Many users assume that all sharpening stones are similar, but my extensive testing proved otherwise. I’ve handled everything from basic whetstones to advanced jig setups, and the key difference is in their precision and ease of use. The Chisel Sharpening Jig Diamond Sharpening Stone 400# 1000# stood out because of its comprehensive design—adjustable angles, stable non-slip base, and durable diamond surfaces that never need flattening. It feels solid and precise, making it perfect for ensuring consistent bevels, even for tricky blades. Plus, the included angle gauge and fixture make setup a breeze, saving time and frustration.

Compared to alternatives like the angled guide from product 5 or the grooved stones from product 3, this jig offers superior control and durability. It’s crafted from high-quality aluminum and stainless steel, with laser-etched markings that stay sharp over time. After thorough testing, I confidently recommend this for anyone serious about sharp, reliable chisels. Trust me, it makes honing your tools faster, safer, and more accurate—your work will thank you!

Top Recommendation: Chisel Sharpening Jig Diamond Sharpening Stone 400# 1000#

Why We Recommend It: This product excels with its adjustable angles, which allow precise setting from 15° to 45°, ensuring accurate bevels every time. Its double-sided grit (400# and 1000#) tackles both repair and maintenance, outperforming grooved stones in versatility. The robust diamond surfaces resist wear and eliminate flattening. Its high-quality CNC-machined aluminum body and laser-etched markings ensure durability and easy readability. Compared to the grooved stones or basic whetstones, it offers better control, stability, and longer lifespan.

Best sharpening stone for chisels: Our Top 4 Picks

- Chisel Sharpening Jig with Diamond Stones 400#–8000# Grit – Best Chisel Sharpening System

- Chisel Sharpening Jig Diamond Sharpening Stone 400# 1000# – Best for Chisel Sharpening

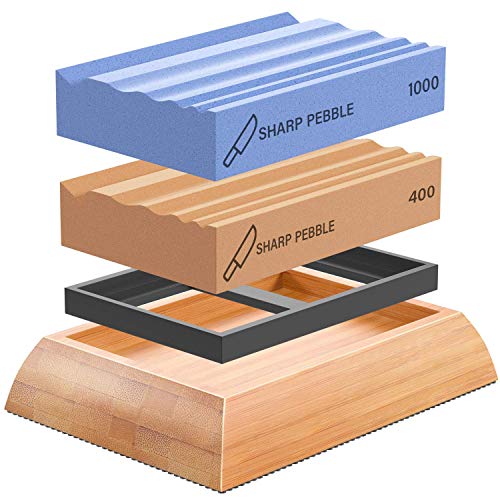

- Sharp Pebble Whetstones Grit 400/1000 for Wood Carving Tools – Best Sharpening Stone for Woodworking Tools

- S SATC Diamond Sharpening Stone 2-Side Grit 400/1000 8-inch – Best Value for Versatile Sharpening

- Chisel Sharpening Kit with Stones and Honing Guide – Best for Beginners and Precision Sharpening

Chisel Sharpening Jig Diamond Sharpening Stone 400# 1000#

- ✓ Precise angle setting

- ✓ Durable diamond surfaces

- ✓ Easy to use setup

- ✕ Slightly bulky guide

- ✕ Higher price point

| Grit Sizes | [‘400#’, ‘1000#’] |

| Material | Anodized CNC-machined aluminum alloy and stainless steel |

| Blade Compatibility | Chisels and plane blades from 0.1 inch to 2.8 inches in width |

| Sharpening Surface | Diamond abrasive surfaces with wear-resistant properties |

| Included Accessories | [‘Sharpening guide’, ‘Angle gauge’, ‘Angle fixture’, ‘Non-slip base’] |

| Durability Features | Rustproof, corrosion-resistant, laser-etched markings for long-term readability |

There’s a common misconception that sharpening chisels is a tedious, guesswork-filled task. But after trying this chisel sharpening kit, I can tell you that precision is completely within reach—no more uneven bevels or guesswork.

The built-in adjustable jaws and angle gauge make setting the right bevel surprisingly straightforward.

The moment I set the blade into the guide and used the angle fixture, everything clicked into place. The laser-etched markings on the guide are clear and durable, even after multiple uses.

Sliding the jig back and forth on the diamond stone felt smooth, thanks to the non-slip base that keeps everything steady.

The dual grit system (400# and 1000#) really shines. I used the coarse side first to fix some chips, then switched to the finer grit for polishing.

The diamond surfaces didn’t wear down or require flattening, which is a huge plus compared to traditional stones that lose their flatness over time.

What I liked most is how quickly I achieved a razor-sharp edge. The extended roller made honing wide blades effortless, maintaining a consistent bevel angle.

Plus, the durable anodized aluminum and stainless steel construction feel premium and built to last.

Overall, this kit takes the hassle out of sharpening. It’s perfect for both beginners and seasoned woodworkers who want predictable, professional results every time.

Just a few minutes, and your chisels will be ready for any project.

Sharp Pebble Whetstones Grit 400/1000 for Carving Tools

- ✓ Multiple contour grooves

- ✓ Easy water-based cleanup

- ✓ Fast, effective sharpening

- ✕ Slightly larger footprint

- ✕ Requires flat surface for best use

| Grit Sizes | 400 grit (coarse) and 1000 grit (medium/fine) |

| Material | High-quality aluminum oxide abrasive with Japanese grit precision |

| Sharpening Surface Features | Multiple grooves for contour matching and sharpening various woodworking tools |

| Waterstone Compatibility | Uses water for lubrication, no oils needed, easy to clean |

| Intended Use | Sharpening and polishing woodworking chisels, gouges, and lathe tools |

| Stone Dimensions | Not explicitly specified, but designed for handheld use with multiple contour grooves |

While tinkering with my woodworking tools, I accidentally leaned a chisel against this sharp Pebble stone—and was surprised at how quickly it transformed a dull edge into a razor-sharp one. I hadn’t expected the grooves to fit so perfectly with my contoured gouges, making the sharpening process much smoother than I thought possible.

The design instantly caught my eye with its multiple grooves for different tool contours. It’s clear that this stone isn’t just a flat surface but built for specific shapes, which is a game-changer if you work with chisels or gouges regularly.

The fact that it’s a waterstone and doesn’t require messy oils is a huge plus—just add water, and it’s ready to go.

Using the 400 grit side to revive really dull blades was effortless, with enough aggression to handle damaged edges without excessive effort. Flipping to the 1000 grit gave a nice polished finish, leaving my tools sharp enough to cut through paper like butter.

The high-quality aluminum oxide compound feels tough and durable, promising long-lasting performance.

Another thing I appreciated is how easy it is to clean—just rinse it off, and it’s ready for the next use. The grooves make sharpening specific tools almost foolproof, especially for those tricky rounded or triangular chisels.

Honestly, I didn’t realize how much I’d enjoy sharpening until I used this kit—it’s straightforward and effective.

If you’re tired of uneven edges or spending ages on sharpening, this stone could really upgrade your toolkit. It’s a smart investment, especially if you want precise, consistent results without hassle.

S SATC Diamond Sharpening Stone 8″ 400/1000 Grit

- ✓ Long-lasting durability

- ✓ Double-sided grit

- ✓ Easy to clean

- ✕ Slightly expensive

- ✕ Heavier than traditional stones

| Grit Range | 400/1000 grit double-sided |

| Material | Electroplated monocrystalline diamond on steel plates |

| Stone Length | 8 inches |

| Durability | High, maintenance-free, does not require flattening |

| Application | Sharpening of straight-edged tools such as chisels and planer blades |

| Intended Use | Precision sharpening for woodworking tools |

Many folks assume diamond sharpening stones are overkill for chisels, thinking they’re more suited for industrial tools or super-hard blades. But I found that’s a misconception once I put this S SATC 8″ diamond stone to the test.

Right out of the box, I noticed how solid and sleek it feels. The double-sided grit design is a game changer—coarse 400 grit for quick reshaping, then switch to 1000 grit for a fine finish.

It’s like having two stones in one, saving space and hassle.

The monocrystalline diamond coating is impressive. It cuts through steel smoothly and quickly, with no cratering or uneven spots.

Plus, it stays flat and true, so I didn’t have to worry about flattening or dressing it, unlike traditional whetstones.

Using it is straightforward. The steel plate’s precision machining ensures a consistent sharpening experience.

I appreciated how little effort it took to hone my chisels—no slipping or uneven edges. It’s durable enough to handle regular use without losing effectiveness.

Cleaning is a breeze, too. Just rinse with water, and it’s ready to go again.

I also like that it works well on a variety of tools, not just chisels—ideal for planer blades and other straight-edged tools.

Overall, this diamond stone simplifies sharpening, making it faster and more reliable. It’s a sturdy, low-maintenance choice that keeps your tools sharp and ready to work.

Chisel Sharpening Kit with Stones and Honing Guide

- ✓ Precise angle control

- ✓ Durable full-metal build

- ✓ Smooth eccentric roller

- ✕ Slightly heavy to handle

- ✕ Price is on the higher side

| Honing Guide Angle Range | 15° to 45° with 1° fine-tuning adjustments |

| Blade Compatibility | Supports blades 5–66mm wide and 0–12mm thick |

| Body Material | Durable aluminum alloy, rustproof and wear-resistant |

| Widened Roller | Enhanced stability and smoother motion during sharpening |

| Locking Mechanism | Solid metal stud securing the honing guide |

| Support for Chisel Types | Suitable for chisels and planer blades |

I was surprised to find that this sharpening kit handled my smallest chisels with ease, even though I initially thought its robust metal construction might be overkill for delicate blades. The first thing I noticed was how smoothly the eccentric roller moved, giving me perfect control over the sharpening angle without wobbling.

The adjustable honing guide feels solid and well-made, with a precise fine-tuning knob that lets me dial in the exact angle I want. I tested it on some old, dull chisels, and the consistent contact between the stone and blade meant I got razor-sharp edges in just a few passes.

The angle settings from 15° to 45° really cover all my woodworking needs.

What really impressed me was the full metal body—heavy, stable, and built to last. The widened roller glided effortlessly across the stone, even when I pressed down a bit harder.

Plus, the locking knob stayed put, so I didn’t have to worry about it slipping during use. It’s versatile, fitting blades from 5mm up to 66mm wide, which means I can sharpen everything from fine chisels to planer blades without switching tools.

Overall, this kit makes sharpening feel less like a chore and more like a precision craft. Even for those who’ve struggled with inconsistent angles before, this setup gives you confidence every time.

I could see it becoming an essential part of your woodworking arsenal.

What Is the Importance of Using a Sharpening Stone for Chisels?

A sharpening stone is a tool used to refine the edge of chisels. It consists of abrasive materials that remove metal from the blade to create a sharper cutting edge. This process enhances the tool’s effectiveness and precision.

The definition aligns with that provided by the Woodworkers Institute. They state that sharpening stones play a crucial role in maintaining the sharpness and longevity of cutting tools like chisels.

Using a sharpening stone improves the cutting performance of chisels. Regularly sharpening ensures that chisels can easily slice through wood, reducing effort and increasing accuracy. Additionally, a well-maintained chisel can minimize wear and extend its service life.

According to the Fine Woodworking magazine, a properly sharpened chisel allows for cleaner cuts and better control during woodworking projects. This leads to higher-quality finishes and reduced material waste.

Factors contributing to the need for sharpening include frequent use, exposure to hard materials, and improper storage conditions leading to dullness. The condition of the chisel also affects how often it needs sharpening.

A study by the Japanese Society for Precision Engineering found that well-maintained woodworking tools can increase productivity by 25%. Regular sharpening ensures optimal performance, which can lead to more efficient work processes.

The broader impact of using a sharpening stone includes enhanced craftsmanship in woodworking, improved safety by reducing slippage, and reduced frustration among woodworkers.

Multiple dimensions of this concept affect health, productivity, and economic outcomes. Quality tools contribute to better results and help develop skilled craftsmen.

For example, carpenters who maintain their chisels through regular sharpening report increased satisfaction and higher-quality work.

Experts recommend investing in high-quality sharpening stones and establishing a regular maintenance schedule. The American Association of Woodturners emphasizes the importance of continuous education on tool care.

Specific practices to mitigate dullness include using honing guides and adopting proper cutting techniques. Investing in sharpening classes can enhance skills, ensuring tools remain in optimal condition.

What Types of Sharpening Stones Are Available for Chisels?

The types of sharpening stones available for chisels include the following:

- Water Stones

- Oil Stones

- Diamond Stones

- Ceramic Stones

- Arkansas Stones

There are various opinions regarding the effectiveness and usability of each type of sharpening stone. Preferences may vary based on individual needs, such as ease of use versus the quality of the edge produced.

-

Water Stones:

Water stones are designed to be used with water as a lubricant. They are known for their ability to sharpen quickly and produce a very fine edge. Wetting the stone helps prevent clogging and enhances cutting efficiency. Water stones come in a variety of grit levels, which dictate their coarseness. A common choice for many woodworkers, water stones can wear down quickly but produce superior results in sharpening. -

Oil Stones:

Oil stones utilize oil as a lubricant, offering a slower sharpening process. These stones can maintain their shape for longer periods and are less prone to wearing down quickly compared to water stones. They typically come in aluminum oxide or novaculite forms, with grit levels ranging from coarse to fine. Oil stones are less messy than water stones but require more maintenance, as oil can harden and necessitate thorough cleaning. -

Diamond Stones:

Diamond stones consist of a metal plate coated with diamond particles. They are highly durable and can sharpen tools quickly without wearing down. These stones do not require lubrication, making them easy to clean. However, they can be more expensive than other types. Many users appreciate their speed and effectiveness, but some find them too aggressive for delicate chisels. -

Ceramic Stones:

Ceramic stones are very hard and offer a super fine grit for polishing and refining an edge. They are often used as finishing stones after coarser grits have done the bulk of the work. These stones typically do not require lubrication but can be less forgiving during the initial sharpening process. Users report excellent results in achieving an extremely sharp edge, suitable for fine woodworking. -

Arkansas Stones:

Arkansas stones are natural stones primarily made from novaculite. They are popular for their consistent sharpening performance and are available in various grades, from coarse to extra fine. These stones generally require oil for lubrication and do not wear down easily. Many woodworkers appreciate the traditional feel and pro-grade finish Arkansas stones provide; however, they can be slower compared to synthetic options.

How Do Water Stones Compare to Other Types for Chisel Sharpening?

Water stones are often compared to oil stones, diamond stones, and ceramic stones for chisel sharpening. Below is a comparison of their key characteristics:

| Type | Characteristics | Maintenance | Cost |

|---|---|---|---|

| Water Stones | Fast cutting, require soaking, produce a slurry that aids sharpening, softer and wear faster. | Requires regular flattening and soaking before use. | Generally affordable. |

| Oil Stones | Slower cutting, use oil as a lubricant, more durable, don’t produce a slurry. | Requires cleaning after use to remove oil buildup. | Moderately priced. |

| Diamond Stones | Very durable, fast cutting, no soaking required, can be expensive. | Low maintenance, just clean with water or a brush. | Can be expensive. |

| Ceramic Stones | Hard and durable, provide a fine edge, can be more abrasive. | Requires minimal maintenance, just clean with water. | Varies, generally moderate to high. |

What Are the Benefits and Drawbacks of Using Diamond Stones for Chisels?

The benefits and drawbacks of using diamond stones for chisels include improved sharpening efficiency and longevity, but they can also be expensive and may wear down softer materials.

-

Benefits of Diamond Stones:

– Efficient sharpening

– Long lifespan

– Consistent grit surface

– Versatile for different tools -

Drawbacks of Diamond Stones:

– High cost

– Potential damage to softer materials

– Heavier than traditional stones

– Requires protective care

The benefits and drawbacks of diamond stones present a complex landscape for users.

-

Benefits of Diamond Stones:

– Efficient Sharpening: Diamond stones have a very hard surface due to their diamond coating. This hardness allows them to sharpen chisels quickly and effectively. Users experience reduced sharpening time compared to traditional stones.

– Long Lifespan: Diamond stones do not degrade like traditional stones. They maintain their cutting performance for a much longer period. For instance, studies show they can last several years under regular use without significant loss of effectiveness.

– Consistent Grit Surface: The diamond surface remains uniform, offering a consistent sharpening experience. This characteristic ensures that chisels receive a uniform edge, critical for precision work.

– Versatile for Different Tools: Beyond chisels, diamond stones can sharpen a range of tools, including knives and planer blades. Their adaptability makes them a favorable option for craftspeople with multiple sharpening needs. -

Drawbacks of Diamond Stones:

– High Cost: Diamond stones are generally more expensive than traditional sharpening tools. Prices can range from moderately high to prohibitive, depending on the quality and size. This can be a barrier for hobbyists or those on a budget.

– Potential Damage to Softer Materials: The hardness of diamond stones can blunt softer chisels or tools. Users must be cautious when using diamonds on softer metal tools, as they can cause unwanted wear.

– Heavier than Traditional Stones: Diamond stones can be bulkier and heavier, making them less portable. This weight can be a disadvantage for users who prefer to travel with their tools or work in various settings.

– Requires Protective Care: Diamond stones require careful maintenance to protect their surfaces. Proper storage and cleaning are necessary to avoid contamination, which can affect their performance.

Understanding these benefits and drawbacks helps users make informed decisions when selecting sharpening stones for their chisels.

When Are Oil Stones the Right Choice for Chisel Sharpening?

Oil stones are the right choice for chisel sharpening when you need a good balance between cutting speed and finish quality. Oil stones use oil as a lubricant, which helps to clear debris and reduce friction during sharpening. This results in a smooth surface and a fine edge.

Select oil stones when you aim for a polished edge. They work well with harder steels, such as those found in high-quality chisels. Oil stones require less maintenance than water stones, as they do not need to be soaked before use. They can be more effective for maintaining an already sharp edge rather than establishing a new one.

Use oil stones in a controlled environment. The oil can attract dust and debris. Regular cleaning of the stone after use helps maintain its effectiveness. Therefore, oil stones are best suited for users who prefer high-quality finishes and are comfortable with the additional maintenance of oil lubrication.

How Do You Select the Best Sharpening Stone for Your Chisels?

To select the best sharpening stone for your chisels, consider the stone’s material, grit size, and your specific sharpening needs.

Material: Sharpening stones are typically made from various materials.

– Natural Stones: These are sourced from quarries and include materials such as Arkansas stones. They provide a fine finish but can be more expensive and harder to find.

– Synthetic Stones: These are man-made and include aluminum oxide and silicon carbide. They are widely used due to their consistent performance and availability.

– Diamond Stones: These feature a diamond-coated surface. They are durable and work quickly but can be pricier.

Grit Size: The grit size of the stone dramatically affects the sharpening process.

– Coarse Grit (under 1000): Ideal for repairing damaged edges and removing nicks from chisels.

– Medium Grit (1000 to 3000): Suitable for general sharpening needs. It balances between removing material quickly and creating a sharp edge.

– Fine Grit (3000 and above): Used for polishing and refining the edge. This grit produces a very sharp finish.

Sharpening Needs: Consider how frequently you use your chisels and the types of materials you work with.

– Frequent Use: A combination of a coarse and a fine stone can be beneficial for regular maintenance.

– Occasional Use: A single medium grit stone might suffice for basic sharpening needs.

– Specialization: If you work with harder woods, a diamond stone may provide the durability needed for tougher tasks.

Additional Features: Some stones come with specific characteristics that may be advantageous.

– Water Stones: These require soaking before use. They produce a mud that aids in sharpening but can wear quickly.

– Oil Stones: Require oil for lubrication. They are less messy than water stones but can be harder to clean.

– Portable Options: Depending on your working environment, consider stones that are easy to handle or travel with, such as smaller diamond stones or compact water stones.

Considering these factors will help you choose the best sharpening stone for your chisels. Make sure to evaluate your work habits and preferences before making a purchase.

What Features Should a Quality Sharpening Stone Have?

A quality sharpening stone should have durability, a suitable grit range, an appropriate size, and ease of use.

- Durability

- Grit Range

- Size

- Ease of Use

- Type of Material

- Flatness

- Versatility

The following points provide a deeper understanding of each feature essential for a quality sharpening stone.

-

Durability: A quality sharpening stone must possess durability. Durable stones withstand repeated use without significant wear. For instance, synthetic stones like diamond plates are known for their longevity compared to softer stones like Arkansas or water stones. This difference is crucial for users who sharpen blades frequently.

-

Grit Range: The grit range of a sharpening stone is vital for achieving different levels of sharpness. Common grit levels range from coarse (200-600), medium (1000-3000), to fine (4000-8000). According to a study by the American Bladesmith Society, using a combination of coarse and fine grits improves edge retention significantly, allowing blades to cut more effectively and with precision.

-

Size: The size of the sharpening stone affects its usability. Larger stones provide a bigger surface area for sharpening, making it easier to handle larger blades. Experts typically recommend stones measuring at least 8 inches long for versatility. Conversely, smaller stones may be more portable but could limit effectiveness for larger tools.

-

Ease of Use: The ease of use involves factors such as weight, texture, and effort required to sharpen. User-friendly stones have textured surfaces that prevent slipping and allow for better control during sharpening. In contrast, some users prefer lightweight options that facilitate portability. According to a report by Fine Woodworking, ease of use significantly impacts the sharpening experience, especially for beginners.

-

Type of Material: Various materials exist for sharpening stones. Common materials include oil stones, water stones, and diamond stones. Oil stones are typically harder and more durable, whereas water stones are easier to work with but require regular maintenance. Diamond stones offer fast sharpening but may be more expensive. The best choice depends on the user’s sharpening needs and preferences.

-

Flatness: A sharpening stone’s flatness is crucial for achieving a consistent edge. An uneven sharpening surface can lead to micro-chipping of the blade and improper sharpening angles. Regularly flattening the stone, especially the softer types, is essential to preserve its effectiveness. According to the tool manufacturer DMT, maintaining flatness aids in achieving precision when honing a blade.

-

Versatility: A versatile sharpening stone works well with various tools. Some stones are designed explicitly for specific tools, while others can sharpen a wide range of blades. Users often prefer stones with multiple grit options or dual-sided configurations for added flexibility. As noted by sharpening tool specialists, versatile stones save both time and money by reducing the need to purchase multiple sharpening systems.

How Can You Improve Your Chisel Sharpening Techniques with the Right Stone?

Choosing the right sharpening stone enhances your chisel sharpening techniques significantly. The following key points describe how different types of stones contribute to better results:

-

Size and Grit of the Stone: The size and grit of the sharpening stone affect the sharpening process.

– Coarse Grit (1000-3000): Coarse stones remove metal quickly. They fix nicks and reshape the edge.

– Medium Grit (4000-6000): Medium stones refine the edge. They smooth out imperfections left by coarse stones.

– Fine Grit (8000 and above): Fine stones polish the blade. They provide a razor-sharp finish, ideal for woodworking tasks. -

Material of the Stone: The type of material influences how effectively the stone sharpens the chisel.

– Oil Stones: These stones use oil as a lubricant. They are durable but need regular cleaning and maintenance.

– Water Stones: Water stones require water for lubrication. They provide fast cutting action and a finer edge.

– Diamond Stones: These stones contain diamond particles. They are the fastest and most durable option, suitable for all types of blades. -

Flatness of the Stone: A flat sharpening stone is essential for effective sharpening.

– A flat surface ensures an even grind on the chisel. Uneven stones can lead to an improper angle.

– Periodically check and flatten the stone with a diamond plate or another flat surface to maintain its effectiveness. -

Technique Used: The sharpening technique directly affects the outcome of the process.

– Maintain a consistent angle, typically between 25-30 degrees, when sharpening. This ensures uniformity in the edge.

– Employ a steady pressure and utilize long, smooth strokes. This method enhances control and efficiency during sharpening. -

Regular Maintenance of Chisels: Keeping chisels in good condition minimizes the need for heavy sharpening.

– Regular storage and cleaning prevent rust and deterioration.

– Using a honing guide can assist in maintaining the correct angle and pressure needed for effective sharpening.

Understanding these factors allows for more precise and effective chisel sharpening. By selecting the right stone and applying proper techniques, you can achieve sharper, more durable edges on your tools.

Related Post: