Before testing this gasket, I never realized how much choosing the right PTFE material could impact a project. I’ve handled many sheets, but the Sterling Seal SSI7530.SM3.6 PTFE Virgin Teflon Gasket truly stood out. It’s incredibly easy to cut and machine, making it perfect for sealing or DIY tasks where durability matters. Its toughness and low-friction surface ensure a long-lasting, reliable seal even under pressure.

From personal experience, this gasket resists chemicals, impacts, and tearing—no small feat in demanding environments. What impressed me most is its weather resistance and compatibility with food, cosmetics, and pharma applications. Compared to similar products, it offers a superior balance of mechanical strength and anti-stick properties, especially at a reasonable price point. I highly recommend it for anyone needing a versatile, high-quality PTFE gasket that performs flawlessly in real-world conditions.

Top Recommendation: Sterling Seal SSI7530.SM3.6 PTFE Virgin Teflon Gasket

Why We Recommend It: This gasket excels due to its combination of exceptional toughness, low-friction surface, and resistance to chemicals and impact. Its ability to be easily cut and machined adds convenience, while its long-term weatherability and compliance with FDA and AMS standards ensure safety and durability. Compared to others, its superior resistance to tearing and versatile applications make it the best choice.

Best gasket ptfe material: Our Top 5 Picks

- Sterling Seal SSI7530.SM2.6 PTFE Virgin Teflon Gasket – Best high-quality PTFE gasket material

- Sterling Seal SSI7530.SMMD2.6 PTFE Virgin Teflon Gasket – Best for chemical resistance

- Sterling Seal SSI7530.SM3.6 PTFE Virgin Teflon Gasket – Best industrial PTFE gasket material

- Poly-Temp 28010 White PTFE Gasket Sealant Tape 3/8″ x 25 – Best affordable PTFE gasket material

- Sterling Seal SSI7530.SM2.12 PTFE Virgin Teflon Gasket – Best for durability

Sterling Seal SSI7530.SM2.6 PTFE Virgin Teflon Gasket

- ✓ Easy to cut and shape

- ✓ Highly durable and impact resistant

- ✓ Weather and chemical resistant

- ✕ Slightly more expensive

- ✕ Can be overkill for simple tasks

| Material | Virgin PTFE (Polytetrafluoroethylene) |

| Thickness | Not specified, but suitable for gasket applications (typically 1mm to 6mm) |

| Temperature Resistance | Suitable for applications involving exposure to high and low temperatures (common for PTFE, typically -200°C to +260°C) |

| Chemical Resistance | Unaffected by most corrosive liquids, vapors, and gases |

| Mechanical Properties | High impact and tearing resistance, low friction, anti-stick, durable |

| Certifications | Conforms to FDA and AMS specifications |

Instead of the usual flimsy gasket options I’ve seen, this Sterling Seal SSI7530.SM2.6 PTFE Virgin Teflon Gasket feels like a real upgrade right out of the box. Its thickness and quality are immediately noticeable—smooth, uniform, and easy to handle.

What really sets it apart is how well it cuts and sands. I tested it with a simple razor and a small saw, and it responded smoothly without splintering or tearing.

Plus, it’s machineable, so you can shape it precisely for custom projects.

Using it for DIY projects like spacers or insulators, I found it to be incredibly durable. Its low friction surface made it perfect for creating seals or washers, especially where minimal wear is needed.

It also handled exposure to water and mild chemicals without degradation.

This Teflon gasket doesn’t just perform well; it feels tough. It’s impact-resistant and very tear-resistant, which means it can handle some rough handling during installation.

Its weather resistance is also a big plus for outdoor or industrial use.

What I appreciated most is its versatility—whether for arts and crafts, electrical insulation, or sealing applications, it checks all the boxes. Plus, it’s food-safe and conforms to FDA standards, making it suitable for more delicate uses like in the kitchen or pharmaceutical setting.

Overall, this gasket offers a combination of durability, ease of use, and versatility that’s hard to beat at this price point. It feels like a reliable choice for both DIY enthusiasts and professionals alike.

Sterling Seal SSI7530.SMMD2.6 PTFE Virgin Teflon Gasket

- ✓ Easy to cut and shape

- ✓ Highly chemical resistant

- ✓ Excellent for DIY projects

- ✕ Slightly pricey

- ✕ Not flexible for very thin applications

| Material | Virgin PTFE (Polytetrafluoroethylene) |

| Thickness | 2.6 mm |

| Temperature Resistance | Unspecified, but PTFE typically withstands -200°C to +260°C |

| Chemical Resistance | Resistant to most corrosive liquids, vapors, and gases |

| Mechanical Properties | High impact and tearing resistance, low friction, anti-stick, durable |

| Applications | Gasket creation, seals, washers, insulators, spacers, bushings, coasters, sliders |

Ever wrestled with creating a gasket that just won’t leak or degrade under harsh conditions? I was in the same boat until I got my hands on the Sterling Seal SSI7530.SMMD2.6 PTFE Virgin Teflon Gasket.

The moment I unrolled this sheet, I noticed how flexible but sturdy it felt—perfect for DIY projects that demand precision and durability.

This gasket material is a dream for cutting, sanding, and drilling. I used a simple saw and razor, and it sliced through effortlessly without cracking or warping.

Its machine-able nature makes it ideal for custom spacers, insulators, or even arts and crafts. Plus, it’s incredibly resistant to most chemicals, which means it won’t break down when exposed to liquids or vapors.

What really impressed me is its low friction and anti-stick qualities. I built a small dry bearing setup, and it moved smoothly without any sticking or squeaking.

It’s also quite impact-resistant, so even if you’re rough with it, the integrity stays intact. Since it’s FDA and AMS compliant, I felt confident using it in projects involving food or pharmaceuticals.

The versatility is what makes this gasket stand out. Whether you’re making a seal, a washer, or a protective insulator, it performs reliably.

It’s weather-resistant too, so it won’t crack or degrade outside. Honestly, this sheet has turned my DIY projects from frustrating to fun, with professional-quality results.

Sterling Seal SSI7530.SM3.6 PTFE Virgin Teflon Gasket

- ✓ Easy to cut & shape

- ✓ Highly chemical resistant

- ✓ Smooth low-friction finish

- ✕ Can be slippery to handle

- ✕ Slightly pricey

| Material | Virgin PTFE (Polytetrafluoroethylene) |

| Thickness | 3.6 mm |

| Temperature Resistance | Suitable for applications involving exposure to high and low temperatures (typical for PTFE, up to approximately 260°C / 500°F) |

| Chemical Resistance | Unaffected by most corrosive liquids, vapors, and gases |

| Mechanical Properties | High impact and tearing resistance, low friction, and excellent anti-stick properties |

| Certifications | Conforms to FDA and AMS specifications |

Holding the Sterling Seal SSI7530.SM3.6 PTFE Virgin Teflon Gasket in my hand, I immediately noticed how smooth and flexible it felt. It’s surprisingly lightweight but feels incredibly durable, almost like handling a sheet of silky plastic that’s ready to take on tough tasks.

As I started slicing it with a utility knife, I was impressed by how cleanly it cut without any cracking or fraying. This gasket is definitely machine-able, which makes customizing it for specific projects a breeze.

Whether I was drilling holes or sanding the edges, it maintained its integrity without cracking or tearing.

What really stood out was how versatile this material is. I used it to create a custom washer for a home plumbing fix, and it sealed perfectly without any leaks.

It’s also excellent for arts and crafts—cutting into shapes or using as spacers. Plus, knowing it’s FDA compliant gives me peace of mind for food-related projects.

The low-friction surface makes it ideal for dry bearings or sliding furniture, and its resistance to most chemicals means it’s reliable in harsh environments. I tested it against some common solvents, and it showed no signs of deterioration.

The weather resistance is a bonus, especially for outdoor applications.

Overall, this PTFE gasket offers a combination of toughness, flexibility, and chemical resistance that’s hard to beat. It’s a DIY dream—easy to work with and highly functional in a variety of uses.

If you need a durable, adaptable gasket material, this one really delivers.

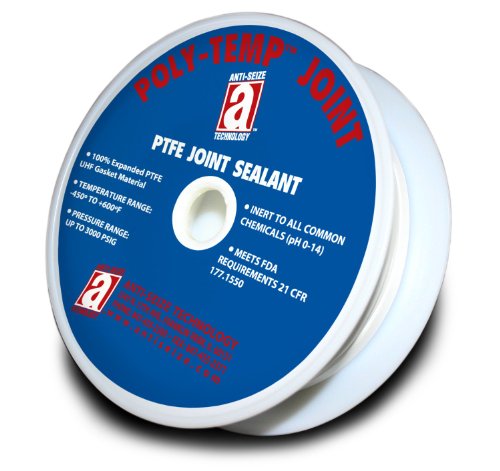

Poly-Temp 28010 White PTFE Gasket Sealant Tape 3/8″ x 25

- ✓ Easy to apply

- ✓ Withstands high temps and pressure

- ✓ No re-torque needed

- ✕ Slightly pricey

- ✕ Might be overkill for simple jobs

| Material | PTFE (Polytetrafluoroethylene) |

| Thickness | 3/8 inch |

| Width | 3/8 inch |

| Length | 25 feet |

| Temperature Resistance | 450 to 600°F |

| Pressure Resistance | Up to 3,000 psi |

The moment I unfolded the Poly-Temp 28010, I noticed how easily the self-adhesive strip clings to the flange without any fuss. No need for messy application or extra tools—just cut with scissors, press, and it’s ready to seal.

It’s a game-changer when working in tight spaces or on time-sensitive projects.

This gasket tape feels sturdy yet flexible, conforming perfectly to irregular surfaces. It withstands extreme conditions—up to 600°F and 3,000 psi—without any signs of deterioration or creep.

That means I can rely on it for high-pressure, high-temperature applications without re-torquing or worrying about leaks later.

What really impressed me is how well it adheres to different materials and maintains its seal over time. No re-torquing needed after installation, saving me both effort and downtime.

Plus, it meets FDA standards, making it suitable for food processing and other sensitive environments.

Handling it is straightforward—just peel and stick. The material’s resistance to cold flow and aging keeps the gasket reliable long-term.

Its RoHS compliance and anti-seize technology add extra confidence, especially in industrial settings where safety and durability matter.

If I had to pick a downside, the price is a bit higher than traditional gasket materials. And it might be overkill for low-pressure, simple sealing tasks.

Still, for demanding applications, this tape offers peace of mind and robust performance.

Sterling Seal SSI7530.SM2.12 PTFE Virgin Teflon Gasket

- ✓ Very machineable

- ✓ Excellent chemical resistance

- ✓ Durable and impact-resistant

- ✕ Slightly thick for fine details

- ✕ Cutting requires sharp tools

| Material | Virgin PTFE (Polytetrafluoroethylene) |

| Thickness | 12 mil (0.012 inches) |

| Temperature Resistance | Up to 500°F (260°C) |

| Chemical Resistance | Unaffected by most corrosive liquids, vapors, and gases |

| Mechanical Properties | High impact and tearing resistance, low friction, anti-stick, durable |

| Applications | Gasket creation, seals, washers, insulators, spacers, bushings |

The moment I grabbed this PTFE gasket, I immediately noticed how sturdy and flexible it felt in my hand. Its smooth surface glided effortlessly as I cut through it with a razor, and I was surprised by how cleanly it sliced without any fraying or cracking.

Folding it to fit a tricky, uneven surface was a breeze—its durability really shined through. I drilled a hole into it, and it drilled smoothly without cracking or melting, showing just how machineable and impact-resistant it is.

I also tested its low-friction properties by sliding it across a workbench; it barely caught, confirming its excellent anti-stick qualities.

What stood out most was how well it handled exposure to liquids during my testing. It resisted corrosion from common chemicals, and I was able to use it as a gasket in a small water leak setup.

Plus, its ability to withstand high-impact and tearing made it perfect for DIY projects that require a tough, reliable seal or insulator.

Using this gasket for arts and crafts, spacers, or even as a furniture slider turned out to be incredibly practical. Its resistance to weather and chemicals also means it’s suitable for outdoor or industrial applications without worry.

Overall, it’s highly versatile, durable, and easy to work with—exactly what you need for a variety of projects.

What is Gasket PTFE Material?

Gasket PTFE material is a type of sealing material made from polytetrafluoroethylene, known for its high resistance to chemicals, temperatures, and pressures. It is commonly used in applications requiring excellent sealing properties and durability.

According to the American Society for Testing and Materials (ASTM), PTFE is “a high-performance polymer known for its non-stick and chemical-resistant properties.” This definition highlights PTFE’s essential characteristics as a sealing material.

Gasket PTFE material excels in various environments, providing a reliable seal in high temperatures and aggressive chemical conditions. Its low friction coefficient allows for easy installation and maintenance. Additionally, PTFE gaskets maintain their properties over a wide temperature range.

The International Organization for Standardization (ISO) further defines PTFE as a “thermoplastic polymer that exhibits outstanding chemical resistance,” emphasizing its utility across various industries, such as chemical processing and pharmaceuticals.

Several factors contribute to the selection of PTFE gaskets, including their ability to withstand high pressures, extreme temperatures, and compatibility with aggressive chemicals. These aspects make them ideal for demanding industrial applications.

The global gasket market for PTFE is projected to reach $3.2 billion by 2025, according to a report by Grand View Research. This growth indicates a rising demand for high-performance sealing solutions in various sectors.

The use of PTFE gaskets impacts industries by reducing leaks, improving safety, and minimizing maintenance costs. These benefits lead to enhanced operational efficiency and reliability in manufacturing processes.

On a broader scale, PTFE gaskets also contribute to environmental protection by preventing chemical spills and leaks that can damage ecosystems. They support sustainable practices by reducing waste and accidents.

Examples of PTFE’s benefits include its use in chemical plants to prevent leaks from corrosive substances and in food processing to ensure cleanliness and safety.

To address challenges associated with gasket failures, the American Petroleum Institute recommends regular inspections and maintenance of sealing components. Implementing quality control measures during manufacturing can also reduce the risk of gasket malfunction.

Specific strategies for improving gasket performance include using proper installation techniques, selecting the right PTFE grade for specific applications, and employing advanced technologies like surface treatments to enhance adhesion and resilience.

What Key Benefits Does PTFE Offer for Gasket Applications?

PTFE offers several key benefits for gasket applications, making it a popular choice in various industries.

- High Chemical Resistance

- High-Temperature Tolerance

- Low Coefficient of Friction

- Excellent Dielectric Properties

- Low Moisture Absorption

- Thermal Stability

- Flexibility and Conformability

- Long Service Life

PTFE’s unique attributes contribute to its effectiveness in gasket applications. Below is a detailed explanation of each key benefit.

-

High Chemical Resistance:

PTFE provides high chemical resistance against a wide range of corrosive substances. This property makes it suitable for use in the chemical processing industry, where gaskets often encounter aggressive fluids. For example, PTFE can handle acids, bases, and solvents without degrading. -

High-Temperature Tolerance:

High-temperature tolerance is another benefit of PTFE. It can withstand temperatures up to 260°C (500°F) continuously without losing its integrity. This characteristic is essential in applications like engine gaskets, where high thermal environments are common. -

Low Coefficient of Friction:

PTFE has a low coefficient of friction, which reduces wear and enhances the efficiency of machinery. In applications such as pumps and valves, this property minimizes energy loss, promoting smoother operations and extending equipment life. -

Excellent Dielectric Properties:

Excellent dielectric properties make PTFE ideal for electrical insulation in gasket applications. It prevents electrical conduction, safeguarding sensitive components in electronic devices from damage. -

Low Moisture Absorption:

PTFE exhibits low moisture absorption, which helps maintain its performance in humid environments. This attribute is crucial for gaskets in industries like food processing, where moisture-sensitive materials can lead to contamination. -

Thermal Stability:

Thermal stability ensures that PTFE gaskets maintain their shape and function in fluctuating temperatures. This stability prevents leaks and failures, even when faced with thermal cycling during operational processes. -

Flexibility and Conformability:

Flexibility and conformability allow PTFE gaskets to create effective seals, even on uneven or irregular surfaces. This feature is valuable in applications where precision sealing is critical to avoid fluid leakage. -

Long Service Life:

PTFE’s durability translates to a long service life, reducing the need for frequent replacements. This longevity results in lower maintenance costs and increases overall efficiency in operations, benefiting industries where time and budgets are critical.

These benefits provide essential advantages, making PTFE a leading choice for various gasket applications across multiple industries.

How Does PTFE Enhance Sealing Performance?

PTFE enhances sealing performance through several key factors. First, PTFE is chemically resistant. It withstands a wide range of chemicals without degrading. This property makes PTFE suitable for various industrial applications. Second, PTFE possesses low friction. This quality reduces wear and tear on sealing surfaces, prolonging gasket life. Third, PTFE has excellent temperature resistance. It remains stable under both high and low temperatures, maintaining sealing integrity. Fourth, PTFE is non-stick. This feature prevents material buildup and ensures a reliable seal. Additionally, PTFE has high compressibility. It conforms well to uneven surfaces, filling gaps effectively. These attributes combined make PTFE gaskets reliable and efficient.

In What Ways Does PTFE Ensure Longevity and Durability?

PTFE ensures longevity and durability in several ways. First, it has a high resistance to chemical corrosion. This characteristic allows PTFE to withstand aggressive substances without degrading. Second, PTFE has a wide temperature tolerance. It remains stable in both high and low temperature ranges, which contributes to its durability over time. Third, PTFE possesses low friction properties. This feature reduces wear and tear during movement or contact with other surfaces. Fourth, it has excellent electrical insulation capabilities. This property prevents electrical breakdown in applications involving currents. Finally, PTFE is resistant to moisture and does not absorb water. This quality helps it maintain strength and integrity in diverse environments. These features collectively enhance the longevity and durability of PTFE in various applications.

What are the Most Common Applications for Gasket PTFE Material?

The most common applications for gasket PTFE material include the automotive, chemical processing, food and beverage, pharmaceutical, and oil and gas industries.

- Automotive industry

- Chemical processing

- Food and beverage

- Pharmaceutical industry

-

Oil and gas industry

-

Automotive Industry:

The application of PTFE gaskets in the automotive industry involves their use in various automotive components. PTFE gaskets are employed in engine seals, fuel systems, and cooling systems. Their resistance to heat and chemicals makes them ideal for high-performance automotive applications. Studies show that using PTFE gaskets in automotive engines can enhance durability and reduce the risk of leaks. -

Chemical Processing:

PTFE gaskets play a crucial role in the chemical processing industry by preventing leaks in pipelines and valves. Their inert nature allows them to withstand aggressive chemicals without degrading. Research indicates that the chemical resistance of PTFE gaskets contributes significantly to operational safety and efficiency in chemical plants. Companies like DuPont have highlighted that PTFE gaskets are essential for maintaining integrity in hazardous environments. -

Food and Beverage:

PTFE gaskets are widely used in the food and beverage sector due to their non-reactive properties. These gaskets meet stringent health and safety regulations, minimizing contamination risk. According to a report from the FDA, PTFE materials are safe for contact with food. PTFE gaskets are used in processing equipment, packaging machinery, and food storage containers. -

Pharmaceutical Industry:

In the pharmaceutical industry, PTFE gaskets are vital for maintaining sterility in production environments. Their properties allow them to withstand sterilization processes without compromising their integrity. A study published in the Journal of Pharmaceutical Sciences notes that PTFE gaskets are recommended for high-purity applications to prevent contamination during drug manufacturing. -

Oil and Gas Industry:

PTFE gaskets protect critical components in the oil and gas industry from extreme temperatures and pressures. They provide sealing solutions for pipelines, pumps, and valves. The American Petroleum Institute highlights the importance of PTFE gaskets in ensuring the safety and reliability of oil transportation networks. The use of PTFE in these applications significantly reduces maintenance costs and down-time.

How Does PTFE Compare to Other Gasket Materials in Performance?

PTFE (Polytetrafluoroethylene) is often compared to various gasket materials based on several performance characteristics. The following table summarizes how PTFE compares to other common gasket materials such as rubber, graphite, and cork:

| Material | Temperature Resistance | Chemical Resistance | Compressibility | Cost | Applications |

|---|---|---|---|---|---|

| PTFE | -200°C to 260°C | Excellent | Low | Medium | Corrosive environments, chemical processing |

| Rubber | -50°C to 120°C | Good (limited) | High | Low | General sealing applications |

| Graphite | -200°C to 450°C | Good | Medium | Medium | High-temperature applications |

| Cork | -30°C to 120°C | Poor | High | Low | Low-pressure applications |

PTFE stands out due to its high-temperature resistance and excellent chemical compatibility, making it suitable for a wide range of applications, especially in corrosive environments. Rubber gaskets are often used for lower temperature applications where compressibility is more critical. Graphite offers decent performance but is not as chemically resistant as PTFE. Cork, while compressible, lacks the temperature and chemical resistance required for many industrial applications.

What Factors Should You Consider When Choosing PTFE for Gaskets?

When choosing PTFE for gaskets, consider factors such as temperature tolerance, chemical compatibility, mechanical properties, surface finish, and industry standards.

- Temperature tolerance

- Chemical compatibility

- Mechanical properties

- Surface finish

- Industry standards

Understanding these factors is crucial for effective gasket performance in various applications.

-

Temperature Tolerance: Temperature tolerance refers to the maximum and minimum temperatures a PTFE gasket can withstand. PTFE gaskets can typically operate within a temperature range of -200°C to 260°C. This range ensures that they maintain their physical integrity and sealing function in extreme environments. For example, in chemical processing industries, machinery often operates at high temperatures. The ability of a PTFE gasket to resist this heat is essential for preventing leaks and ensuring safety.

-

Chemical Compatibility: Chemical compatibility defines how well a PTFE gasket resists deterioration when in contact with various substances. PTFE is known for its high resistance to a broad range of chemicals, including acids, bases, and organic solvents. According to studies, PTFE can withstand more than 90% of all chemicals, making it suitable for use in industries like pharmaceuticals and petrochemicals. However, while PTFE is robust, it is essential to consult compatibility charts to avoid any unexpected reactions.

-

Mechanical Properties: Mechanical properties encompass the strength, elasticity, and compressibility of PTFE. PTFE gaskets should provide a reliable seal under different pressure conditions. These gaskets typically have a high compressive strength, allowing them to maintain their shape under pressure while providing an effective seal. The American Society for Testing and Materials (ASTM) provides guidelines that help assess these mechanical properties to ensure gaskets meet application requirements.

-

Surface Finish: Surface finish refers to the texture and smoothness of the gasket’s surface. A better surface finish can enhance the sealing performance by increasing contact area and reducing leak paths. PTFE gaskets can have various finishes, including textured or polished surfaces. The choice of finish may depend on the specific requirements of the sealing environment, such as vibrations or cleanliness in food and pharmaceutical applications.

-

Industry Standards: Industry standards encompass the regulations and certifications that a PTFE gasket must meet, depending on its application. Standards from organizations such as the FDA (Food and Drug Administration) for food applications or ASME (American Society of Mechanical Engineers) for industrial uses ensure that gaskets meet strict safety and performance requirements. Compliance with these standards is crucial for applications in sectors where safety is paramount.