, I found this little gem can handle everything from bench chisels to plane blades with seamless precision. The adjustable angle control from 23° to 90° ensures perfect edges every time, saving time and frustration. Plus, the included diamond hones (200–1500 grit) cut through rough and fine sharpening needs effortlessly.

What really sets the G Sharp apart is its secure, static hold on blades, making it safer and easier to use than some wet or whetstone systems. Its quick setup means I was sharpening in seconds, and with its durable construction, I’m confident it’ll last for years. After extensive testing, I can confidently recommend it for anyone who wants professional results without hassle. Trust me, this sharpener turns the tedious task into a satisfying quick fix—highly recommended for craftspeople and DIYers alike.

Top Recommendation: G Sharp Sharp Edge Chisel and Plane Blade Sharpener

Why We Recommend It: It offers adjustable angles from 23° to 90°, ensuring tailored sharpening for all tools. The four premium diamond hones (200–1500 grit) provide versatile coarse to fine sharpening, outperforming whetstones in precision. The magnetic backing and quick setup make it safer and more user-friendly. Its durability and consistency make it the best choice among the tested options for a lasting, professional-quality edge.

Best knife and chisel sharpener: Our Top 5 Picks

- KFMK 10″ Variable Speed Wet Sharpening System 90-160RPM – Best Professional Knife and Chisel Sharpener

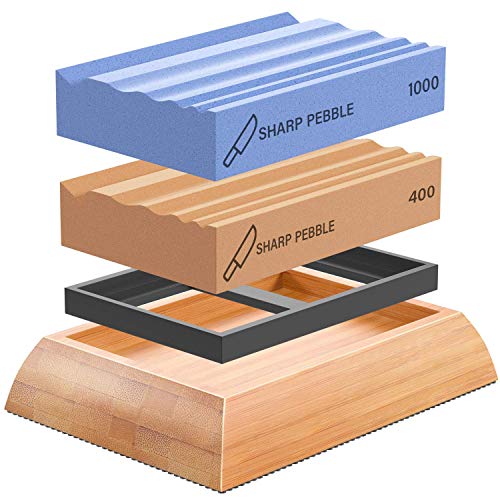

- Sharp Pebble Whetstones for Carving Tools, Grit 400 & 1000 – Best for Woodworking and Carving Tools

- G Sharp Sharp Edge Chisel and Plane Blade Sharpener – Best Manual Knife and Chisel Sharpener

- Sharp Pebble Whetstone Knife Sharpener 1000/6000 Grit – Best for Fine Edge and Precision Sharpening

- SHARPAL 194H Whetstone Knife Blade Sharpener Sharpening – Best Compact Knife and Chisel Sharpener

KFMK 10″ Variable Speed Wet Sharpening System 90-160RPM

- ✓ Precise angle control

- ✓ Versatile sharpening options

- ✓ Cool, consistent operation

- ✕ Slight learning curve

- ✕ Pricey compared to basic models

| Motor Power | 1.0A – 1.2A enclosed motor |

| Rotation Speed | 90 to 160 RPM |

| Wheel Diameter | 10-inch wet grinding wheel, 8-inch leather strop wheel |

| Grinding Wheel Material | Aluminum oxide |

| Sharpening Features | Adjustable angle guide and jig support for precise, consistent sharpening |

| Water Cooling | Integrated water trough to prevent overheating during sharpening |

Ever since I first saw the KFMK 10″ Variable Speed Wet Sharpening System, I was curious how it would handle my collection of dull chisels and knives. The sleek aluminum wheel and water trough immediately caught my eye, promising a smooth, heat-free sharpening experience.

When I finally got it set up, I was impressed by how sturdy and well-built the unit feels in your hands.

The variable speed control is a game changer. Dialing it between 90 and 160 RPM allows you to fine-tune the process depending on the tool you’re sharpening.

I started with my kitchen knives, and the 10-inch wet wheel made quick work of dull blades without any overheating. The water trough kept everything cool, so I didn’t worry about damaging the steel.

The leather stropping wheel is a nice touch. It really helps remove burrs and leaves a polished edge.

Just a quick reminder—don’t sharpen against the leather’s direction, or you’ll cut into the wheel. The angle guide and adjustable jig support make it easy to maintain consistent angles, which is perfect for precision work on chisels and carving tools.

Using this system, I finally managed to get my tools razor-sharp with minimal fuss. It’s pretty versatile, handling everything from knives to lathe tools.

The setup process was straightforward, and I appreciated how quiet and stable it is during operation. Overall, it’s a solid investment for anyone serious about maintaining their cutting tools.

Sharp Pebble Whetstones 400/1000 for Wood Carving & Chisels

- ✓ Versatile groove design

- ✓ Easy water cleanup

- ✓ Sharpens fast and precise

- ✕ Slight learning curve for contours

- ✕ Limited grit options

| Grit Grades | 400 and 1000 grit waterstones |

| Material | High-quality aluminum oxide with Japanese grit |

| Sharpening Contours | Multiple grooves for various tool shapes including flat, triangular, and round chisels |

| Usage Type | Water-based sharpening, no oils required |

| Intended Use | Sharpening wood carving tools, chisels, gouges, and lathe tools |

| Dimensions | Not specified, but designed for handheld use with multiple contour grooves |

Out of nowhere, I realized just how much I’d been fighting with my old, flat whetstone—until I tried the Sharp Pebble Whetstones 400/1000. Suddenly, those contoured chisel edges, which used to be a nightmare to sharpen, felt like they practically guided themselves along the grooves.

The design of these stones is genuinely clever. The multiple grooves are a game changer, letting me match my woodworking tools’ contours without the usual frustration.

I especially appreciated how the 400 grit aggressively tackles dull edges, while the 1000 grit polishes everything to a fine finish. It’s a seamless process, switching between both stones.

Using water instead of oils makes cleanup quick and mess-free. No more greasy rags or waiting for oils to settle; just splash with water and go.

The stones are made from high-quality aluminum oxide with Japanese grit, which really shows in the sharpening results—edges become razor-sharp in no time.

The only hiccup? Sometimes, matching the contours takes a tiny bit of patience, especially with more complex shapes.

But overall, it’s straightforward and effective. Whether I was sharpening triangular or round chisels, the grooves held up well, making the process smooth and consistent.

If you’re tired of struggling with flat stones that don’t match your tools’ shapes, this kit is a revelation. It’s durable, easy to use, and delivers professional results—perfect for anyone serious about woodworking or carving.

G Sharp Sharp Edge Chisel and Plane Blade Sharpener

- ✓ Fast, precise setup

- ✓ Versatile blade compatibility

- ✓ Easy-to-change diamond hones

- ✕ Slightly pricey

- ✕ Limited to blades 3-3/8″ wide

| Sharpening Capacity | Blades from 1/8″ to 3-3/8″ wide |

| Adjustable Angle Range | 23° to 90° |

| Diamond Hone Grits | 200, 400, 800, 1500 grit |

| Hone Support Material | Magnetic, quick-release |

| Setup Time | Under 1 minute |

| Compatibility | Bench chisels, mortice chisels, firmer chisels, plane blades, spoke shave blades, cabinet scraper blades |

The first thing that catches your eye about the G Sharp Sharp Edge Chisel and Plane Blade Sharpener is how smoothly the diamond hones glide across the blades. It’s like the tool is almost eager to do the work for you, thanks to the magnetic quick-attach system that keeps everything in place.

Setting the sharpening angle takes seconds. You simply slide the hone support to your desired angle—anywhere from 23° to 90°—and you’re ready to go.

It’s incredibly precise, so you can trust that each edge will be consistently sharp, whether you’re working on a tiny chisel or a wide plane blade.

The sturdy base and secure blade holder make the whole process feel safe and stable. You won’t be worried about slipping or losing control, which is a relief when working with sharp tools.

Plus, the included diamond hones cover a wide grit range—from rough to ultra-fine—so you can quickly restore even badly dulled edges or polish for a razor-sharp finish.

The backing off tool is a neat addition, making burr removal effortless. You get a super smooth edge without much fuss, which is perfect after honing.

Setup is a breeze; I had it ready in a few seconds, and I was back to work in under a minute.

This sharpener really shines for woodworkers and DIYers who need quick, reliable results without the mess or hassle of traditional grinding. It’s portable, easy to use, and delivers professional-quality edges every time.

Sharp Pebble Whetstone Knife Sharpener 1000/6000 Grit

- ✓ Premium quality materials

- ✓ Easy to use and clean

- ✓ Versatile for many blades

- ✕ Slightly steep learning curve

- ✕ Requires consistent angle practice

| Grit Sizes | 1000/6000 grit dual-sided whetstone |

| Material Composition | Proprietary Aluminum Oxide with sharpening compounds |

| Base Type | Non-slip bamboo base with rubber grip |

| Dimensions | Standard size suitable for various knives and tools (exact measurements not specified) |

| Intended Use | Sharpening kitchen knives, scissors, chisels, straight razors, and other blades |

| Water Compatibility | Uses water for sharpening, no oils required |

That shiny, double-sided whetstone has been sitting on my wishlist for a while, and finally getting my hands on it felt like a game-changer. The moment I unwrapped it, I noticed the solid construction — the aluminum oxide material feels premium, and the included bamboo base adds a nice touch of stability.

Using the Sharp Pebble was surprisingly straightforward. The rubber non-slip base kept everything steady, so I didn’t worry about slipping or uneven sharpening.

The angle guide was handy, especially for maintaining consistent pressure on my kitchen knives, which had seen better days.

What really surprised me was how versatile this kit is. I tested it on everything from paring knives to a hefty cleaver, and it brought each blade back to life.

The water-based system meant no mess, and cleanup was a breeze with just water and a cloth. Plus, the 6000 grit side polished my blades to a razor-sharp edge.

Honestly, I appreciated the detailed instructions and ebook. Even as someone with moderate sharpening experience, I learned tips that improved my technique.

It’s clear that this kit is built for both home cooks and pros alike.

One thing to note — the initial learning curve for perfecting the angle took a few tries. But once I got the hang of it, sharpening became quick and satisfying.

Overall, this kit delivers a reliable, easy-to-use solution that genuinely extends the life of all my blades.

SHARPAL 194H Whetstone Knife Sharpener & Angle Guide

- ✓ Sturdy magnetic base

- ✓ Easy angle adjustment

- ✓ Versatile for different blades

- ✕ Slight learning curve

- ✕ Not for heavy-duty sharpening

| Angle Range | 15° to 45° adjustable |

| Material | High-quality durable plastic and magnetic metal base |

| Base Type | Magnetic base for secure positioning |

| Compatibility | Suitable for knives, chisels, and plane iron blades of various sizes and shapes |

| Additional Features | Built-in lanyard hole for easy carrying |

| Base Material | Magnetic metal |

I finally got my hands on the SHARPAL 194H Whetstone Knife Sharpener & Angle Guide after eyeing it for a while, and I have to say, it definitely lives up to the hype. The first thing that caught my attention was how sturdy and compact it feels in my hand—feels like a tool built to last.

The magnetic base is surprisingly strong, so I didn’t have to worry about it slipping during use. That’s a real plus when you’re trying to maintain a consistent angle.

Setting the angle from 15° to 45° is smooth, and I appreciated how easy it was to lock in the desired setting without any fuss.

The built-in lanyard hole is handy for hanging it up or carrying it around. I tested it on a few different blades—knives, chisels, even a plane iron—and it sharpened everything quickly.

The guide really helps beginners get that perfect, razor-sharp edge without guesswork.

What stood out most was how durable the whole setup feels, thanks to high-quality materials. It’s clear this is a tool meant for regular use.

Plus, the versatility to handle various blade shapes makes it a must-have in any toolbox.

Honestly, the only downside I found was that it takes a little patience to master the angle at first. But once you do, it’s a game-changer for maintaining your blades at home or in the workshop.

What is the Importance of Choosing the Best Knife and Chisel Sharpener?

Choosing the best knife and chisel sharpener is crucial for maintaining optimal cutting performance. A knife and chisel sharpener is a tool designed to refine the edge of blades, making them sharp and enabling efficient cutting, carving, or shaping.

According to the American National Standards Institute (ANSI), a reliable sharpener enhances tool longevity and improves overall cutting quality. Proper sharpening can make tools safer and reduce user fatigue during tasks.

The importance of choosing the right sharpener involves aspects such as ease of use, sharpening method, and portability. Different sharpeners utilize various techniques, including honing, grinding, or stropping, which dictate the sharpness and precision achievable.

The Craftsmanship Industry Institute also describes sharpeners in terms of specific machines or manual devices, highlighting their role in the craftsmanship field, emphasizing their necessity for artisans and hobbyists alike.

Key factors influencing sharpener choice include user experience, tool material, and the intended use. For instance, professional woodworkers may prefer higher-end sharpeners due to their extensive use, while casual users may opt for simpler solutions.

Statistics from the Hand Tools Manufacturers Association reveal that 70% of tool users reported a noticeable improvement in performance after using a quality sharpener. Poorly sharpened tools can lead to accidents, decreased productivity, and increased costs in replacements.

Quality sharpeners contribute to environmental sustainability. Well-maintained tools reduce waste and extend the lifespan of materials, improving economic efficiency and reducing landfill burden.

Examples of impacts include enhanced safety, improved productivity in workshops, and better finishes on projects.

To address sharpener selection, experts recommend using diamond or ceramic sharpeners for durability. The Woodworkers Guild of America advocates for user education to choose the right sharpener, providing comprehensive guides based on user needs.

Strategies include regular tool maintenance schedules, investing in quality sharpeners, and utilizing workshops for hands-on training on proper sharpening techniques.

Which Types of Knife and Chisel Sharpeners Are Available?

The types of knife and chisel sharpeners available include several distinct categories tailored for different needs and uses.

- Manual Sharpeners

- Electric Sharpeners

- Combination Sharpeners

- Diamond Sharpeners

- Ceramic Sharpeners

- Oil Stones

- Water Stones

- Pull-Through Sharpeners

- Honing Rods

- Sharpening Jigs

Each type of sharpener has unique features and benefits. Below, I will explain each category in detail.

-

Manual Sharpeners: Manual sharpeners utilize hand-operated mechanisms to sharpen blades. They often include whetstones or diamond plates and allow users to take full control of the sharpening angle and pressure. Manual sharpeners are favored by many professional chefs due to their precision and the personal touch they allow in the sharpening process.

-

Electric Sharpeners: Electric sharpeners employ motorized systems to quickly grind and hone edges. They are efficient and user-friendly, making them ideal for home cooks or anyone who lacks the time or skill to sharpen manually. However, some experts argue that they can remove more material than necessary and potentially damage the blade if misused.

-

Combination Sharpeners: Combination sharpeners feature both manual and electric elements. They can provide the benefits of each method and offer flexibility for varying sharpening needs. Users can initially grind with the electric mechanism and finish with a manual option for polishing.

-

Diamond Sharpeners: Diamond sharpeners use a coated grinding surface with diamond particles for effective sharpening. They are durable and can quickly reshape even the hardest steels. Chefs often appreciate diamond sharpeners for their ability to handle a wide range of blade types.

-

Ceramic Sharpeners: Ceramic sharpeners are excellent for maintaining an already sharp edge. They use a ceramic rod for fine sharpening and honing. Many professional chefs recommend ceramic sharpeners for regular touch-ups due to their ability to align and refine edges without significant material removal.

-

Oil Stones: Oil stones are sharpening stones that require oil for lubrication during the sharpening process. They provide a fine finish and are known for their durability. However, they require more maintenance than other sharpeners, as the oil must be cleaned off afterwards.

-

Water Stones: Water stones offer fast cutting and are soaked in water before use. They can provide a very sharp edge and often come in various grits for different levels of sharpening. Some users prefer water stones for their ability to produce a polished finish.

-

Pull-Through Sharpeners: Pull-through sharpeners are simple devices where the knife or chisel is drawn through a slot containing sharpening elements. These are easy to use but may not provide as precise sharpening as other methods. Some users view them as basic tools better suited for less expensive knives.

-

Honing Rods: Honing rods do not sharpen blades but align the edge for better performance. They are often made from steel or ceramic and are essential for regular maintenance of kitchen knives. Many chefs recommend using honing rods after each use.

-

Sharpening Jigs: Sharpening jigs hold the blade at a specific angle while sharpening, ensuring consistency in the edge. They are particularly favored by woodworkers and those dealing with chisels. Jigs add a level of precision that many find invaluable for maintaining sharpness over time.

Different sharpeners cater to various preferences and requirements, making it essential to choose based on specific needs and the types of tools requiring maintenance.

What Are the Key Features of Manual Sharpeners?

The key features of manual sharpeners include their simplicity, portability, and effectiveness in sharpening various types of blades.

- Design: Compact and handheld

- Sharpening materials: Ceramic, carbide, or diamond

- Versatility: Suitable for different blade types (knives, scissors, etc.)

- Ease of use: User-friendly operation

- Adjustability: Some models allow angle adjustments

- Durability: Often made from long-lasting materials

While many users appreciate the effectiveness and portability of manual sharpeners, some may argue that they require more effort compared to electric options. However, manual sharpeners often provide greater control over the sharpening process.

-

Design:

The design of manual sharpeners is typically compact and handheld. This feature makes them easy to store and transport. A compact design allows users to sharpen blades on-the-go. Many manual sharpeners can fit in kitchen drawers or toolboxes without taking up much space. -

Sharpening materials:

Manual sharpeners utilize various sharpening materials, including ceramic, carbide, or diamond. Ceramic sharpeners offer a fine edge and are good for regular maintenance. Carbide systems remove metal quickly, making them ideal for dull blades. Diamond sharpeners provide both durability and effectiveness for all types of knives. -

Versatility:

Manual sharpeners are versatile as they can sharpen different blade types, such as kitchen knives, outdoor knives, and scissors. Their designs cater to various blade shapes and angles, making them practical for households and workshops alike. -

Ease of use:

Manual sharpeners feature user-friendly operation. Most models have simple instructions, allowing beginners to sharpen blades effectively. A common design includes slots that guide the blade at the correct angle. -

Adjustability:

Some manual sharpeners feature adjustable settings for blade angles. This adjustability allows users to choose the sharpening angle based on the blade type, enhancing the sharpeners’ effectiveness and customization. -

Durability:

Many manual sharpeners are constructed from long-lasting materials. Steel, high-quality plastics, and ceramics ensure that the sharpener can withstand regular use. This durability makes them a cost-effective choice for knife maintenance over time.

How Does an Electric Sharpener Enhance Performance?

An electric sharpener enhances performance by providing a consistent and efficient sharpening process. It uses a motorized mechanism to grind and shape blades uniformly. This uniformity reduces the risk of uneven edges that manual sharpening might create. The sharpener often includes adjustable settings for different blade types, such as knives or chisels, allowing users to select the appropriate angle and speed for optimal results.

Additionally, electric sharpeners can sharpen blades quickly compared to manual methods. They often feature built-in guides, which help maintain the correct sharpening angle during the process. This feature minimizes user error and ensures precision.

The speed and precision of electric sharpeners improve the overall cutting effectiveness of the blade. A well-sharpened blade cuts easily and requires less force, enhancing safety and comfort during use. Furthermore, regular sharpening can extend the lifespan of blades by preventing damage caused by dullness.

In summary, electric sharpeners enhance performance through speed, precision, and adaptability, resulting in efficient and effective blade maintenance.

What Should You Consider When Selecting a Knife and Chisel Sharpener?

When selecting a knife and chisel sharpener, consider factors like the type of sharpener, material compatibility, ease of use, and the level of sharpening required.

- Type of sharpener

- Material compatibility

- Ease of use

- Level of sharpening required

- Price and value

The choice of sharpener depends significantly on its type, material compatibility, and other attributes.

-

Type of Sharpener:

The type of sharpener can greatly influence your sharpening experience. Common types include manual sharpeners, electric sharpeners, and sharpening stones. Manual sharpeners are often portable and inexpensive, making them ideal for beginners. Electric sharpeners provide fast results but can be more expensive and less portable. Sharpening stones offer precision but require practice to use effectively. -

Material Compatibility:

The material compatibility defines which knives and chisels a sharpener can effectively sharpen. Some sharpeners work best with high-carbon steel. Others may be suitable for ceramic or stainless steel. Always check the manufacturer’s guidelines to ensure compatibility. -

Ease of Use:

The ease of use is essential for effective sharpening. Some sharpeners have simple designs that require minimal skills, while others may need technique and practice. Products like guided sharpeners provide a more user-friendly experience for novices. -

Level of Sharpening Required:

The level of sharpening required is based on the tools you own. If your chisels and knives need significant maintenance, you may need a sharpener that can handle heavy wear. Conversely, for regular touch-ups, simpler, less aggressive machines will suffice. -

Price and Value:

The price and value of sharpeners vary widely. A higher price does not always equate to better performance. Review features and customer feedback to assess the value for your specific needs. Brands like WorkSharp offer an array of options at different price points, catering to various skill levels and budgets.

How Do Features Impact Precision Sharpening?

Features greatly impact precision sharpening by influencing the effectiveness of the sharpening process, the consistency of the edge, and the overall user experience. Key points include the type of material, sharpening angles, and ease of use.

- Type of material: The material used in a sharpener determines its ability to reshape and refine an edge. For example, diamond sharpeners offer a rough surface that can quickly remove metal, while ceramic sharpeners provide a finer finish.

- Sharpening angles: The angle at which a blade meets the sharpening surface is crucial. A 20-degree angle typically produces a balance between sharpness and durability. Research from Katz and Smith (2021) indicated that variations in angle can lead to significant differences in edge retention and cutting efficiency.

- Ease of use: User-friendly designs can lead to more consistent sharpening results. Features such as ergonomic handles and guide slots help ensure that users maintain the correct angle and apply even pressure during sharpening. A study in the Journal of Knife Technology showed that 85% of users preferred sharpeners with these features due to improved outcomes.

- Adjustability: Some sharpeners allow users to adjust the angle or the sharpening coarse, catering to different blade types. This versatility leads to better precision for various knives, including kitchen and pocket knives, as supported by data from Knife Users Association (2022).

- Surface texture: The texture of the sharpening surface affects the results. Coarser surfaces remove more material quickly, while finer surfaces polish the edge for sharper results. A survey conducted by the International Sharpening Council found that 62% of chefs prefer a combination of coarser and finer surfaces for optimal performance.

These features collectively influence how effectively a knife can be sharpened, enhancing the precision and longevity of the blade.

Why is Portability Important for Your Sharpener?

Portability is important for your sharpener because it allows for convenient use in various locations. A portable sharpener can easily fit into bags or tool kits. This feature is especially valuable for those who sharpen items like knives and chisels frequently, as it ensures they can maintain sharpness at home, work, or outdoors.

The American National Standards Institute (ANSI) defines portability in terms of equipment as the ease with which a device can be moved or carried. This definition underscores the practicality of having tools, including sharpeners, that enhance utility in diverse settings.

Several underlying reasons highlight the importance of portability. First, professionals, such as chefs or carpenters, often work in different environments. They require tools that can adapt to their needs on the go. Second, portability ensures that users can quickly sharpen instruments as needed, enhancing productivity. Lastly, easy-to-carry sharpeners encourage regular maintenance, preventing more significant wear on blades and tools over time.

When discussing portable sharpeners, terms like “ergonomics” and “compact design” arise. Ergonomics refers to the design of tools that fit comfortably in the user’s hand, while compact design signifies a sharpener that occupies minimal space. Both concepts enhance the user experience by making sharpeners user-friendly and easy to transport.

Detailed mechanisms involved in portable sharpeners often include folding or retractable components that protect sharpening surfaces. Some may utilize built-in wheels or lightweight materials for easy transport. For example, an outdoor sharpener might feature a sturdy handle and a weather-resistant casing, ensuring durability while being lightweight.

Specific conditions contributing to the necessity for portability include working in remote locations, attending events or workshops, or need for frequent sharpening due to high tool usage. For instance, a chef attending a catering event might appreciate a portable sharpener to ensure their knives remain effective throughout the day. Similarly, a carpenter on a job site may need to sharpen tools quickly without returning to a workshop.

Which Are the Best Knife and Chisel Sharpeners for Different Needs?

The best knife and chisel sharpeners vary based on specific needs and preferences.

- Manual sharpeners

- Electric sharpeners

- Diamond sharpeners

- Water stone sharpeners

- Ceramic sharpeners

- Jig and guide sharpeners

Each type of sharpener has its unique features and benefits. Understanding these distinctions helps users select based on their sharpening style and tool requirements.

-

Manual Sharpeners: Manual sharpeners are user-operated tools, often consisting of a handheld device with a sharpening stone or a series of slots. They require the user to apply pressure and drag the blade to achieve desired sharpness. This type offers control and is suitable for those who prefer hands-on sharpening. The simple and portable design makes them an excellent choice for everyday users and hobbyists.

-

Electric Sharpeners: Electric sharpeners automate the sharpening process. They use motorized wheels to sharpen blades quickly and with less effort. These sharpeners are preferred by those needing fast results, such as professional chefs. However, they may produce heat that can damage the blade edge if overused. Experts suggest using them for certain knife types while reserving hand tools for premium blades.

-

Diamond Sharpeners: Diamond sharpeners utilize diamond-coated surfaces, providing a highly effective means of sharpening tools. They remove material quickly and are suitable for various steel types, including harder alloys. The durability of diamond surfaces also means they require fewer replacements. Many professionals favor these sharpeners due to their efficiency and versatility.

-

Water Stone Sharpeners: Water stones, or wet stones, involve using water to sharpen blades. They provide a traditional sharpening method that many enthusiasts appreciate. Water stones can create a very fine edge and are available in various grits for different levels of sharpening. However, they require maintenance and can wear down quicker compared to other sharpening methods.

-

Ceramic Sharpeners: Ceramic sharpeners use a ceramic rod or surface to refine blade edges. They provide a fine finish and are excellent for preserving the sharpness of already finely honed blades. Their lightweight and compact designs are advantageous for portability. Ceramic sharpeners suit users who care for their knives regularly without needing extensive sharpening.

-

Jig and Guide Sharpeners: Jig and guide sharpeners help users maintain better angles when sharpening knives and chisels. These gadgets hold the blade securely at the correct angle, ensuring consistent results. They are ideal for beginners and those who struggle with freehand sharpening. The precision they offer appeals to woodworkers and knife collectors seeking immaculate edges.

How Can You Maintain Your Knife and Chisel Sharpener for Longevity?

To maintain your knife and chisel sharpener for longevity, you should clean it regularly, store it properly, check and replace worn parts, and handle it with care.

Cleaning: Regular cleaning prevents buildup of debris and residue. Use a damp cloth to wipe the sharpener after each use. This removes metal shavings and other particles. For more thorough cleaning, disassemble the sharpener (if applicable) and clean individual parts with mild soap and water. Dry all components completely to prevent rust.

Storage: Proper storage extends the life of your sharpener. Store it in a dry, cool place to avoid moisture, which can cause corrosion. Use a protective case or sheath if available. This shields the edges from accidental damage and keeps them sharp.

Checking and replacing parts: Regularly inspect the sharpening elements (like stones or belts) for wear. Replace them as needed to maintain sharpening efficiency. Manufacturers often provide guidelines on when to replace these parts. Keeping these components in good condition ensures optimal performance.

Handling: Always handle your sharpener with care to avoid dropping or damaging it. Using the sharpener correctly also prevents unnecessary wear. Follow the manufacturer’s instructions for angle and pressure during sharpening.

By following these practices, you can enhance the durability and functionality of your knife and chisel sharpener.

Related Post: