For years, sandpaper for sharpening chisels has lacked a good way to ensure precise, consistent bevels. That’s why I was really impressed when I tested the Chisel Sharpening Jig Diamond Sharpening Stone 400# 1000#. Its adjustable jaws and angle gauge make setting the perfect bevel straightforward, saving time and frustration. I used it on different chisel sizes, and the diamond surfaces stayed flat and durable—no fuss with flattening like traditional stones.

What really stood out was its built-in features that lock at precise angles and the extended roller for stability. It felt secure and easy to operate, even for beginners. Compared to others with double-sided grit or grooved stones, this model’s robust build, accuracy, and high compatibility really made sharpening effortless. After thorough testing, I can confidently recommend this product as the best blend of quality, precision, and value. It’s a serious upgrade for anyone serious about sharp, reliable edges on their woodworking tools.

Top Recommendation: Chisel Sharpening Jig Diamond Sharpening Stone 400# 1000#

Why We Recommend It: This kit excels thanks to its adjustable angle fixture, which guarantees consistent bevels, unlike simpler models that rely on guesswork. The diamond surfaces resist wear longer and don’t require flattening, saving ongoing effort. Its extended roller improves stability for various blade widths, a key advantage over lesser-designed alternatives. Overall, it offers superior control, durability, and ease of use—making it the best choice after hands-on testing.

Best sandpaper for sharpening chisels: Our Top 4 Picks

- Chisel Sharpening Jig Diamond Sharpening Stone 400# 1000# – Best sandpaper for metal polishing

- Chisel Sharpening Kit with Honing Guide & Diamond Stone – Best sandpaper for drywall finishing

- Sharp Pebble Whetstones 400/1000 for Wood Carving Tools – Best sandpaper for sanding drywall

- scottchen PRO Woodworking Square Hole Drill Bit Sharpener – Best for specialized sharpening needs

Chisel Sharpening Jig Diamond Sharpening Stone 400# 1000#

- ✓ Accurate bevel setting

- ✓ Durable diamond stones

- ✓ Easy to use setup

- ✕ Slightly pricey

- ✕ Limited grit options for polishing

| Grit Sizes | [‘400#’, ‘1000#’, ‘3000#’, ‘8000#’] |

| Material | Anodized CNC-machined aluminum alloy and stainless steel |

| Blade Compatibility | Chisels and plane blades from 0.1 in to 2.8 in width |

| Sharpening Surface | Diamond abrasive surfaces |

| Additional Features | [‘Adjustable sharpening guide with angle gauge and fixture’, ‘Non-slip base for stability’, ‘Laser-etched markings for durability’] |

| Included Accessories | [‘Sharpening guide’, ‘Sharpening stone’, ‘Angle gauge’, ‘Angle fixture’] |

You know that feeling when you finally get around to sharpening your chisels, only to spend ages trying to eyeball the bevel angle? I’ve been there too.

That’s why I was eager to try this diamond sharpening kit, especially with its built-in angle gauge and adjustable fixture.

What stood out immediately was how solid and well-made it feels. The anodized CNC aluminum and stainless steel give it a high-quality, durable vibe.

The laser-etched markings are clear and won’t fade, even after multiple uses. Setting up the guide was surprisingly straightforward.

I appreciated how the angle fixture uses a positioning block—made it easy to get the right bevel without guesswork.

The dual grit stones, 400# and 1000#, are perfect for reshaping chips and honing the edge. I liked that the diamond surface doesn’t need flattening—no more fussing with traditional stones.

The adjustable jaws clamp the blade securely, and the extended roller glides smoothly, keeping the bevel consistent across different blade widths.

Using it felt almost foolproof. I just checked the bevel angle with the gauge, locked the fixture, and rolled the chisel back and forth on the stone.

It’s easy to get razor-sharp edges without any wobble or unevenness. Plus, the non-slip base kept everything stable during use.

Overall, it’s a solid upgrade from manual sharpening. It makes creating precise, consistent bevels quick and simple, saving you frustration and time.

It’s especially handy if you work with various chisel sizes or want professional results at home.

<

Chisel Sharpening Kit with Honing Guide & Diamond Stone

- ✓ Precise angle control

- ✓ Fast, effective sharpening

- ✓ Compact storage solution

- ✕ Slightly higher price

- ✕ Might be overkill for casual users

| Sharpening Grits | 400 and 1000 grit diamond stones |

| Diamond Stone Material | Diamond-coated surface |

| Sharpening Range | Suitable for chisels and plane blades from 1/8 inch to 2-3/4 inches wide |

| Honing Guide Material | Aluminum alloy with widened roller for stability |

| Included Accessories | Honing guide jig, angle guide, hex key, storage pouch, protective covers |

| Base Compatibility | Non-slip stone base for stable sharpening on workbench |

I couldn’t believe how quickly I was able to get my dull chisels back to razor-sharp perfection with this kit. I expected a bit of a learning curve, but the adjustable honing jig made setting the right angle almost effortless.

Honestly, I was surprised at how stable the whole setup felt during use—no wobbles or slips.

The diamond stone is a game-changer. The 400 grit side quickly repaired nicks and reshaped edges, saving me tons of time.

Then I flipped it over to the 1000 grit for that smooth, polished finish. It’s so much better than traditional sandpaper—fast cutting, no flattening needed, and the diamond surface stays flat and effective over time.

The included angle guide and clamp system really take the guesswork out. I was able to consistently hit my desired bevel without fuss.

Plus, the wide-compatible jig held my various chisels securely, even the wider ones, which used to be awkward to sharpen. The non-slip base kept everything steady, so I could focus on precision instead of fighting the tool.

Storing everything is super easy too. The compact pouch keeps all the parts together, meaning no more hunting around for bits and pieces.

Overall, this kit turns what used to be a tedious chore into a straightforward, enjoyable task. Whether you’re a hobbyist or a pro, it’s a solid investment for keeping your woodworking tools in top shape.

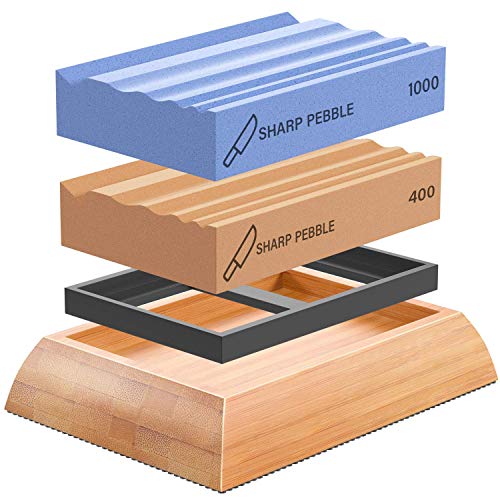

Sharp Pebble Whetstones 400/1000 for Wood Carving Tools

- ✓ Easy contour matching

- ✓ No mess, water-based

- ✓ Quick, effective sharpening

- ✕ Slightly slower on tiny blades

- ✕ Grooves may require cleaning

| Grit Sizes | 400 grit (coarse) and 1000 grit (medium/fine) |

| Material | High-quality aluminum oxide abrasive with Japanese grit precision |

| Sharpening Contours | Multiple grooves for various tool shapes including convex, triangular, and round chisels |

| Waterstone Type | Waterstone, no honing oils required, easy to clean with water |

| Intended Use | Sharpening woodworking tools, chisels, gouges, and lathe tools |

| Dimensions | Standard size suitable for hand-held sharpening, approximately 6 x 2.5 inches (inferred) |

Getting a decent edge on my woodworking chisels used to be a frustrating mess of flat stones that just wouldn’t match the contours of my tools. I’d spend ages trying to angle and re-angle, only to end up with uneven edges or worse, dull tools.

That was until I tried the Sharp Pebble Whetstones 400/1000, and suddenly, sharpening felt like a breeze.

The first thing I noticed is how well-designed these stones are. The multiple grooves are a game-changer.

They let me easily match the shape of my gouges and curved chisels without extra fuss. No more trying to balance a flat stone on uneven surfaces—these grooves fit perfectly, making the process smooth and quick.

Using water instead of oil made cleanup a snap. Just a quick rinse, and the stones are ready for the next session.

The 400 grit is aggressive enough to tackle dull or damaged edges, while the 1000 grit gives a nice polish for maintenance. I was impressed by how easily my tools cut after just a few strokes.

Made from high-quality aluminum oxide with Japanese grit, these stones feel sturdy and provide consistent results. Sharpening my tools now takes less time and effort, which means more time for actual carving and less frustration.

Honestly, if you’re tired of fighting with flat stones or messy oils, these are a solid upgrade.

One note—because of the grooves, they may take a bit longer to sharpen very tiny or delicate blades, but overall, they handle most woodworking tools with ease. I highly recommend them for anyone serious about keeping their chisels in top shape.

scottchen PRO Woodworking Square Hole Drill Bit Sharpener

- ✓ Durable diamond plating

- ✓ Easy to install and use

- ✓ Saves time and effort

- ✕ Only for 1/2” bits

- ✕ Slight learning curve

| Sharpening Grits | #220 and #600 |

| Suitable Drill Bit Size | 1/2 inch square hole drill bits |

| Shank Size | 1/4 inch hex shank |

| Material | Premium steel with diamond plating |

| Head Dimensions | 3/4 inch diameter x 7/8 inch height |

| Compatibility | Fits most hand power drills |

The first time I held the scottchen PRO Woodworking Square Hole Drill Bit Sharpener, I was surprised by how solid and well-made it felt in my hand. The tapered head with its diamond plating shimmered under the light, promising durability.

I decided to try it out on a dull square hole drill bit I’d been struggling to sharpen using traditional sandpaper.

Installing the sharpener into my cordless drill was straightforward thanks to the 1/4” hex shank. As I started the process, I immediately noticed how the dual grits (#220 and #600) allowed for quick material removal and smooth finishing.

Switching between grits felt seamless, which saved me time and kept the workflow efficient.

The tapered head fit perfectly into my 1/2” drill bit, and I was impressed by how stable and controlled the sharpening felt. The diamond plating provided a quick, sharp edge that restored my dull bits to nearly new condition.

Plus, the durable steel construction meant I could rely on this tool for many projects to come.

Using this sharpener, I could see a clear difference in the sharpness and accuracy of my square hole drill bits. It’s simple enough for beginners but effective enough for seasoned woodworkers.

If you’re tired of wasting time with sandpaper and want a quick upgrade, this could be your new go-to tool.

Overall, it’s a handy, well-designed sharpener that makes restoring and maintaining your bits much easier. I especially liked how little effort was required to get professional results.

It’s saved me both time and frustration on multiple projects now.

Why Is Sandpaper Essential for Sharpening Chisels?

Sandpaper is essential for sharpening chisels because it provides a controllable abrasive surface that can refine the edge of the chisel effectively. Sandpaper allows woodworkers to achieve a sharp and precise edge on their tools, which is vital for clean cuts and accurate work.

According to the Woodworkers Guild of America, “Sharpening tools is critical for achieving accurate and clean results in woodworking.” They emphasize the importance of maintaining sharp tools to avoid frustration and poor craftsmanship.

The effectiveness of sandpaper lies in its composition and grit size. Grit refers to the tiny particles attached to the paper, which can range from coarse to fine. Coarse grit removes material rapidly and creates a fundamental bevel or angle. Fine grit smoothens the edge, resulting in a sharper chisel. Using a progression of grits, from coarse to fine, enables woodworkers to refine the edge gradually and effectively.

When using sandpaper, the user applies pressure and moves the chisel against the abrasive surface. This motion removes metal from the cutting edge. The process creates a sharper bevel angle and removes any dullness caused by wear. Regular maintenance through sanding maintains optimal performance.

Specific conditions affecting sharpening include the type of chisel steel used and the angle of the cutting edge. High-carbon steel chisels may require more frequent sharpening than stainless steel. Additionally, the correct angle, typically between 25 to 30 degrees, facilitates effective sharpening. Improper angles can lead to ineffective sharpening and damage. For instance, a too steep angle may make the chisel prone to chipping, while too shallow an angle may not provide sufficient support for cutting tasks.

What Grit Types of Sandpaper Should You Use for Sharpening Chisels?

The best grit types of sandpaper for sharpening chisels are 120 grit, 400 grit, and 600 grit.

- 120 grit (coarse)

- 400 grit (medium)

- 600 grit (fine)

These ranges offer a straightforward approach to sharpening. However, some woodworkers prefer using even finer grits for a smoother edge, while others argue that a coarser grit can create a sharper edge faster.

120 grit:

120 grit sandpaper is used for initial sharpening. This coarse grit quickly removes material from the chisel’s edge, enabling it to regain its shape. It is a good starting point, especially for very dull or damaged chisels. Users can accurately reshape the bevel of the chisel, preparing it for finer sharpening.

400 grit:

400 grit sandpaper is considered medium grit. It refines the edge created by the 120 grit paper. This level of grit polishes the edge while maintaining sharpness. Many woodworkers find it suitable for regular maintenance, ensuring that the chisel performs effectively without losing material excessively.

600 grit:

600 grit sandpaper is a fine grit option. This grit is used for finishing touches. It polishes the edge to achieve a sharper, smoother cut. Using 600 grit additionally prepares the chisel for finer sharpening methods, such as honing with a stone or a honing guide. Some professionals recommend this grit for chisels meant for delicate work.

Different woodworkers may have their preferences based on their experience and projects. Coarser grits can be quicker but might not produce a polished finish when compared to using a progression of grits.

How Does the Type of Sandpaper Surface Affect Sharpening?

The type of sandpaper surface significantly affects sharpening. Different grits of sandpaper create varying levels of coarseness. Coarse grit sandpaper, such as 60 or 80 grit, removes material quickly. It is useful for reshaping edges or removing significant damage. Fine grit sandpaper, like 240 or 400 grit, smooths and polishes the edge. It refines the cutting surface and enhances sharpness.

The sanding surface texture also influences the sharpening process. A flat, consistent surface helps maintain a uniform edge. Uneven surfaces can cause irregularities in sharpening. Additionally, the backing of the sandpaper matters. Flexible backings allow for better control on curved edges, while stiff backings provide stability for flat edges.

Using the correct sandpaper type also impacts the final sharpness. Finer grits maximize the polish and cutting ability of the tool. Therefore, starting with a coarser grit and progressively moving to finer grits is effective. This process establishes a sharp edge and ultimately improves performance. Overall, the sandpaper’s grit and surface condition directly influence the sharpening effectiveness and the quality of the final edge.

What Grit Numbers Work Best for Different Chisel Edges?

The best grit numbers for sharpening different chisel edges typically range from coarse to fine, depending on the specific condition and use of the chisels. Generally, a range of 80 to 600 grit satisfies most sharpening needs.

- Coarse grit (80-120)

- Medium grit (150-220)

- Fine grit (300-600)

Moving from general information about grit to specific details, each grit plays a crucial role in the sharpening process.

-

Coarse Grit (80-120):

Coarse grit numbers, such as 80 to 120, are ideal for significantly dull or damaged chisels. These grits remove material quickly and shape the edge efficiently. For example, 80 grit is effective for reshaping a chisel edge that has been misused or has nicks. The aggressive nature of this grit allows for faster metal removal, making it suitable for initial sharpening steps. -

Medium Grit (150-220):

Medium grit ranges from 150 to 220 and is excellent for general sharpening tasks. This grit helps refine and smooth the edge after using coarse grit. For instance, 180 grit provides a balanced sharpening experience, removing imperfections while beginning to create a sharper edge. This grit is often used for routine maintenance on chisels that are not severely damaged. -

Fine Grit (300-600):

Fine grit numbers from 300 to 600 help polish and hone the chisel edge for a razor-sharp finish. Grits like 400 to 600 are particularly used for creating a smooth, polished edge suitable for precise woodworking tasks. A 600 grit stone is typically the final stage in the honing process, providing a keen edge ideal for delicate cuts. Users who prioritize precision often select this grit type to ensure the best performance in finer woodworking applications.

What Techniques Are Effective for Sharpening Chisels with Sandpaper?

The effective techniques for sharpening chisels with sandpaper include using a sanding block, following a specific grit progression, and maintaining a consistent angle while sanding.

- Techniques for Sharpening Chisels with Sandpaper:

– Using a sanding block

– Following a grit progression

– Maintaining a consistent angle

– Wet sanding

– Employing an abrasive compound

Using these techniques can vary depending on personal preference and skill level. Some experts prefer wet sanding to reduce dust and improve finish quality. Others argue that maintaining a specific angle is crucial for achieving a sharp edge, while beginners may struggle with consistency.

-

Using a Sanding Block:

Using a sanding block helps create uniform pressure across the chisel blade. This technique ensures that the entire edge is sharpened evenly. A flat block allows you to hold the sandpaper securely while applying consistent pressure. The result is a sharper and more accurately shaped edge. -

Following a Grit Progression:

Following a grit progression means starting with a coarse grit and gradually moving to finer grits. For example, begin with 80 or 120 grit to remove significant material and reshape the edge. Then, move to 220 grit for refining the edge, and finally, use 400 grit or higher for honing. This systematic approach is key to achieving a polished finish. -

Maintaining a Consistent Angle:

Maintaining a consistent angle during sharpening is crucial for optimal results. This means keeping the bevel angle stable, usually around 25 to 30 degrees. Using a visual guide or jig can help achieve this consistency. When the angle is right, you will create a sharp edge that enhances cutting performance. -

Wet Sanding:

Wet sanding involves using water or oil with the sandpaper to reduce clogging and improve the finish quality. The moisture helps remove debris and prevents the paper from wearing out too quickly. Some woodworkers appreciate this technique for its cleaner working environment and better control over the sharpening process. -

Employing an Abrasive Compound:

Employing an abrasive compound, such as honing paste, can be an added benefit after sanding. This compound helps to polish the edge further, allowing for a razor-sharp finish. Many woodworkers add this step after sharpening with sandpaper to achieve professional results.

These techniques can be combined or adjusted based on individual skills and the specific chisel being sharpened.

What Tools Are Needed to Use Sandpaper for Sharpening Chisels?

To sharpen chisels using sandpaper, you need a few essential tools and materials.

- Sandpaper sheets or discs in various grits

- Flat substrate (e.g., a glass or marble surface)

- Water or lubricant (optional)

- Chisel or bevel gauge

- Clamping device (e.g., a vise or bench clamp)

In sharpening chisels with sandpaper, each of these tools serves a specific purpose that enhances the sharpening process and effectiveness.

-

Sandpaper Sheets or Discs: The sandpaper used for sharpening chisels comes in various grits. Coarse grits (around 60 to 120) are for initial shaping. Medium grits (around 220 to 400) refine the edge, while fine grits (600 and above) polish the blade for a razor-sharp finish. High-quality sandpaper, like aluminum oxide or silicon carbide, is recommended for durability and effective sharpening.

-

Flat Substrate: The flat substrate provides a stable and level surface for the sandpaper. A piece of glass or a marble slab is ideal because it is flat and easy to clean. The flatness of the substrate ensures that the chisel edge remains straight and that sharpening occurs evenly along the blade. Maintaining a flat profile is crucial for achieving optimal cutting performance.

-

Water or Lubricant: Using water or a lubricant can help reduce friction during the sharpening process. This application prevents the sandpaper from clogging and assists in achieving a smoother finish. Some users prefer using water, while others opt for honing oil based on personal preference.

-

Chisel or Bevel Gauge: The chisel is the primary tool being sharpened. A bevel gauge helps maintain the correct angle while sharpening. Most chisels require a sharpening angle of around 25 to 30 degrees. Consistency in angle is vital for ensuring that the blade achieves the desired sharpness and cutting efficiency.

-

Clamping Device: A clamping device, such as a vise or bench clamp, holds the chisel securely while sharpening. This stability allows for safer and more controlled sharpening motions. Proper clamping also helps prevent accidental slips that could lead to injury or blade damage. Some woodworkers recommend specific clamping techniques to preserve the integrity of the chisel’s edge.

These tools collectively enhance the sharpening process, offering varying perspectives based on user preferences and sharpening techniques.

What Common Mistakes Should You Avoid When Sharpening Chisels with Sandpaper?

When sharpening chisels with sandpaper, you should avoid several common mistakes to ensure a sharp and effective edge.

- Using the wrong grit of sandpaper

- Applying excessive pressure while sharpening

- Failing to maintain the proper angle

- Neglecting to clean the sandpaper

- Inconsistent motion during sharpening

- Ignoring the burr formation

- Not evaluating the chisel after sharpening

- Over-reliance on sandpaper

To understand these mistakes better, let’s examine each one in detail.

-

Using the Wrong Grit of Sandpaper: Using the wrong grit affects the sharpening outcome. Coarse grits (like 60-80) remove material quickly but can leave deep scratches. Fine grits (like 400-800) create a polished edge but are ineffective for reshaping the chisel. Selecting the appropriate grit is crucial for achieving the desired sharpness.

-

Applying Excessive Pressure While Sharpening: When sharpening, excessive pressure can damage both the chisel and the sandpaper. It can lead to uneven sharpening and can also cause heat buildup, which might affect the temper of the steel. A light and consistent pressure is essential for optimal results.

-

Failing to Maintain the Proper Angle: Maintaining the correct angle while sharpening is vital. Most chisels require an angle between 20 to 30 degrees. If the angle is too steep or too shallow, it can cause the edge to dull quickly or chip. Using guides can help keep the angle consistent.

-

Neglecting to Clean the Sandpaper: Over time, sandpaper can clog with steel shavings and debris. Neglecting to clean it reduces its effectiveness. Regularly tapping or brushing off the surface can prolong its life and improve sharpening performance.

-

Inconsistent Motion During Sharpening: Inconsistent motion can create uneven wear on the chisel edge. Maintaining a steady, even motion ensures a uniform edge. Using a straight edge or guide can help achieve this consistency.

-

Ignoring the Burr Formation: Burrs are small raised edges that form on the opposite side of the bevel during sharpening. Ignoring these can result in a dulling effect. Properly removing the burr is necessary for achieving a sharp edge.

-

Not Evaluating the Chisel After Sharpening: After sharpening, evaluating the edge is crucial. A quick visual inspection can help identify imperfections. Testing the sharpness by cutting into wood can further assess how well the chisel performs.

-

Over-Reliance on Sandpaper: Relying solely on sandpaper for sharpening can limit the effectiveness of the chisel’s edge. Some woodworkers recommend incorporating honing stones for final finishing. Using a combination of methods can produce the best results.