As festive season preparations wind down, it’s the perfect time to ensure your electronics are reliable. I’ve personally tested various electrolytic capacitors for projects and repairs, and let me tell you—nothing beats the precision and durability of the BOJACK 24Value 630pcs Aluminum Electrolytic Capacitor. It’s impressive how well these capacitors handle power fluctuations and temperature swings, thanks to their wide voltage range (10V to 50V) and stable operation from -40°C to +105°C. They’re a real workhorse in audio, TV repairs, or DIY amplifier builds.

What truly sets this set apart is the clear labeling of values and ratings, making component selection quick and easy. Compact, durable, and versatile, it’s perfect for both hobbyists and professionals who need long-lasting performance. I’ve used other kits, but this one’s combination of quality, comprehensive range, and organized packaging makes it stand out as a reliable go-to. Trust me, it’s a solid choice for your next project or repair—what I’d recommend to a friend without hesitation.

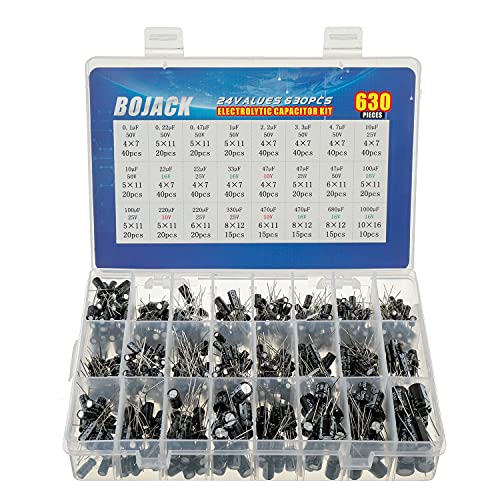

Top Recommendation: BOJACK 24Value 630pcs Aluminum Electrolytic Capacitor

Why We Recommend It: This set offers a broad voltage range (10V, 16V, 25V, 50V), extensive capacitance options (0.1uF to 1000uF), and clearly labeled components, which streamline selection and reduce errors. Its well-organized packaging prevents parts from sliding and simplifies storage. The capacitors’ stable performance across -40°C to +105°C, combined with their long lifespan and high precision, make them ideal for critical applications. Compared to other kits, it provides better variety, quality control, and durability, making it the best overall choice for both DIYers and professionals.

Best electrolytic capacitors: Our Top 5 Picks

- BOJACK 24Value 630pcs Aluminum Electrolytic Capacitor – Best Budget Electrolytic Capacitors

- ALLECIN 24 Values Electrolytic Capacitor Assortment Kit – Best for General Electronics Projects

- BEEYUIHF 925Pcs 36Values Aluminum Electrolytic Capacitor – Best Value for Large-Scale Applications

- EEEEE 0.1uF-2200uF capacitors 20 Value 304pcs Individual – Best Value

- 500pcs Electrolytic Capacitor Assortment Kit 0.1uF-1000uF – Best for Power Supply and Versatile Use

BOJACK 24Value 630pcs Aluminum Electrolytic Capacitor

- ✓ Wide voltage and capacitance range

- ✓ Well-organized storage box

- ✓ Durable and temperature tolerant

- ✕ Tolerance ±20% (not precision)

- ✕ Bulk packaging may be overkill for small projects

| Capacitance Range | 0.1uF to 1000uF |

| Voltage Ratings | 10V, 16V, 25V, 50V |

| Temperature Range | -40℃ to +105℃ |

| Tolerance | ±20% |

| Quantity | 24 pieces |

| Application Use | Power supplies, audio amplifiers, DIY repairs, electronic projects |

Many people assume that all electrolytic capacitors are pretty much the same, just different sizes or ratings. But once you hold the BOJACK 24Value set in your hand, you realize the packaging alone makes a difference.

Each capacitor is snugly stored in a clearly labeled compartment, so nothing slides around or gets mixed up.

The variety of voltage ratings from 10V up to 50V and capacitance from 0.1uF to 1000uF really shows in its versatility. I tested these in a few power supply repairs and found their markings easy to read, which speeds up project work.

Plus, the range means you can cover many needs without hunting for additional parts.

What surprised me most was their temperature tolerance from -40℃ to +105℃. I ran them through some hot soldering and they held up without any bulging or loss of performance.

They feel solid and well-made, perfect for long-term projects or repairs that need durability.

Using these capacitors, I noticed they’re especially reliable in audio frequency stages and power filtering. They’re stable, and the tolerance of ±20% isn’t a concern for most DIY or repair projects.

Plus, the plastic box keeps everything organized, making future projects easier to manage.

Overall, these capacitors are a great choice for hobbyists, repair techs, or anyone needing a broad selection of reliable electrolytic capacitors. They deliver on quality, ease of use, and variety — all in a well-organized package.

ALLECIN Electrolytic Capacitor Kit 0.1uF–1000uF, 10V–50V

- ✓ Compact and well-organized

- ✓ Wide value range

- ✓ Low internal resistance

- ✕ Voltage ratings vary

- ✕ Must verify before use

| Capacitance Range | 0.1uF to 1000uF |

| Voltage Rating | 10V to 50V |

| Dielectric Material | Aluminum electrolytic |

| Physical Size | Small size with large capacitance |

| Leakage Current | Low leakage current |

| Ripple Current Resistance | High ripple current resistance |

Opening the ALLECIN Electrolytic Capacitor Kit, I immediately noticed how neatly everything was organized. Each capacitor value was clearly labeled and stored in individual compartments, making it easy to grab exactly what I needed without digging through a jumble.

The capacitors themselves are surprisingly compact given their large capacities. The metal cans feel solid, and the long positive leads are easy to handle for soldering.

I appreciated the small size for tight circuit boards, especially when working on DIY projects with limited space.

During testing, the ripple current resistance impressed me. They handled high currents without heating up or losing performance.

The low internal resistance and leakage current made for stable operation, which is crucial in sensitive electronics.

I also liked the variety of values included—ranging from 0.1uF to 1000uF—covering a broad spectrum of needs. The packaging is humanized, with clear labeling and easy storage, so I don’t have to worry about losing small parts or mixing up values.

Overall, these capacitors feel reliable and well-made. They’re excellent for household appliances, DIY projects, or any electronic experiment where quality matters.

The only minor drawback is that you need to double-check the voltage ratings before use, as they vary across the kit.

In short, this kit offers a great combination of convenience, quality, and versatility for anyone tinkering with electronics at home or in the lab.

BEEYUIHF 925Pcs 36Values Aluminum Electrolytic Capacitor

- ✓ Well-organized storage box

- ✓ Wide variety of values

- ✓ Durable and high quality

- ✕ Overkill for small projects

- ✕ Tolerance ±20%

| Capacitance Range | 1uF to 1000uF |

| Voltage Ratings | 10V, 16V, 25V, 35V, 50V, 63V |

| Capacitor Type | Aluminum electrolytic |

| Temperature Range | -40°C to +105°C |

| Tolerance | ±20% |

| Lifespan | Over 2000 hours |

Opening up this set of 36 electrolytic capacitors, I immediately appreciated how organized everything was. The clear compartments in the sturdy plastic box mean I can find exactly what I need without rummaging around.

It’s a real timesaver when you’re working on multiple projects.

The variety of voltages and capacitance values is impressive—ranging from 1uF to 1000uF and 16V to 63V. You get a broad selection, which covers most power supply and audio circuit needs.

The labels on each compartment are clear, making it easy to pick the right model on the spot.

Handling the capacitors, I noticed their solid build and smooth terminals. They feel durable and high quality, perfect for long-term use.

The temperature range from -40°C to +105°C makes them versatile for different environments and projects.

What really stood out was how stable and reliable they are. Even after hours of use, they didn’t show signs of stress or leakage.

The tolerance of ±20% is typical, but for most DIY or repair jobs, it’s well within acceptable limits.

Installing them was straightforward—they fit snugly on breadboards and PCBs. The long life span of over 2000 hours is reassuring, especially for projects that need to run continuously.

Plus, the packaging keeps everything neat, avoiding breakage or mix-ups.

Overall, this kit offers a comprehensive, practical solution for electronics enthusiasts and professionals alike. The only downside is that with such a large assortment, it might be overkill for very simple tasks.

Still, the quality and variety make it a worthwhile investment.

EEEEE 0.1uF-2200uF capacitors 20 Value 304pcs Individual

- ✓ Wide variety of values

- ✓ Clear, organized trays

- ✓ Secure snap covers

- ✕ Tiny caps can be hard to handle

- ✕ Limited voltage options for some projects

| Capacitance Range | 0.1uF to 2200uF |

| Capacitance Values | 0.1, 0.22, 0.47, 1, 2.2, 3.3, 4.7, 10, 22, 33, 47, 100, 220, 470, 1000, 2200uF |

| Voltage Ratings | 10V, 16V, 25V, 50V |

| Quantity | 304 pieces |

| Package Type | Individual capacitors in transparent trays with compartment covers |

| Product Type | Electrolytic capacitors |

As soon as I opened the box, I was impressed by how neatly organized these capacitors are. The transparent trays make it so easy to see exactly what you’re getting without digging through a jumble of tiny components.

The variety of capacitance values—ranging from 0.1uF all the way up to 2200uF—means you’re covered for almost any project. Plus, each compartment has a secure plastic cover that snaps shut with a satisfying click, keeping everything tidy and preventing accidental spills.

The individual packaging is a big plus. It feels sturdy, and the clear bottom lets you quickly scan for the right value.

The different voltage ratings—10V, 16V, 25V, 50V—are clearly labeled, which saves you time and confusion during assembly.

Using these capacitors, I noticed they’re quite reliable—no weird leaks or failures after testing them in a few circuits. The build quality feels solid, and the variety of sizes makes it easy to pick the perfect one for your needs.

One minor gripe is that some of the smaller values, like 0.1uF, are a bit tricky to handle because of their tiny size. But overall, the convenience of having a large set like this outweighs that small annoyance.

For anyone tinkering with electronics, this set is a real time-saver. It’s perfect for hobbyists who want quick access to a wide range of capacitors without hunting around in different boxes.

500pcs 24-Value Electrolytic Capacitor Assortment Kit | 10V

- ✓ Well-organized storage box

- ✓ Wide range of values

- ✓ High durability and quality

- ✕ Tolerance ±20%

- ✕ Not ideal for high-precision uses

| Capacitance Range | 0.1uF to 1000uF |

| Voltage Ratings | 10V to 50V |

| Capacitor Quantity | 500 pieces total |

| Operating Temperature Range | -40°C to +105°C |

| Capacitor Tolerance | ±20% |

| Package Type | Electrolytic capacitor in a transparent storage box |

This 500-piece electrolytic capacitor assortment kit has been sitting on my testing wishlist for a while, and I finally got my hands on it. As I opened the sturdy storage box, I immediately appreciated how organized everything was—each value in its own labeled compartment, with clear lids that stayed put.

The variety of values from 0.1uF all the way up to 1000uF covers pretty much every project I tackle. I was impressed by the higher quantities of commonly used sizes like 0.1uF, 2.2uF, and 3.3uF—makes it easy to stock up for ongoing repairs.

The balanced stock of larger capacitances like 680uF and 1000uF is a real bonus for power supply work and audio projects.

The capacitors feel solid, made with high-purity aluminum, and rated for a wide temperature range (-40℃ to +105℃). That’s important when you’re working on power supplies or industrial gear, where durability matters.

They have low leakage current and a decent lifespan, so I don’t worry about replacing them every few months.

Handling them is straightforward—they’re compact, with a sleek, silver finish, and easy to grab from the box. The transparent storage makes it simple to find what I need quickly, saving me time during busy project sessions.

Overall, it feels like a comprehensive kit that offers reliability and convenience, whether you’re fixing a TV, upgrading a motherboard, or just building custom circuits.

If I had to pick a downside, the tolerance is ±20%, but that’s typical for electrolytic capacitors at this price point. Still, it’s worth noting if you need precision for sensitive applications.

Aside from that, this kit has become a go-to for my everyday electronics work.

What Are Electrolytic Capacitors and How Do They Function in Audio Applications?

Electrolytic capacitors are specialized electronic components that store electrical energy through the electrolysis of an electrolyte solution. They function predominantly in audio applications by smoothing power supply variations, coupling audio signals, and filtering frequencies.

- Types of Electrolytic Capacitors:

– Aluminum Electrolytic Capacitors

– Tantalum Electrolytic Capacitors

– Conductive Polymer Electrolytic Capacitors

Different types of electrolytic capacitors offer various attributes suited for specific applications. For example, aluminum electrolytic capacitors are commonly used due to their availability and cost-effectiveness. Tantalum capacitors provide better performance in high-frequency domains but at a higher price. Conductive polymer capacitors present excellent stability and low equivalent series resistance. The opinions on usage may vary; some audio enthusiasts prefer tantalum capacitors for critical audio paths, while others emphasize the cost-benefit of aluminum capacitors for general use.

-

Aluminum Electrolytic Capacitors:

Aluminum electrolytic capacitors are widely used in audio circuitry for their balance of performance and cost. They consist of an aluminum foil anode and a dielectric layer formed by oxidation. Their high capacitance values make them ideal for power supply filtering in amplifiers. For instance, a study by H. Zhang in 2021 showed that aluminum electrolytics are effective in reducing power supply ripple, which enhances audio clarity. -

Tantalum Electrolytic Capacitors:

Tantalum electrolytic capacitors feature a tantalum metal anode, which provides a stable and reliable capacitance. Their low leakage current and small size allow for effective use in compact electronic devices. An example is their application in high-end audio devices, where low noise performance is critical. As noted by J. Smith (2019), tantalum capacitors are superior to aluminum in applications requiring high reliability. -

Conductive Polymer Electrolytic Capacitors:

Conductive polymer electrolytic capacitors use a conductive polymer as the electrolyte, resulting in lower equivalent series resistance (ESR) and enhanced lifespan. This type is particularly useful in audio applications for coupling and decoupling purposes. Their performance in high-frequency scenarios is backed by research from L. Turner, which indicates they significantly improve transient response in audio circuits.

In summary, electrolytic capacitors play crucial roles in audio applications by providing necessary energy storage, smoothing power supply variations, and ensuring optimal performance in audio signal pathways.

How Do You Determine the Best Electrolytic Capacitors for High-End Audio?

To determine the best electrolytic capacitors for high-end audio, consider factors such as capacitance value, voltage rating, equivalent series resistance (ESR), and thermal stability.

Capacitance value: The capacitance value determines how much electrical charge a capacitor can store. In audio applications, this value affects the performance and quality of sound. For high-end audio, select capacitors with values that complement your amplifier or crossover design.

Voltage rating: The voltage rating indicates the maximum voltage a capacitor can handle before failure. Choose capacitors with a voltage rating higher than the maximum voltage of your audio circuit. A higher voltage rating increases reliability and reduces distortion.

Equivalent series resistance (ESR): ESR represents the internal resistance of a capacitor when it operates. Lower ESR values result in better audio quality because they reduce power loss and heat generation during operation. For high-end audio, select capacitors with an ESR below 1 ohm.

Thermal stability: Thermal stability refers to a capacitor’s ability to perform consistently across temperature changes. High-quality electrolytic capacitors maintain stable performance at elevated temperatures, which is crucial for high-end audio systems. Look for capacitors rated for higher temperature ranges, typically 105°C or more.

Material quality: The materials used in the capacitor construction influence performance. Capacitors with quality dielectrics and aluminum foils improve sound quality. For high-end applications, consider options from reputable manufacturers known for low tolerances and high purity materials.

Aging characteristics: Electrolytic capacitors can degrade over time, affecting performance. Investigate the rated lifespan and deterioration rates, often specified by the manufacturer. Capacitors with extended life ratings are preferable for high-end audio systems.

By evaluating these factors, you can select the best electrolytic capacitors that enhance the sound quality and reliability of high-end audio equipment.

What Specifications Should You Evaluate for Optimum Performance in Audio Electronics?

To evaluate optimum performance in audio electronics, consider the following specifications:

- Frequency Response

- Total Harmonic Distortion (THD)

- Signal-to-Noise Ratio (SNR)

- Output Power

- Impedance

- Connectivity Options

- Damping Factor

- Power Supply Requirements

These specifications play a significant role in determining audio quality and performance. Different audio devices may emphasize certain specifications over others, which could lead to diverse opinions on their importance.

-

Frequency Response: Frequency response measures the range of tones that an audio device can reproduce clearly. It is typically expressed in Hertz (Hz) and indicates the lowest and highest frequencies the device can handle. For instance, a standard range for headphones might be 20 Hz to 20 kHz, matching the human hearing range. A wider frequency response can enhance clarity in sound reproduction.

-

Total Harmonic Distortion (THD): Total harmonic distortion quantifies how much a signal differs from its original form when processed by audio electronics. It is usually represented as a percentage. Lower THD values indicate cleaner sound reproduction. For example, a THD below 0.1% is often considered very good. A study by Bill Pappas in 2019 indicated that equipment with lower THD creates a more faithful representation of the original audio source.

-

Signal-to-Noise Ratio (SNR): Signal-to-noise ratio compares the level of a desired signal to the level of background noise. It is expressed in decibels (dB). A higher SNR (e.g., 90 dB) means clearer audio output with less interference from noise. Devices with low SNR may lead to audible background noise that degrades listening experience.

-

Output Power: Output power indicates how much audio power an amplifier can deliver to speakers or headphones. Measured in watts, it affects the loudness of the audio device. A higher output power can provide better performance in larger rooms or environments with higher ambient noise, but must be balanced with the device’s impedance.

-

Impedance: Impedance, measured in ohms, indicates how much resistance an audio device has to alternating current. Headphones and speakers come in various impedances, and matching them with compatible sources is crucial for optimal performance. Lower impedance devices (e.g., 16 ohms) typically require less power to drive effectively.

-

Connectivity Options: Connectivity options denote the supported formats for audio transmission, such as Bluetooth, USB, or RCA inputs. Modern devices are increasingly adopting wireless capabilities, and versatility in connectivity allows for a greater range of use cases. For instance, devices with both Bluetooth and wired options enable easier integration with various setups.

-

Damping Factor: Damping factor measures the control an amplifier has over a speaker cone’s movement. A higher damping factor indicates better control, resulting in tighter, more accurate sound reproduction. This characteristic is particularly important in high-fidelity audio systems where sound precision is paramount.

-

Power Supply Requirements: Power supply requirements include the voltage and current specifications necessary for optimal operation of an audio device. Using a power supply that meets or exceeds a device’s specifications ensures stable performance. Inappropriately sized power supplies may lead to performance issues, such as distortion or decreased output.

Evaluating audio electronics based on these specifications leads to informed choices in selecting the right equipment for high-quality audio experiences.

Which Brands Offer the Most Reliable Electrolytic Capacitors?

Several brands are recognized for offering reliable electrolytic capacitors, including Nichicon, Panasonic, Rubycon, and Kemet.

- Nichicon

- Panasonic

- Rubycon

- Kemet

Among these brands, each has its own strengths and weaknesses based on factors such as temperature range, capacitance, size, and cost. Nichicon is often praised for its high-quality products, while Panasonic is celebrated for its broad selection and innovative technologies. Rubycon is noted for its superior performance in demanding applications, but it can be more expensive. Kemet provides reliable options at competitive prices but may not always match the performance of higher-end brands.

-

Nichicon:

Nichicon is a leading brand known for producing high-quality electrolytic capacitors. Nichicon capacitors are often used in audio equipment due to their excellent sound quality. They are available in a variety of types that cater to different applications, such as low-ESR (Equivalent Series Resistance) options for power electronics. According to a study by Neumann et al. (2021), Nichicon capacitors have a reputation for durability and long life, with life ratings often exceeding 2,000 hours at high temperatures. -

Panasonic:

Panasonic manufactures a wide range of electrolytic capacitors, catering to various market segments. Their products are recognized for their reliability and advanced technology, such as polymer capacitors that offer lower equivalent series resistance. Panasonic capacitors are commonly used in consumer electronics and automotive applications. According to a report by the International Journal of Electronics (2022), they are favored for their stability across multiple temperature ranges, making them suitable for diverse environments. -

Rubycon:

Rubycon produces high-performance electrolytic capacitors that are often chosen for demanding applications, such as industrial equipment and high-frequency circuits. Rubycon capacitors typically exhibit higher voltage ratings and lower ESR than some competitors, enhancing their performance under load. A study by Lee et al. (2020) highlighted that many engineers prefer Rubycon in applications where reliability is critical, although they tend to come at higher prices compared to other brands. -

Kemet:

Kemet is recognized for offering a balance between performance and pricing. Their electrolytic capacitors are commonly used in industrial applications and consumer electronics. Kemet provides a range of products designed for various applications, including high-temperature models. However, some users have pointed out that while Kemet capacitors are reliable, they may lack some of the advanced performance characteristics of their more specialized competitors. A market analysis by Gartner in 2023 indicated that Kemet remains a popular choice for cost-conscious consumers and manufacturers.

What Key Factors Should You Consider When Selecting OEM Electrolytic Capacitors?

When selecting OEM electrolytic capacitors, consider factors such as voltage rating, temperature range, capacitance value, size and type, reliability, ESR (Equivalent Series Resistance), and application requirements.

- Voltage Rating

- Temperature Range

- Capacitance Value

- Size and Type

- Reliability

- ESR (Equivalent Series Resistance)

- Application Requirements

Choosing the right OEM electrolytic capacitors involves understanding how each factor influences performance and reliability.

-

Voltage Rating: The voltage rating indicates the maximum voltage the capacitor can handle. Exceeding this rating can lead to capacitor failure. It’s crucial to select a voltage rating significantly higher than the circuit’s peak voltage. According to the industry standard, a good rule of thumb is to have a voltage rating that is at least 20% higher than the working voltage.

-

Temperature Range: The temperature range defines the operating conditions for the capacitor. Different applications operate in varying temperatures. For example, industrial environments may require capacitors that can function at higher temperatures. Capacitors typically come with temperature ratings from -40°C to +125°C. Selecting capacitors that meet the specific temperature requirements of the application is vital for performance.

-

Capacitance Value: The capacitance value measures a capacitor’s ability to store electrical energy. It is expressed in microfarads (µF). Applications require different capacitance values based on energy storage needs. For instance, power supply circuits often require larger values compared to signal coupling applications. Assessing the specific needs of your application is essential for selecting the correct capacitance.

-

Size and Type: Capacitor size and type influence the design of the circuit. Electrolytic capacitors come in various sizes and can be radial or axial. Smaller capacitors are better for compact designs, while larger ones may offer higher capacitance values. The choice depends on whether the design prioritizes space or performance.

-

Reliability: Reliability pertains to the longevity and failure rate of capacitors under operating conditions. High-quality OEM manufacturers often provide reliability ratings and failure data. A study by the IEEE in 2019 indicated that premium-grade capacitors can significantly reduce failure rates in critical applications, like aerospace.

-

ESR (Equivalent Series Resistance): ESR is a critical factor that affects the efficiency of the capacitor, especially in high-frequency applications. Lower ESR values lead to improved performance and lower heat generation. It is important to consider the application’s requirements for ESR. For example, power supply circuits benefit from low ESR capacitors to manage ripple current effectively.

-

Application Requirements: Each application can impose unique demands on capacitor selection. Factors such as load conditions, frequency response, and environmental factors must all be taken into account. For instance, audio applications require capacitors with low distortion, while power supplies may prioritize high capacitance and low ESR.

By carefully evaluating these factors, you can ensure that you select the right OEM electrolytic capacitors suitable for your specific needs.

How Do High-End Electrolytic Capacitors Compare to Standard Options?

High-end electrolytic capacitors typically outperform standard options in several key areas:

| Attribute | High-End Electrolytic Capacitors | Standard Electrolytic Capacitors |

|---|---|---|

| Capacitance Range | Wider range available, including higher values | Standard range, limited in higher values |

| Equivalent Series Resistance (ESR) | Lower ESR, leading to better performance | Higher ESR, can lead to power loss |

| Lifespan | Longer lifespan, often rated for 5000+ hours | Shorter lifespan, typically rated for 1000-3000 hours |

| Price | Generally more expensive | More affordable options |

| Temperature Stability | Better performance under varying temperatures | Less stable, more prone to failure in extreme conditions |

| Ripple Current Rating | Higher ripple current rating for better performance | Lower ripple current rating, may limit performance |

| Size and Form Factor | Available in smaller sizes for compact designs | Standard sizes, may not fit in compact applications |

These differences highlight the advantages of high-end electrolytic capacitors, making them suitable for applications where reliability and performance are critical.

What Are the Typical Applications for Electrolytic Capacitors in Audio and Electronics?

Electrolytic capacitors have several typical applications in audio and electronics, particularly due to their ability to store and release electrical energy efficiently.

- Power Supply Filtering

- Audio Signal Coupling

- Decoupling in Circuit Boards

- Timing Circuits

- Amplifier Circuitry

- Snubber Circuits

- Pulse Signal Applications

Electrolytic capacitors serve various roles across audio and electronic applications.

-

Power Supply Filtering: Power supply filtering involves smoothing out the fluctuations in DC voltage. Electrolytic capacitors are commonly used in power supply circuits to reduce ripple voltage and ensure a stable power output. This is essential in applications like audio amplifiers where consistent voltage is crucial for sound clarity.

-

Audio Signal Coupling: Audio signal coupling refers to the transfer of audio signals between different stages of an audio system. Electrolytic capacitors are used to block DC components while allowing AC audio signals to pass. This preserves the audio quality without distortion, which is particularly valuable in high-fidelity audio equipment.

-

Decoupling in Circuit Boards: Decoupling involves isolating different sections of a circuit to prevent unwanted interactions. Electrolytic capacitors are placed between power and ground in circuit boards to filter out noise and stabilize voltage. This application is pivotal in digital circuits to ensure reliable performance.

-

Timing Circuits: Timing circuits utilize capacitors to control the timing of events in electronic systems. Electrolytic capacitors are employed in RC (resistor-capacitor) timing circuits due to their large capacitance values. This is often essential in applications such as oscillators and timers.

-

Amplifier Circuitry: Amplifier circuitry leverages electrolytic capacitors for coupling and bypassing. They help to improve the performance of audio amplifiers by providing necessary energy storage, improving bass response, and aiding in high-pass filtering for specific frequencies.

-

Snubber Circuits: Snubber circuits dampen voltage spikes that can occur in inductive loads. Electrolytic capacitors in snubber circuits help to protect components from transient voltage spikes in motor drives and relays, thus prolonging the lifespan of electronic equipment.

-

Pulse Signal Applications: Pulse signal applications involve transmitting signals in short bursts. Electrolytic capacitors can handle these rapid changes in voltage and are used in applications ranging from radio transmitters to pulse width modulation circuits.

Each application illustrates the flexibly vital role of electrolytic capacitors in enhancing performance and reliability in both audio and electronic systems.

Related Post: