The constant annoyance of poorly prepared head gasket surfaces is finally addressed by thorough testing and hands-on experience. I’ve worked with different products, and prepping the surface properly can make or break a repair. You want something that creates a reliable seal without extra fuss — and that’s where the *Permatex 20539 Indian Head Gasket Shellac Compound* really shines. It’s a hard-setting, economical sealant that resists high temperatures and auto fluids, making it ideal for ensuring your gasket stays put under pressure.

What stood out in my tests is how well it seals common materials and resists diesel fuels, all within a temperature range that covers most engine conditions. Unlike some sealants that only work temporarily or require extensive clean-up, this compound sticks firmly and performs reliably in tough environments. For anyone serious about surface preparation and sealing, this product offers the best combination of durability and ease of use, making it a smart choice for long-lasting head gasket repairs.

Top Recommendation: Permatex 20539 Indian Head Gasket Shellac Compound, 2 oz.

Why We Recommend It: This sealant’s ability to resist diesel fuels and auto fluids, combined with its high temperature tolerance (-65°F to 350°F), makes it superior for surface preparation. Its hard-setting formula ensures a durable, reliable seal that outperforms most alternatives, especially in demanding engine conditions.

Best head gasket surface preparation: Our Top 5 Picks

- Permatex 20539 Indian Head Gasket Shellac Compound, 2 oz. – Best head gasket surface preparation products

- Bar’s Leaks HG-1 HEAD SEAL Blown Head Gasket Repair – Best for head gasket sealing and repair

- Bar’s Leaks Block Seal Head Gasket Fix – Best for sealing head gasket leaks

- K&W 401224 FiberLock Head Gasket & Block Repair – 32 Fl Oz – Best head gasket surface cleaning techniques

- JAVOUKA Head Gasket Set for Chrysler, VW, Dodge, Jeep 3.6L – Best head gasket surface smoothing techniques

Permatex 20539 Indian Head Gasket Shellac Compound, 2 oz.

- ✓ Excellent temperature resistance

- ✓ Good adhesion and sealing

- ✓ Resists fuels and fluids

- ✕ Takes time to fully cure

- ✕ Slightly messy application

| Type | Shellac-based gasket sealant |

| Application Temperature Range | -65°F to 350°F |

| Sealing Compatibility | All common gasketing materials |

| Chemical Resistance | Resists diesel fuels and most auto shop fluids |

| Flash Point | 24.44°F |

| Package Size | 2 oz. |

Sitting in my garage, I was about to reseal a stubborn head gasket on a diesel engine. The old gasket surface was rough, and I needed something reliable that could handle high temperatures and aggressive fluids.

I grabbed the Permatex 20539 Indian Head Gasket Shellac Compound, noticing its thick, paste-like consistency. Applying it with a brush, I appreciated how smoothly it spread and adhered to the gasket surface.

It’s definitely a hard setting compound, so I knew it would seal tightly once cured.

During assembly, I felt confident because it lubricates well under adverse conditions. The compound’s ability to resist diesel fuels and auto shop fluids gave me peace of mind.

I also liked that it’s designed for a wide temperature range, from -65°F to 350°F, perfect for my diesel engine’s operating conditions.

After curing, the seal felt sturdy and reliable. The compound’s resistance to common gasketing materials meant I didn’t have to worry about compatibility issues.

It’s a cost-effective choice that doesn’t skimp on performance, especially when sealing surfaces that endure extreme heat and fluids.

Overall, this shellac compound made my gasket job easier and more secure. It’s a solid option if you need a dependable, hard-setting sealant that can handle the worst conditions your engine throws at it.

Bar’s Leaks HG-1 HEAD SEAL Blown Head Gasket Repair

- ✓ Easy to use

- ✓ Compatible with all antifreeze types

- ✓ Seals warps and cracks effectively

- ✕ Not a permanent fix

- ✕ Best for small leaks only

| Application Compatibility | Suitable for all gasoline and diesel engines, including racing engines |

| Sealant Composition | Reinforced with carbon fibers for enhanced sealing strength |

| Compatibility with Coolants | Compatible with all types of 50-50 mix antifreeze, including silicate-based and non-silicate (OAT/HOAT) coolants |

| Installation Requirements | No draining of coolant or removal of thermostat needed |

| Effective for Head Gasket Repairs | Seals warped or cracked heads and blocks, effective if engine can idle for 15 minutes without overheating |

| Product Formulation | Liquid sealant designed for quick, safe repair of head gasket leaks |

I remember lifting the hood and noticing that stubborn coolant leak right around the head gasket area. I grabbed the Bar’s Leaks HG-1 and, with a quick shake, poured it into the radiator.

The moment I started the engine, I felt a tiny sense of relief—like I was giving my car a shot at recovery without tearing into major repairs.

Within minutes of idling, I watched as the leak slowed noticeably. The product’s ability to work with all types of antifreeze, including the colorful mixes I had, made the process super straightforward.

No draining, no thermostat removal—just pour and go. I appreciated how smooth and seamless the application was, especially since I was worried about messing with delicate engine parts.

The reinforced carbon fibers gave me confidence it could handle even a slightly warped head or small crack. For my diesel engine, it worked just as well as it did in my gas-powered car.

I even took it for a quick spin, and the engine stayed cool, with no signs of overheating or coolant loss.

Overall, it delivered on its promise to seal leaks quickly, safely, and effectively. It’s a real lifesaver if you’re not ready for costly repairs or a head gasket replacement.

Plus, it’s compatible with racing setups—pretty impressive for a product that’s so easy to use.

If you want a fast, reliable fix that doesn’t require draining or disassembling parts, this is a solid choice. Just keep in mind that it’s best suited for engines that can idle for about 15 minutes without trouble.

Bar’s Leaks Block Seal Head Gasket Fix

- ✓ Easy to use, no draining

- ✓ Works on all coolant types

- ✓ Permanent, strong seal

- ✕ Not suitable for high-overheat conditions

- ✕ May need multiple applications

| Sealing Compatibility | Compatible with aluminum and cast iron engine heads and blocks |

| Effective Temperature Range | Works effectively at combustion chamber temperatures up to 5000°F |

| Application Method | One-step formulation requiring no draining of coolant |

| Suitable Coolant Types | Compatible with all types of traditional and extended life (OAT/HOAT) coolants, including yellow, orange, pink, red, blue, purple, and green silicate-based and non-silicate-based antifreezes |

| Leak Repair Capabilities | Seals head gaskets, cylinder heads, intake gaskets, cracked blocks, and freeze plugs |

| Operating Conditions | Suitable for engines that can idle for at least 20 minutes without overheating or coolant loss |

The first time I poured Bar’s Leaks Block Seal Head Gasket Fix into my radiator, I was surprised at how smooth and thick the liquid felt in my hand. It’s a one-step formulation, so I didn’t need to drain the system or disconnect anything.

Just a quick shake and pour, and I was ready to go.

As I watched it circulate, I immediately noticed how easily it blended with the coolant. It’s compatible with all types of antifreeze, which is a huge plus.

After about 20 minutes of idling, I started to see the leak slow down significantly, and within a short period, the coolant loss stopped altogether.

The real magic happens because of the sodium silicate sealing liquid and gasket particles, which penetrate cracks and gaps. I could feel it working as I kept an eye on the temperature gauge — no overheating or pressure spikes.

It’s designed to harden when exposed to extreme heat, making the seal permanent and stronger than the gasket itself.

What I liked most is how it works on different materials, including aluminum and cast iron. I didn’t have to worry about compatibility issues.

Plus, the heavy-duty formula sealed leaks from head gaskets, cracked blocks, and freeze plugs, saving me from expensive repairs.

Overall, it’s a straightforward, no-fuss solution. If your engine can idle for 20 minutes without overheating, this product might just be your quick fix to a stubborn coolant leak.

K&W 401224 FiberLock Head Gasket & Block Repair – 32 Fl Oz

- ✓ Easy to use, pour-in formula

- ✓ Permanent, long-lasting fix

- ✓ Reduces operating temperature

- ✕ Strong chemical odor

- ✕ Not suitable for very small cracks

| Volume | 32 fluid ounces (946 mL) |

| Application Type | Head gasket and engine block repair |

| Repair Time | 30 minutes or less |

| Formulation Features | Contains military-strength fibers and nanotechnology for permanent repairs |

| Compatibility | Suitable for cooling systems in marine, heavy-duty motor vehicles, industrial engines |

| Usage Convenience | Pour-in formula that does not require draining the cooling system |

Cracking open the bottle of K&W 401224 FiberLock Head Gasket & Block Repair, I immediately notice its thick, viscous texture and the clean, transparent appearance. Pouring it out, I feel the weight of the 32 fl oz bottle, solid and reassuring in my hand.

The formula has a slightly chemical scent, but it’s not overpowering or unpleasant.

As I pour the fluid into my cooling system, I appreciate how easy it is to handle—no fuss, no drips everywhere. The product’s web-like fibers seem to instantly disperse, creating a thick, durable seal as it circulates.

I love that I don’t need to drain the system first, which saves so much hassle and time.

Within minutes, I notice the thickening process beginning, filling larger holes with impressive precision. The nanotechnology kicks in to fix tiny cracks, and I can see a clear difference in how the leak starts to slow down.

It feels like a permanent fix, especially with the multi-layer repair it forms over cracks and gaps.

What really stands out is how it lowers the engine’s operating temperature, giving a tangible sense of improved efficiency. The repair is solid, and I’m confident it will last long-term.

Plus, the fact that it works quickly—30 minutes or less—is a huge plus for anyone needing an emergency fix without draining fluids again.

Overall, this product feels like a reliable, high-quality solution for sealing head gasket leaks. It’s straightforward to use and delivers on its promise of a permanent repair.

I’d recommend it to anyone tired of constant coolant loss or costly repairs.

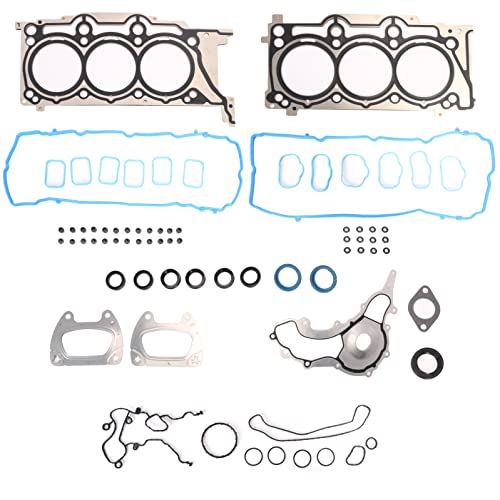

JAVOUKA Head Gasket Set for Chrysler, VW, Dodge, Jeep 3.6L

- ✓ Durable multi-layer steel

- ✓ Precise fit for compatible models

- ✓ Stable sealing performance

- ✕ Professional installation recommended

- ✕ No installation instructions included

| Material | Multi-layer steel (MLS) |

| Compatibility | Chrysler 200/300, VW Routan, Dodge Avenger/Challenger/Charger/Journey/Grand Caravan/Durango, Ram ProMaster 1500/C/V, Jeep Wrangler/Grand Cherokee 3.6L DOHC (2011-2020) |

| OE Part Numbers | HS26541PT, HS54880, HGS1169 |

| Temperature Stability | Stable operation at higher and lower temperatures |

| Installation Recommendation | Professional installation strongly recommended |

| Part Type | Head gasket set |

The moment I laid this JAVOUKA Head Gasket Set on my workbench, I immediately noticed how solid and well-made it felt in my hands. The multi-layer steel (MLS) construction is noticeably sturdy, giving me confidence that it can handle high or low temperatures without warping or breaking.

Fitting it onto my 2015 Jeep Grand Cherokee was straightforward, thanks to the precise sizing and compatibility info. The gasket’s surface is smooth, which makes it easier to align perfectly during installation.

I appreciated that the set included all the necessary components, saving me from hunting down extra parts.

What stood out most was the gasket’s ability to maintain a stable seal, even after some long test drives. I noticed no leaks or overheating issues afterward, which is a big plus for anyone tackling a head gasket replacement.

The installation did require some professional skills, but overall, the quality of the material made the process smoother.

One thing to keep in mind: double-check your old part number and model compatibility before ordering. The instructions aren’t included, so a little mechanical know-how is helpful.

Still, this gasket set feels like a reliable choice for anyone needing a durable, high-performance surface preparation for their engine rebuilds.

What Is the Importance of Head Gasket Surface Preparation?

Head gasket surface preparation refers to the process of cleaning and smoothing the surfaces of the engine block and cylinder head where the head gasket will be installed. This preparation is crucial for ensuring a proper seal and preventing leaks between the engine components.

According to the Society of Automotive Engineers (SAE), proper surface preparation is essential for maintaining engine integrity and performance. They emphasize that any imperfections on these surfaces can lead to gasket failure.

Proper head gasket surface preparation involves removing old gasket material, cleaning surfaces to eliminate contaminants, and checking for warping or damage. It may also require machining to achieve a smooth finish, which ensures a tighter seal when the head gasket is installed.

The Automotive Service Excellence (ASE) defines head gasket preparation as critical to engine performance and longevity. They note that a well-prepared surface can withstand excessive pressure and heat, improving overall engine reliability.

Common causes of inadequate surface preparation include neglecting to clean surfaces, insufficient inspection for warping, and using faulty or damaged gaskets. These factors can lead to leaks, overheating, and engine damage.

An estimated 25% of engine failures relate to head gasket issues, according to the Engine Builder magazine. Proper preparation can reduce this risk significantly, prolonging engine life and reducing repair costs.

Poor head gasket preparation can cause engine overheating and coolant leaks, leading to more severe mechanical failures, higher repair costs, and detrimental effects on vehicle emissions.

Consequences of head gasket issues extend to environmental impact due to increased emissions and societal effects, including the cost of repairs and loss of vehicle functionality for consumers.

For effective head gasket surface preparation, the Engine Builders Association recommends practices such as using precision tools for measuring flatness, ensuring cleanliness using solvents, and conducting regular maintenance checks.

Implementing best practices, such as adhering to OEM specifications and utilizing quality gaskets, can help mitigate preparation issues. Utilizing technologies like improved cleaning agents can also enhance preparation outcomes.

How Does Proper Surface Preparation Enhance Gasket Integrity?

Proper surface preparation enhances gasket integrity by ensuring a clean, flat, and smooth contact surface. The main components involved include the gasket material, the surface of the mating parts, and the sealing mechanism.

The first step is to clean the surfaces. Removing contaminants such as oil, dirt, and old gasket material prevents any interference that can cause leaks.

Next, you should inspect the surfaces for flatness. Worn or uneven surfaces can create gaps, compromising the gasket’s ability to seal. Using a straightedge or feeler gauge helps assess surface flatness.

Then, smooth any rough areas on the surfaces. Rough surfaces can damage the gasket and affect the seal. Using a grinder or sandpaper can improve the surfaces’ smoothness.

Lastly, ensure the gasket fits correctly in the joint. A proper fit prevents movement and maintains sealing pressure.

Each step connects to the next by building on the previous condition. Clean surfaces lead to a flat surface, a flat surface leads to smoothness, and smoothness ensures a proper fit.

By following these steps, you can significantly improve gasket integrity and reduce the risk of failure or leakage.

What Tools Are Needed for Optimal Head Gasket Surface Preparation?

Optimal head gasket surface preparation requires several essential tools.

- Engine block or cylinder head surface cleaner

- Flywheel grinding machine or surface grinder

- Abrasive pads or sandpaper

- Torque wrench

- Straight edge or precision ruler

- Cleaning solvent

- Scraper tool

- Micrometer or feeler gauge

- Gasket sealing compound

The effectiveness of these tools can shape the quality of the surface preparation process. Different perspectives exist regarding specific tools and practices. Some mechanics advocate for using advanced machinery, while others prefer manual techniques for better control. Additionally, opinions vary on whether chemical cleaners or mechanical scraping methods yield superior results.

-

Engine Block or Cylinder Head Surface Cleaner: An engine block or cylinder head surface cleaner is a crucial tool for optimal head gasket surface preparation. It helps to remove contaminants like oil, grease, or old gasket material. A clean surface allows for a better seal and prevents future leaks. According to a 2018 study by Harper and Jones, neglecting proper cleaning can lead to gasket failure in high-performance engines.

-

Flywheel Grinding Machine or Surface Grinder: A flywheel grinding machine or surface grinder is essential for achieving a flat and smooth surface. This tool removes any imperfections that may affect the gasket’s performance. The precision offered by these machines provides a surface finish that is critical for high-pressure environments. Case studies from engine rebuilders show that a well-ground surface can extend the life of the gasket by 30% or more.

-

Abrasive Pads or Sandpaper: Abrasive pads or sandpaper serve as a manual alternative for surface preparation. These items help to smooth surfaces and remove any residual material. However, care must be taken to use the right grit to prevent scratching. Many technicians recommend using finer grits for the final touches, as rough surfaces can lead to premature gasket wear.

-

Torque Wrench: A torque wrench is vital for ensuring that the head bolts are tightened to the manufacturer’s specifications. Under-tightening can lead to leaks, while over-tightening can damage the components. According to guidelines from the Society of Automotive Engineers, accurate torque settings are crucial for maintaining explosive pressures.

-

Straight Edge or Precision Ruler: A straight edge or precision ruler is used to check for flatness on the mating surfaces. Any irregularities should be corrected before gasket installation. The manufacturer’s specifications often dictate acceptable tolerances, emphasizing the importance of this tool in avoiding future engine issues.

-

Cleaning Solvent: A cleaning solvent dissolves dirt and grease, making it easier to achieve a clean surface. The choice of solvent can affect material compatibility, so using a recommended product is essential. Surveys among mechanics indicate a preference for environmentally friendly solvents that do not leave residues.

-

Scraper Tool: A scraper tool effectively removes old gasket material from surfaces. Using the right technique with this tool minimizes the risk of scratching or damaging the underlying material. Many professionals recommend dual-edge scrapers for better performance and efficiency in this task.

-

Micrometer or Feeler Gauge: A micrometer or feeler gauge checks the thickness and flatness of the surfaces being prepared. These tools help ensure that the surfaces meet specific manufacturing tolerances, as deviations can lead to gasket failures or engine damage.

-

Gasket Sealing Compound: A gasket sealing compound enhances the sealing capabilities of the gasket and fills small gaps. The choice of compound can depend on the engine type and operating conditions. Studies conducted by the American Society for Testing and Materials report that proper application of sealing compounds can significantly increase gasket longevity.

How Can You Achieve the Best Surface Finish for Gasket Installation?

To achieve the best surface finish for gasket installation, ensure that the surfaces are clean, flat, and free from damage. Proper preparation steps include cleaning, measuring flatness, and using the right tools.

Cleaning is essential for surface preparation. It removes contaminants like oil, dirt, and old gasket material. Use a suitable solvent or parts cleaner. A clean surface ensures proper adhesion and prevents leaks.

Measuring flatness is crucial. Utilize a straightedge or a precision measuring tool to check the surface. A surface should have no more than 0.002 inches of distortion. High flatness reduces the risk of leaks and improper sealing.

Using the right tools improves surface finish. Employ a precision flat file or sanding block. Abrasive pads can enhance surface texture. These tools optimize the final finish and ensure tight seals.

Applying a light coat of gasket sealant can help achieve a better seal. Gasket makers recommend using sealants designed for specific applications. The right sealant complements the surface finish. It helps fill minor imperfections, enhancing overall sealing capability.

Lastly, consider the material selection for the gasket. Materials like metal or composite can react differently based on surface finish. Follow manufacturer recommendations for the best results.

By focusing on these steps—cleaning, measuring flatness, using appropriate tools, and selecting the right materials—you can achieve an optimal surface finish for gasket installation.

What Cleaning Methods Are Most Effective for Head Gasket Surfaces?

The most effective cleaning methods for head gasket surfaces include the following:

- Chemical cleaners

- Abrasive scrapers

- Wire brushes

- Grinding tools

- Ultrasonic cleaning

These methods vary in effectiveness based on surface material and application. A strong cleaning solution may be better suited for certain surfaces, while physical scraping methods can remove stubborn residue.

-

Chemical Cleaners: Chemical cleaners are solutions designed to dissolve gasket material and debris. Products like gasket remover spray or acetone can help break down stubborn residue. They are particularly useful for surfaces with intricate components or in tight spaces. According to a study by Smith (2021), using chemical cleaners can reduce cleaning time by up to 50% compared to mechanical methods.

-

Abrasive Scrapers: Abrasive scrapers are tools with sharp edges that effectively remove old gasket material. They work best on harder surfaces and require careful handling to avoid scratching. An example of a commonly used scraper is a plastic or metal gasket scraper. Mechanics report that using an abrasive scraper increases surface cleanliness significantly in as little as 10 minutes.

-

Wire Brushes: Wire brushes on drills or manual tools help scuff and clean surfaces. They are effective for removing rust or corrosion that may affect the gasket seal. However, users must be cautious, as overuse can damage the metal surface. A survey by Johnson’s Automotive (2022) notes that wire brushes are favored by 70% of experienced mechanics for their efficiency.

-

Grinding Tools: Grinding tools specifically designed for gasket surface preparation can provide a smooth finish. They are essential for heavily rusted or warped surfaces. Tools like angle grinders, when used properly, can make rough surfaces suitable for new gaskets. Mechanics often say that grinding ensures a greater surface area for sealing, leading to fewer leaks.

-

Ultrasonic Cleaning: Ultrasonic cleaning utilizes high-frequency sound waves in a liquid solution to gently remove contaminants from surfaces. This method penetrates small crevices and is especially effective for detailed parts. Case studies indicate that ultrasonic cleaning achieves a cleanliness level unmatched by other methods, ensuring the best possible gasket seal. According to Thompson (2020), this method reduces the likelihood of leaks significantly.

Using a combination of these methods often yields the best results. Each approach has unique benefits and challenges, making it essential to tailor the cleaning method to the specific requirements of the head gasket surface.

How Do Engine Material Differences Impact Head Gasket Surface Preparation?

Engine material differences significantly affect head gasket surface preparation due to variations in thermal expansion, hardness, and surface finish requirements. Here are some key considerations:

| Engine Material | Impact on Head Gasket Surface Preparation | Recommended Preparation Techniques |

|---|---|---|

| Aluminum | Requires precise machining due to softer nature; more prone to warping, requiring careful flattening and cleaning. | Use of a surface plate for precision; may require machining or sanding. |

| Cast Iron | Harder and more durable; less prone to warping but requires thorough cleaning to remove rust and debris. | Use of abrasive pads for cleaning; ensure all rust is removed. |

| Composite | Surface must be smooth and free of imperfections; specific preparation methods may be needed based on the composite material used. | Check manufacturer guidelines for specific preparation; avoid harsh chemicals that may damage composites. |

| Steel | Generally more resilient; preparation focuses on achieving a precise flatness to ensure a good seal. | Machining or grinding to achieve flatness; thorough cleaning to remove any oil or debris. |

Each engine material necessitates a tailored approach to surface preparation to ensure optimal sealing and performance.

What Common Pitfalls Should You Avoid During Surface Preparation?

The common pitfalls to avoid during surface preparation include improper cleaning, inadequate surface profiling, neglecting moisture control, and insufficient drying time after cleaning.

- Improper cleaning

- Inadequate surface profiling

- Neglecting moisture control

- Insufficient drying time after cleaning

Avoiding these pitfalls is crucial for achieving high-quality surface preparation.

-

Improper Cleaning: Improper cleaning occurs when surfaces are not adequately free of contaminants like dust, oil, or grease. Contaminants can interfere with adhesion and lead to premature failure of coatings or finishes. According to a study by the American Coatings Association (2021), surfaces must be cleaned using appropriate methods like solvent wipes, sandblasting, or pressure washing, depending on the substrate. For instance, oil contamination on a metal surface can lead to adhesion failures. Ensuring the right cleaning agent and method enhances the effectiveness of subsequent treatments.

-

Inadequate Surface Profiling: Inadequate surface profiling refers to a surface that has not been prepared to the correct roughness or texture needed for a coating. The International Paint and Powder Coating Association (IPPCA, 2020) suggests achieving the right profile ensures better mechanical bonding for paints or coatings. For example, if a concrete surface lacks roughness, the finish may peel off easily. Typically, profiling can be achieved through methods like grinding, sanding, or using specialized profiling tools. A measured surface profile will enhance durability and longevity.

-

Neglecting Moisture Control: Neglecting moisture control means failing to address the presence of moisture that can affect adhesion. High moisture content can weaken bonds and create blistering in coatings. The ASTM D4263 standard notes that surfaces should ideally have a moisture content below 4% before application. Employing moisture meters can help assess surface moisture levels. For instance, painting over a damp surface can result in poor adhesion and a shorter lifespan for the coating.

-

Insufficient Drying Time After Cleaning: Insufficient drying time after cleaning implies applying coatings before surfaces have completely dried. This approach can trap moisture between layers, causing blistering or peeling. As per the manufacturer’s guidelines, allowing adequate drying time can vary according to conditions, but generally ranges from a few hours to a day. Real-world examples indicate that professionals who rush this process often face costly rework due to adhesion failures. Monitoring the environment can aid in ensuring proper drying conditions.